Infiniti F50. Manual - part 540

CAMSHAFT

EM-47

C

D

E

F

G

H

I

J

K

L

M

A

EM

3.

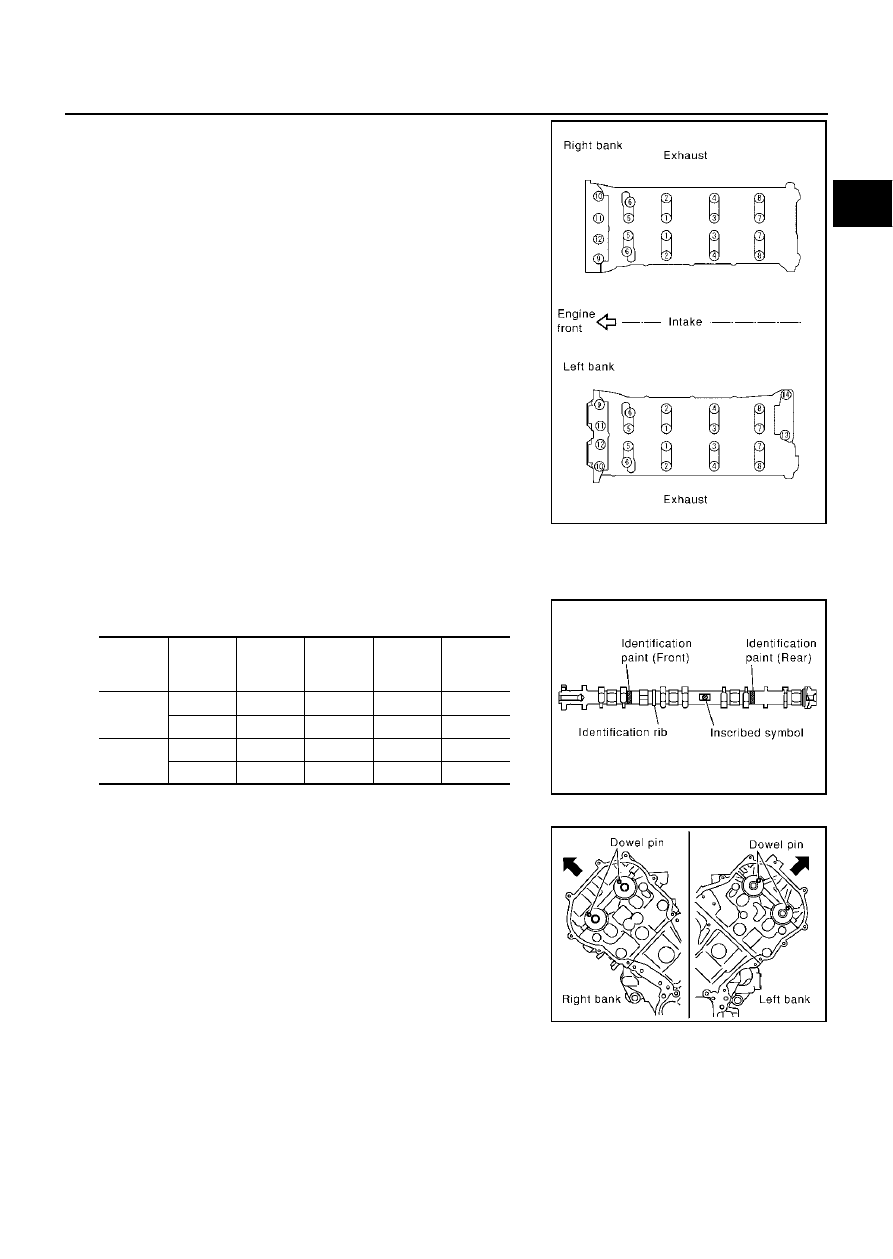

Loosen fixing bolts in the reverse order of that shown in figure to

remove camshaft brackets.

●

Lightly tapping with plastic hammer, remove No. 1 camshaft

bracket and No. 6 camshaft bracket.

NOTE:

The bottom surface of each bracket will be stuck to cylinder

head because of liquid gasket.

4.

Remove camshaft.

5.

Remove adjusting shims and valve lifters if necessary.

●

Correctly identify location where each part is installed. Keep

parts in an organized way to avoid mixing them up.

INSTALLATION

1.

Install adjusting shims and valve lifters if necessary.

●

Install removed parts in the same locations as before.

2.

Install camshafts. Refer to the table below for identification of

right and left bank, and intake and exhaust.

●

Install so that dowel pin at the front of camshaft face is in the

direction shown in the figure.

PBIC0031E

Bank

IN/EX

Identifica-

tion paint

(front)

Identifica-

tion paint

(rear)

Identifica-

tion rib

Identifica-

tion sym-

bol

LH

IN

Blue

—

No.

LH

EXH

—

Orange

No.

LH

RH

INT

Blue

—

Yes.

RH

EXH

—

Orange

Yes.

RH

PBIC0032E

SBIA0366E