Infiniti F50. Manual - part 477

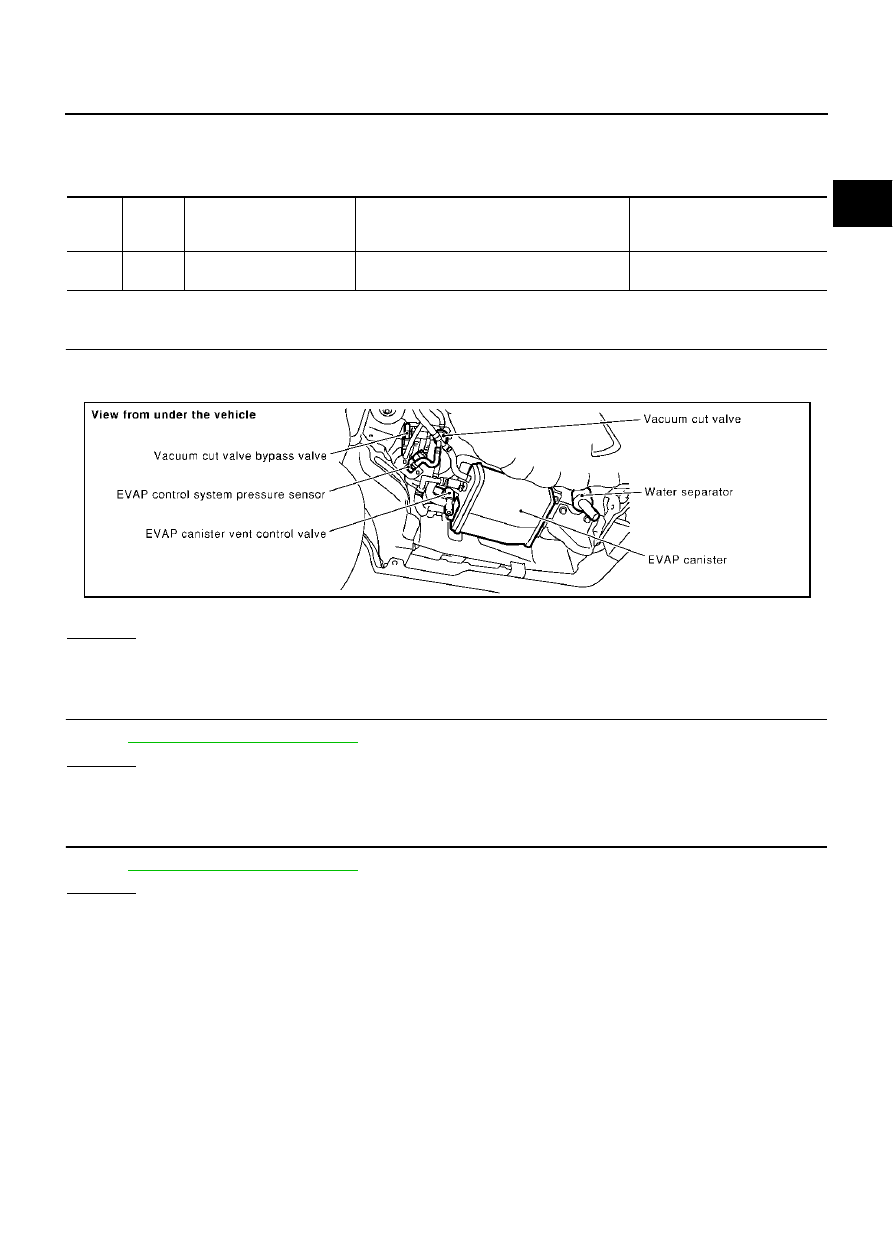

DTC P1446 EVAP CANISTER VENT CONTROL VALVE

EC-549

C

D

E

F

G

H

I

J

K

L

M

A

EC

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

Diagnostic Procedure

ABS002QQ

1.

CHECK RUBBER TUBE

1.

Turn ignition switch “OFF”.

2.

Disconnect rubber tube connected to EVAP canister vent control valve.

3.

Check the rubber tube for clogging.

OK or NG

OK

>> GO TO 2.

NG

>> Clean rubber tube using an air blower.

2.

CHECK WATER SEPARATOR

Refer to

EC-338, "Component Inspection"

OK or NG

OK

>> GO TO 3.

NG

>> Clean or replace water separator.

3.

CHECK EVAP CANISTER VENT CONTROL VALVE

Refer to

EC-551, "Component Inspection"

OK or NG

OK

>> GO TO 4.

NG

>> Replace EVAP canister vent control valve.

TER-

MINAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

158

L/Y

EVAP canister vent control

valve

[Ignition switch “ON”]

BATTERY VOLTAGE

(11 - 14V)

PBIB0026E