Infiniti F50. Manual - part 458

DTC P1144, P1164 HO2S1

EC-473

C

D

E

F

G

H

I

J

K

L

M

A

EC

4.

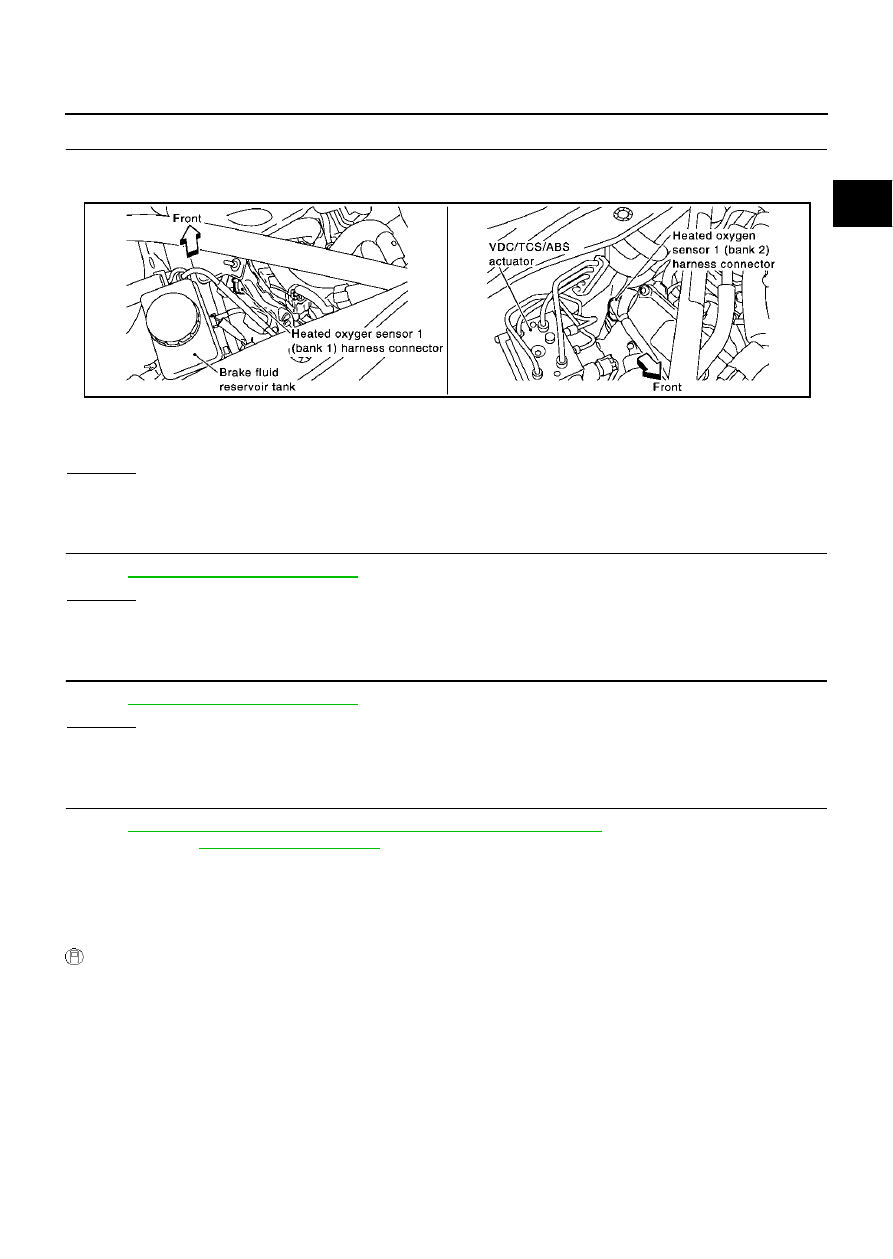

CHECK HO2S1 CONNECTOR FOR WATER

1.

Turn ignition switch “OFF”.

2.

Disconnect heated oxygen sensor 1 harness connector.

3.

Check connectors for water.

OK or NG

OK

>> GO TO 5.

NG

>> Repair or replace harness or connectors.

5.

CHECK HEATED OXYGEN SENSOR 1 HEATER

Refer to

EC-162, "Component Inspection"

OK or NG

OK

>> GO TO 6.

NG

>> Replace malfunctioning heated oxygen sensor 1.

6.

CHECK HEATED OXYGEN SENSOR 1

Refer to

EC-473, "Component Inspection"

OK or NG

OK

>> GO TO 7.

NG

>> Replace malfunctioning heated oxygen sensor 1.

7.

CHECK INTERMITTENT INCIDENT

Refer to

EC-132, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT"

For circuit, refer to

>> INSPECTION END

Component Inspection

EBS00MIU

HEATED OXYGEN SENSOR 1

With CONSULT-II

1.

Start engine and warm it up to normal operating temperature.

Water should not exist.

PBIB1250E