Infiniti F50. Manual - part 423

DTC P0442 EVAP CONTROL SYSTEM

EC-333

C

D

E

F

G

H

I

J

K

L

M

A

EC

2.

CHECK FUEL FILLER CAP INSTALLATION

Check that the cap is tightened properly by rotating the cap clockwise.

OK or NG

OK

>> GO TO 3.

NG

>> 1. Open fuel filler cap, then clean cap and fuel filler neck threads using air blower.

2. Retighten until ratcheting sound is heard.

3.

CHECK FUEL FILLER CAP FUNCTION

Check for air releasing sound while opening the fuel filler cap.

OK or NG

OK

>> GO TO 5.

NG

>> GO TO 4.

4.

CHECK FUEL TANK VACUUM RELIEF VALVE

Refer to

EC-687, "FUEL TANK VACUUM RELIEF VALVE (BUILT INTO FUEL FULLER CAP)"

.

OK or NG

OK

>> GO TO 5.

NG

>> Replace fuel filler cap with a genuine one.

5.

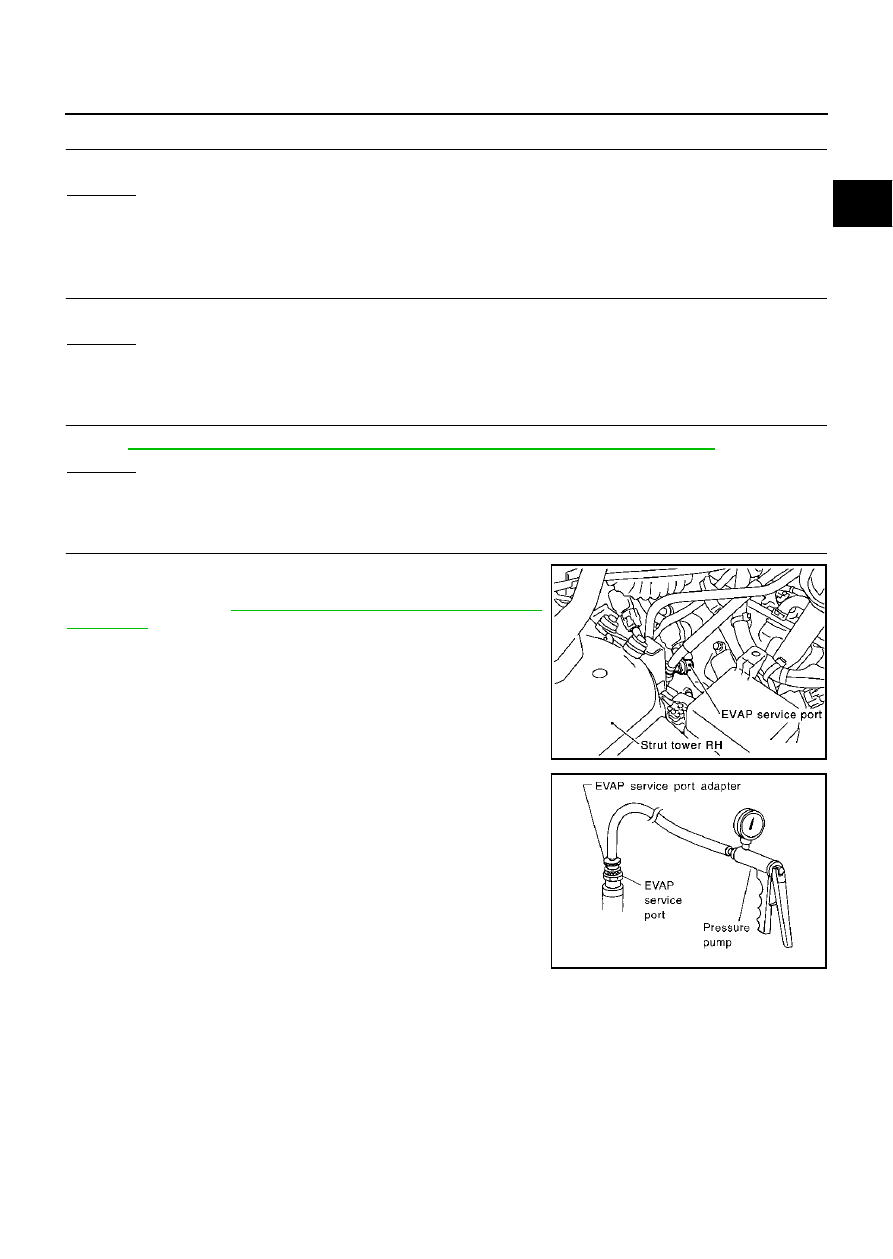

INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service port securely. For the location of EVAP

service port, refer to

EC-685, "EVAPORATIVE EMISSION LINE

NOTE:

Improper installation of the EVAP service port adapter to the

EVAP service port may cause leaking.

Models with CONSULT-II>>GO TO 6.

Models without CONSULT-II>>GO TO 7.

PBIB1251E

SEF916U