Infiniti F50. Manual - part 279

TROUBLE DIAGNOSIS

BRC-59

C

D

E

G

H

I

J

K

L

M

A

B

BRC

3.

CHECKING SELF-DIAGNOSIS RESULTS (2)

1.

Connect VDC/TCS/ABS control unit and steering angle sensor connector.

2.

Connect battery negative terminal. Turn ignition switch ON.

3.

Erase self-diagnosis results. Then start engine and perform self-diagnosis.

Does only “STEERING ANGLE SENSOR COMMUNICATION SYSTEM” appear on self-diagnosis results dis-

play?

YES

>> Check spiral cable (Replace steering angle sensor and adjust steering angle sensor neutral posi-

BRC-6, "Adjustment of Steering Angle Sensor Neutral Position"

NO

>> GO TO 4.

4.

CAN COMMUNICATION SYSTEM CHECK

Check “CAN DIAGNOSIS SUPPORT MONITOR” of data monitor items.

>> Print out monitor items. Then refer to CAN system

LAN-24, "CAN SYSTEM (FOR VDC MOD-

LAN-40, "CAN SYSTEM (FOR ICC MODELS)"

.

Inspecting Components

EFS001ZS

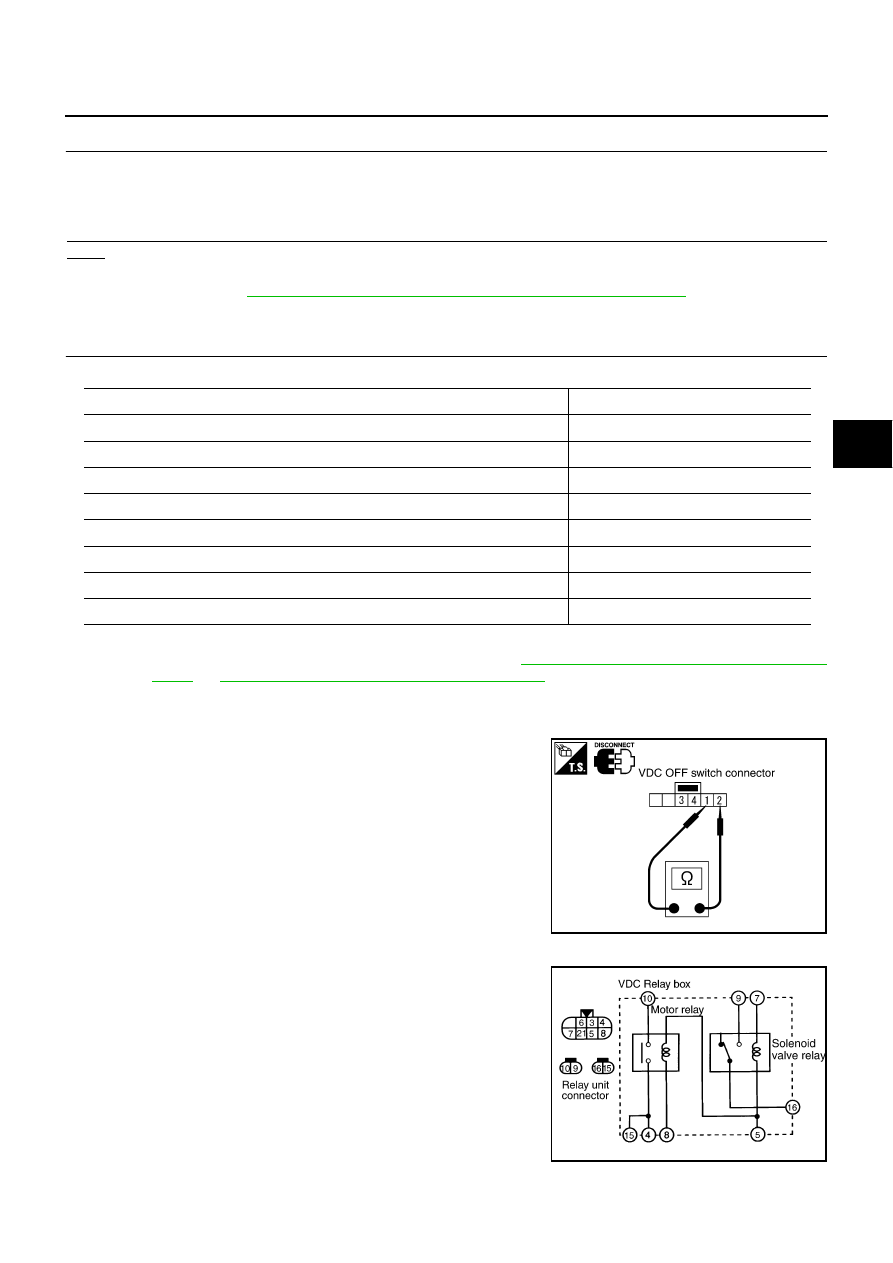

VDC OFF SWITCH

●

Disconnect VDC OFF switch connector. Check continuity

between terminal No. 1 and terminal No. 2.

VDC RELAY BOX

Disconnect VDC relay box connector. Check continuity, resistance

value, and insulation between any pair of terminals in VDC relay box.

Normal

Error (example)

Models with ICC system

Models without ICC system

CAN COMM: OK

CAN COMM: OK

CAN COMM: OK

CAN CIRC1: OK

CAN CIRC1: OK

CAN CIRC 1: UNKWN

CAN CIRC 2: OK

CAN CIRC 2: OK

CAN CIRC 2: UNKWN

CAN CIRC3: OK

CAN CIRC3: OK

CAN CIRC 3: UNKWN

CAN CIRC 4: OK

CAN CIRC 4: OK

CAN CIRC 4: UNKWN

CAN CIRC 5: OK

CAN CIRC 5: UNKWN

CAN CIRC 5: UNKWN

CAN CIRC 6: OK

CAN CIRC 6: OK

CAN CIRC 6: UNKWN

No. 1 to No. 2:

Pressing switch will establish continuity, releasing

it will break continuity.

SFIA0848E

SFIA0882E