Infiniti F50. Manual - part 156

REFRIGERANT LINES

ATC-149

C

D

E

F

G

H

I

K

L

M

A

B

ATC

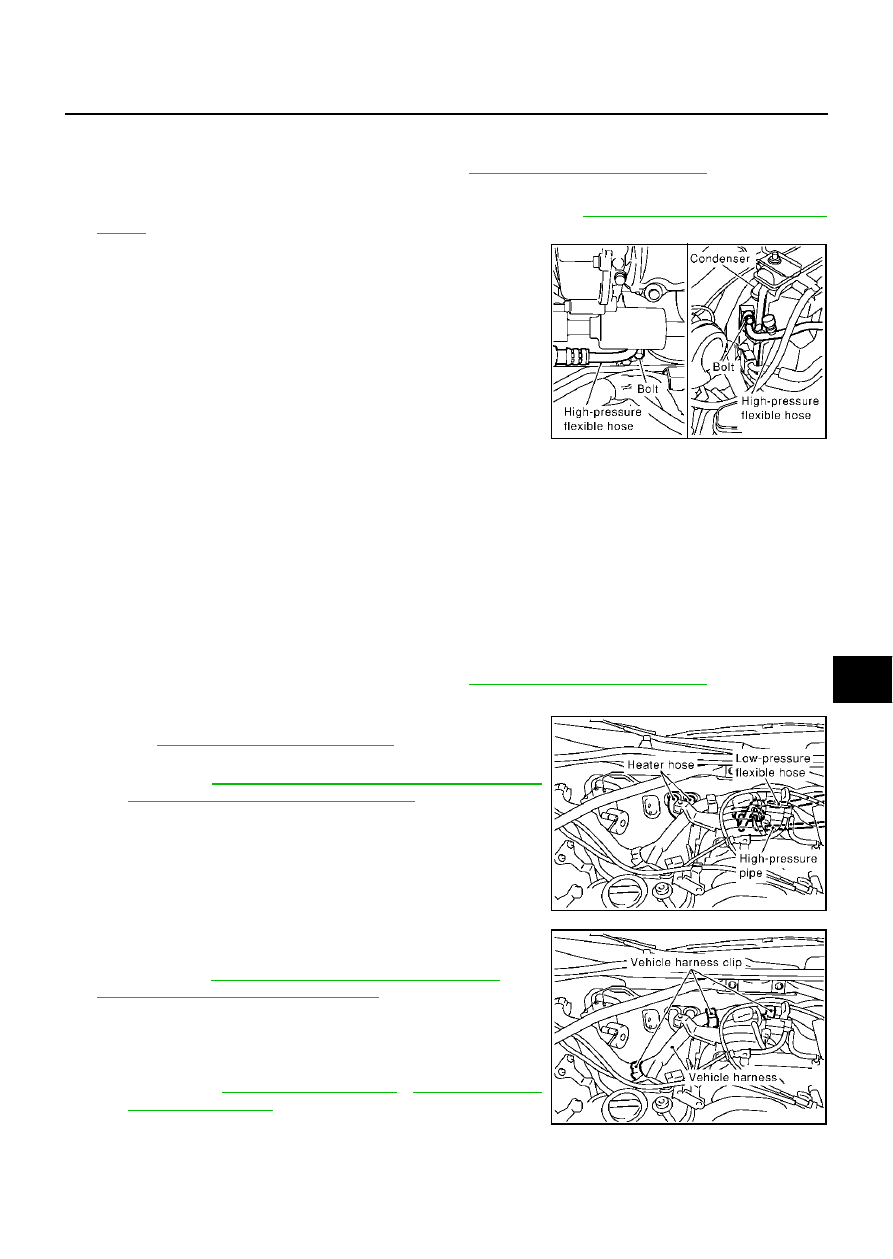

High-Pressure Flexible Hose

EJS000A8

REMOVAL

1.

Remove engine cover and air cleaner cover. Refer to

2.

Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

3.

Remove air cleaner assembly, air duct and air inlet pipe. Refer to

4.

Remove mounting bolt and nut from the high-pressure flexible

hose, then remove it.

CAUTION:

Cap or wrap the open ends of the pipe with a suitable material

such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

●

Replace high-pressure flexible hose O-ring with a new one. Apply compressor oil prior to installa-

tion.

●

When pouring refrigerant, check for leaks.

High-Pressure Pipe

EJS000A9

REMOVAL

1.

Remove engine cover and air cleaner cover. Refer to

2.

Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

3.

Drain coolant from cooling system and disconnect heater hoses.

Refer to

CO-9, "Changing Engine Coolant"

.

4.

Remove tower bar, air cleaner assembly, air duct and air inlet

pipe. Refer to

FSU-5, "FRONT SUSPENSION ASSEMBLY"

and

EM-15, "AIR CLEANER AND AIR DUCT"

.

5.

Remove vehicle harness from the clip.

6.

Remove low-pressure flexible hose and high-pressure flexible

hose. Refer to

ATC-148, "Low-Pressure Flexible Hose"

ATC-149, "High-Pressure Flexible Hose"

.

CAUTION:

Cap or wrap the open ends of the pipe with a suitable mate-

rial such as vinyl tape to avoid the entry of air.

7.

Remove front grille, battery, battery tray and radiator mounting

bracket. Refer to

and

.

8.

Slide the radiator assembly to the right side of vehicle.

RJIA0138E

Bolt and nut mounting high-pressure flexible hose

Tightening torque

: 7.8 - 19.6 N·m (0.8 - 1.9 kg·m, 69 - 173 in-lb)

RJIA0318E

RJIA0328E