Infiniti F50. Manual - part 155

REFRIGERANT LINES

ATC-145

C

D

E

F

G

H

I

K

L

M

A

B

ATC

Compressor Clutch

EJS000KF

REMOVAL

Overhaul

1.

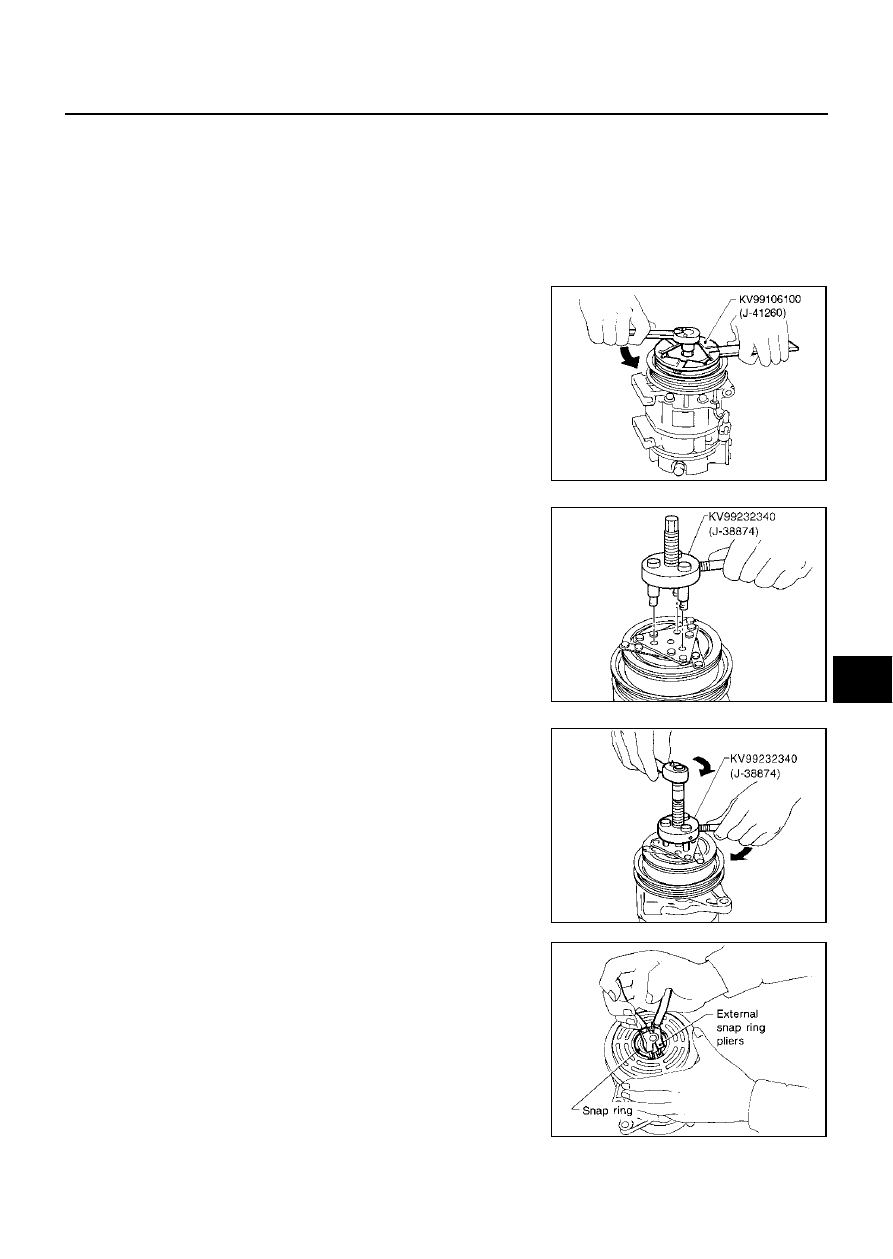

When removing center bolt, hold clutch disc with a wrench.

2.

Remove clutch disc using the clutch disc puller.

3.

Remove snap ring using external snap ring pliers.

Nut mounting the high-pressure flexible hose

Tightening torque

: 7.8 - 19.6 N·m (0.8 - 1.9 kg·m, 69 - 173 in-lb)

Nut mounting the low-pressure flexible hose

Tightening torque

: 7.8 - 19.6 N·m (0.8 - 1.9 kg·m, 69 - 173 in-lb)

RHA136EB

RHA399F

RHA124F

RHA138E