Infiniti G37 Coupe. Manual - part 629

CAMSHAFT

EM-91

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

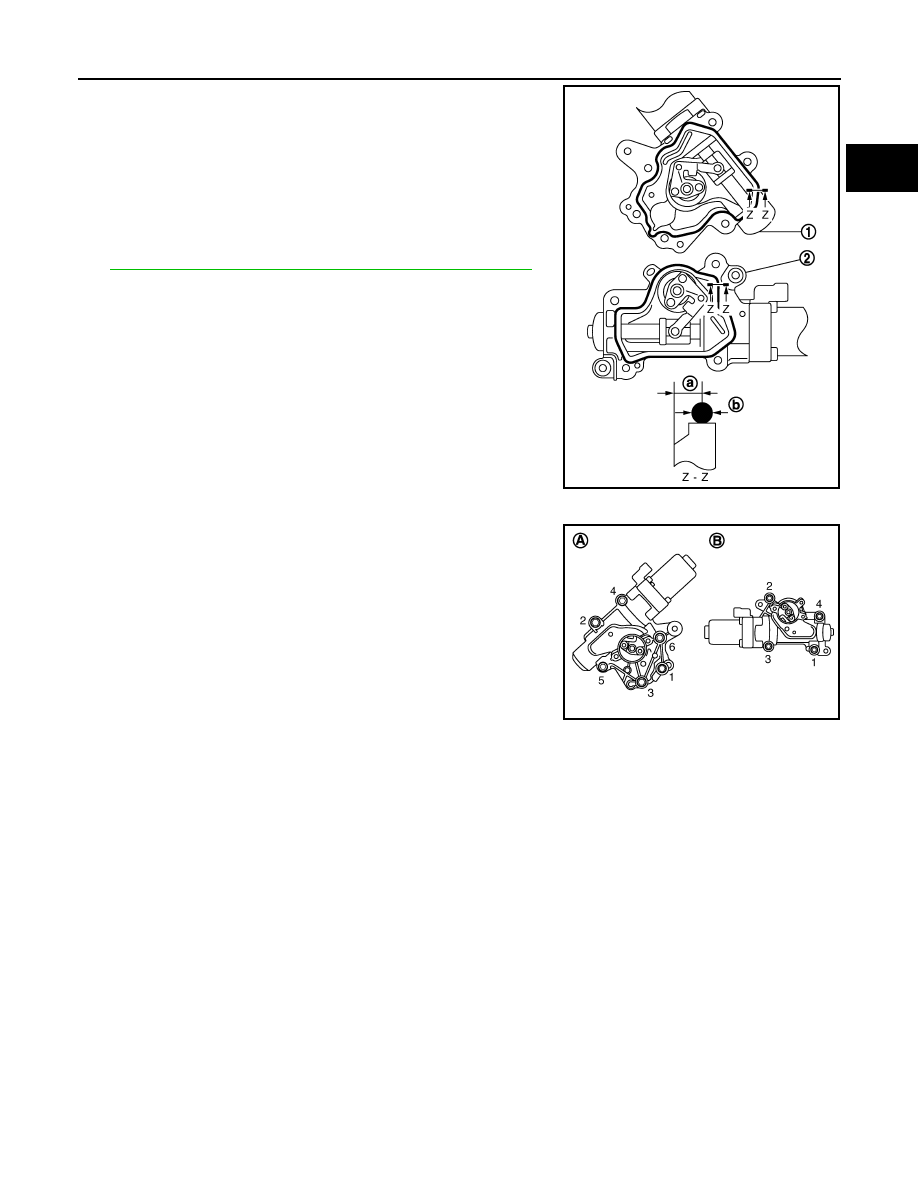

c.

Apply a continuous bead of liquid gasket with tube presser

(commercial service tool) to the VVEL actuator sub assembly as

shown in the figure.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-15, "Recommended Chemical Products and Sealants"

.

CAUTION:

Never apply gasket to the oil passage.

d.

Install new VVEL actuator sub assembly.

• Tighten mounting bolts in the following step, in numerical order

as shown.

CAUTION:

• When installing, be careful with VVEL actuator sub

assembly (bank 2) mounting bolt No. 1 because its length

is different.

• Be sure to check that the VVEL actuator sub assembly is

in contact with the cylinder head before tightening the

mounting bolts.

e.

Remove holding jig.

f.

Check that VVEL actuator arm bolt hole is aligned with control shaft tapped hole. If it is not aligned, turn

control shaft for alignment.

1

: VVEL actuator sub assembly (bank 2)

2

: VVEL actuator sub assembly (bank 1)

a

: 4.0 - 5.6 mm (0.157 - 0.220 in)

b

: 3.4 - 4.4 mm (0.134 - 0.173 in) dia.

JPBIA1125ZZ

A

: Bank 2

B

: Bank 1

JPBIA1114ZZ