Infiniti G37 Coupe. Manual - part 540

P0507 ISC SYSTEM

EC-341

< COMPONENT DIAGNOSIS >

[VQ37VHR]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0507 ISC SYSTEM

Description

INFOID:0000000001910897

The ECM controls the engine idle speed to a specified level through the fine adjustment of the air, which is let

into the intake manifold, by operating the electric throttle control actuator. The operating of the throttle valve is

varied to allow for optimum control of the engine idling speed. The crankshaft position sensor (POS) detects

the actual engine speed and sends a signal to the ECM.

The ECM controls the electric throttle control actuator so that the engine speed coincides with the target value

memorized in the ECM. The target engine speed is the lowest speed at which the engine can operate steadily.

The optimum value stored in the ECM is determined by taking into consideration various engine conditions,

such as during warming up, deceleration, and engine load (air conditioner, power steering and cooling fan

operation, etc.).

DTC Logic

INFOID:0000000001734161

DTC DETECTION LOGIC

NOTE:

If DTC P0507 is displayed with other DTC, first perform the trouble diagnosis for the other DTC.

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conduct-

ing the next test.

1.

Turn ignition switch OFF and wait at least 10 seconds.

2.

Turn ignition switch ON.

3.

Turn ignition switch OFF and wait at least 10 seconds.

If the target idle speed is out of the specified value, perform

EC-19, "IDLE AIR VOLUME LEARNING :

, before conducting DTC Confirmation Procedure.

TESTING CONDITION:

• Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

• Always perform the test at a temperature above

−

10

°

C(14

°

F).

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Start engine and warm it up to normal operating temperature.

2.

Turn ignition switch OFF and wait at least 10 seconds.

3.

Turn ignition switch ON.

4.

Turn ignition switch OFF and wait at least 10 seconds.

5.

Start engine and run it for at least 1 minute at idle speed.

6.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000001734162

1.

CHECK PCV HOSE CONNECTION

Confirm that PCV hose is connected correctly.

Is the inspection result normal?

YES

>> GO TO 2.

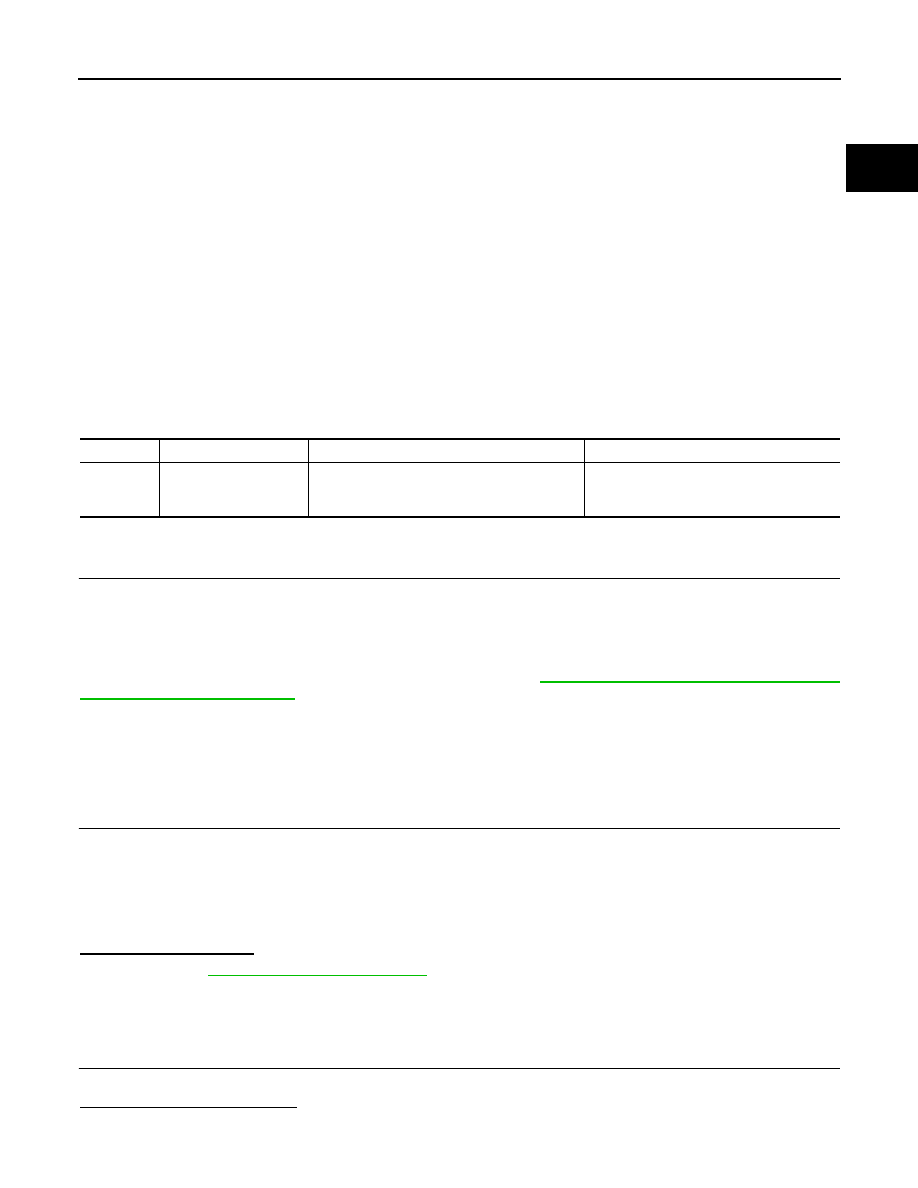

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0507

Idle speed control sys-

tem RPM higher than

expected

The idle speed is more than the target idle

speed by 200 rpm or more.

• Electric throttle control actuator

• Intake air leak

• PCV system