Infiniti G37 Coupe. Manual - part 507

P0133, P0153 A/F SENSOR 1

EC-209

< COMPONENT DIAGNOSIS >

[VQ37VHR]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

>> Repair or replace malfunctioning part.

7.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Turn ignition switch OFF and wait at least 10 seconds.

2.

Turn ignition switch ON.

3.

Turn ignition switch OFF and wait at least 10 seconds.

4.

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1minute under no load.

5.

Let engine idle for 1 minute.

6.

Increase the engine speed up to about 3,600 rpm and keep it for 10 seconds.

7.

Fully release accelerator pedal and then let engine idle for about 1 minute.

8.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000001734044

1.

CHECK GROUND CONNECTION

1.

Turn ignition switch OFF.

2.

Check ground connection M95. Refer to Ground Inspection in

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

RETIGHTEN A/F SENSOR 1

Loosen and retighten the A/F sensor 1. Refer to

EM-33, "Removal and Installation"

.

>> GO TO 3.

3.

CHECK EXHAUST GAS LEAK

1.

Start engine and run it at idle.

2.

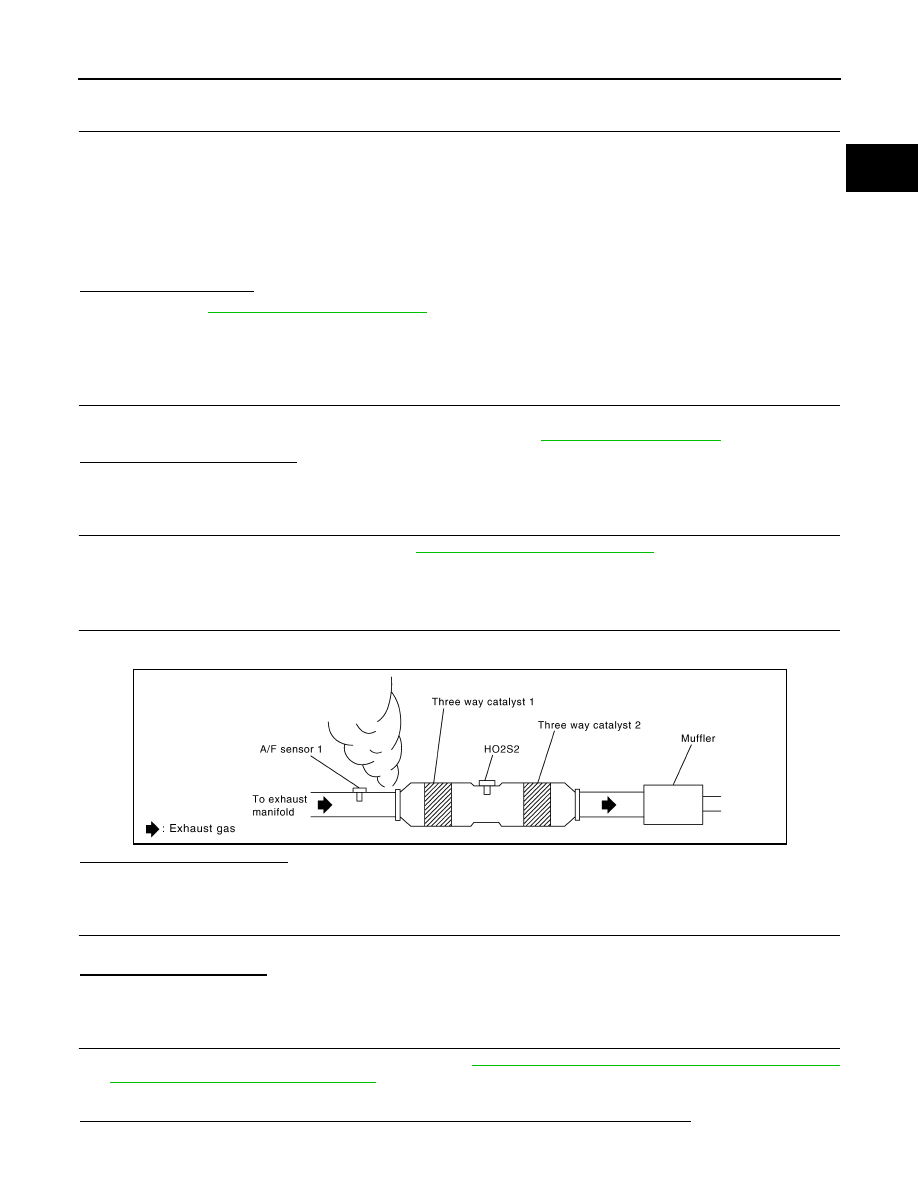

Listen for an exhaust gas leak before three way catalyst 1.

Is exhaust gas leak detected?

YES

>> Repair or replace.

NO

>> GO TO 4.

4.

CHECK FOR INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

Is intake air leak detected?

YES

>> Repair or replace.

NO

>> GO TO 5.

5.

CLEAR THE MIXTURE RATIO SELF-LEARNING VALUE

1.

Clear the mixture ratio self-learning value. Refer to

EC-22, "MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement"

.

2.

Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0171, P172, P0174 or P0175 detected? Is it difficult to start engine?

PBIB1922E