Infiniti G37 Coupe. Manual - part 454

DLN-130

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R200V]

DRIVE PINION

9.

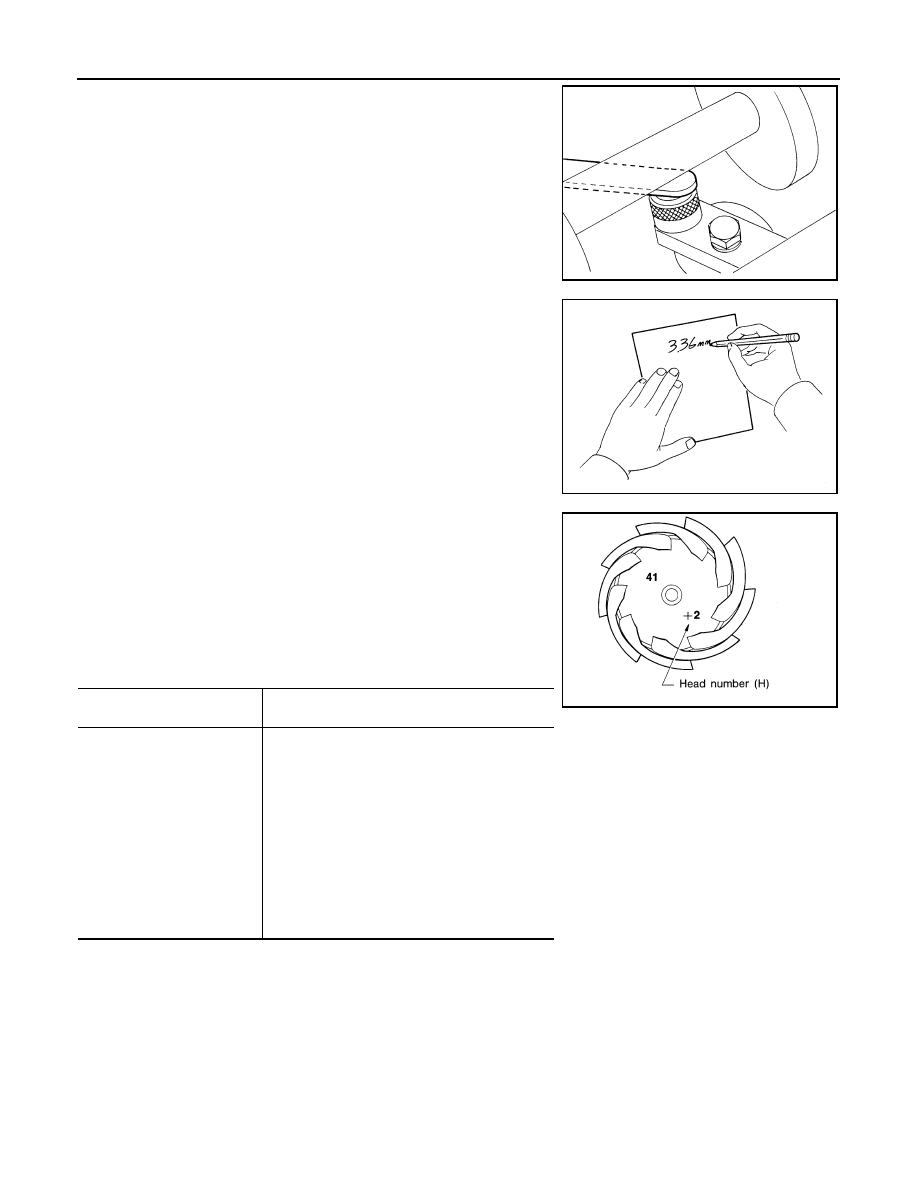

Select the correct standard pinion height adjusting washer thick-

ness. Select by using a standard gauge of 3 mm (0.12 in) and

your J-34309-101 feeler gauge. Measure the distance between

the J-34309-11 pinion height adapter including the standard

gauge and the arbor.

10. Write down exact measurement (the value of feeler gauge).

11. Correct the pinion height washer size by referring to the “pinion

head number”.

There are two numbers painted on the drive pinion. The first

one refers to the drive pinion and drive gear as a matched

set. This number should be the same as the number on the

drive gear. The second number is the “pinion head height

number”. It refers to the ideal pinion height from standard

for quietest operation. Use the following chart to determine

the correct pinion height washer.

12. Select the correct pinion height adjusting washer.

SPD204A

SPD775

Pinion head height number

Add or remove from the standard pinion height ad-

justing washer thickness measurement

−

6

−

5

−

4

−

3

−

2

−

1

0

+1

+2

+3

+4

+5

+6

Add 0.06 mm (0.0024 in)

Add 0.05 mm (0.0020 in)

Add 0.04 mm (0.0016 in)

Add 0.03 mm (0.0012 in)

Add 0.02 mm (0.0008 in)

Add 0.01 mm (0.0004 in)

Use the selected washer thickness

Subtract 0.01 mm (0.0004 in)

Subtract 0.02 mm (0.0008 in)

Subtract 0.03 mm (0.0012 in)

Subtract 0.04 mm (0.0016 in)

Subtract 0.05 mm (0.0020 in)

Subtract 0.06 mm (0.0024 in)

SPD542