Infiniti G37 Coupe. Manual - part 281

BRC-98

< PRECAUTION >

[VDC/TCS/ABS]

PRECAUTIONS

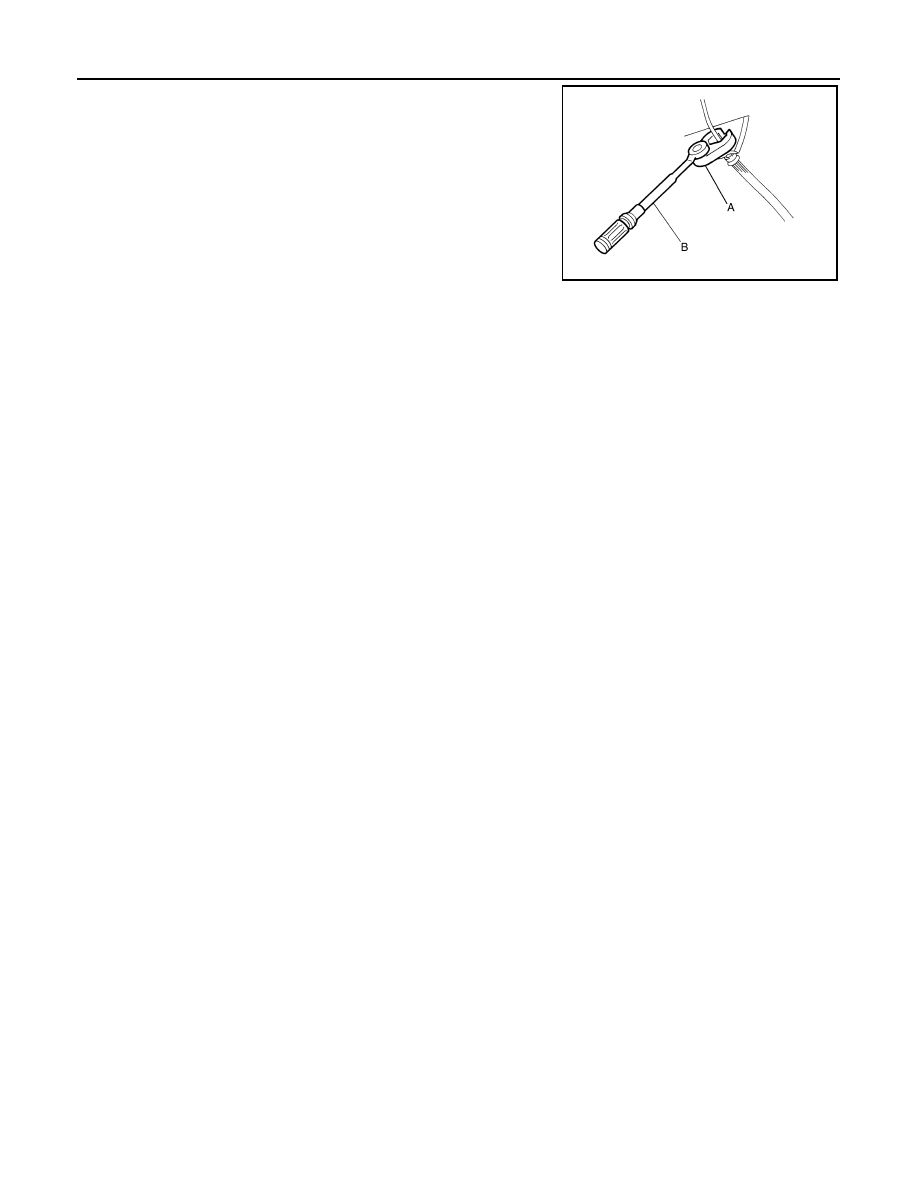

• Tighten the brake tube flare nut to the specified torque with a crow-

foot (A) and torque wrench (B).

• Always conform the specified tightening torque when installing the

brake pipes.

• Brake system is an important safety part. If a brake fluid leak is

detected, always disassemble the affected part. If a malfunction is

detected, replace part with a new one.

• Turn the ignition switch OFF and disconnect the ABS actuator and

electric unit (control unit) connector or the battery negative terminal

before performing the work.

Precaution for Brake Control

INFOID:0000000001635158

• When starting engine or when starting vehicle just after starting engine, brake pedal may vibrate or motor

operating noise may be heard from engine compartment. This is normal condition.

• When an error is indicated by ABS or another warning lamp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for estimate causes before starting diagnos-

tic servicing. Besides electrical system inspection, check brake booster operation, brake fluid level, and oil

leaks.

• If tire size and type are used in an improper combination, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

• ABS might be out of order or malfunctions by putting a radio (wiring inclusive), an antenna and a lead-in wire

near the control unit.

• If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

• VDC system may not operate normally or a VDC OFF indicator lamp or SLIP indicator lamp may light.

- When replacing the following parts with parts other than genuine parts or making modifications: Suspension

related parts (shock absorber, spring, bushing, etc.), tires, wheels (other than specified sizes), brake-related

parts (pad, rotor, caliper, etc.), engine-related parts (muffler, ECM, etc.) and body reinforcement-related parts

(roll bar, tower bar, etc.).

- When driving with worn or deteriorated suspension, tires and brake-related parts.

JPFIA0001ZZ