Content .. 1345 1346 1347 1348 ..

Infiniti G37 Coupe. Manual - part 1347

A/T FLUID TEMPERATURE SENSOR 2

TM-241

< ON-VEHICLE REPAIR >

[5AT: RE5R05A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

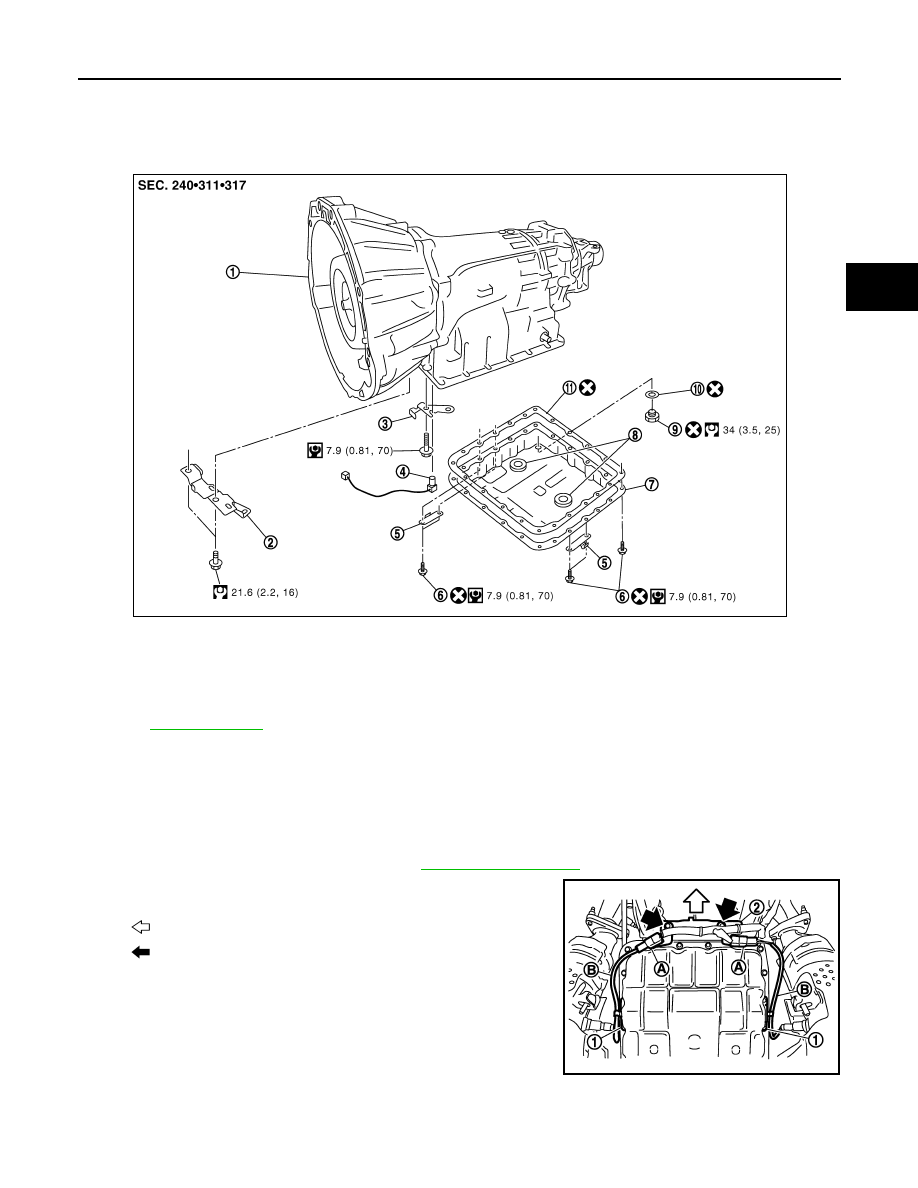

A/T FLUID TEMPERATURE SENSOR 2

Exploded View

INFOID:0000000001672263

Removal and Installation

INFOID:0000000001672264

REMOVAL

1.

Disconnect the battery cable from the negative terminal.

2.

Drain ATF through drain plug.

3.

Remove exhaust mounting bracket. Refer to

4.

Disconnect heated oxygen sensor 2 harness connectors (A).

5.

Remove heated oxygen sensor 2 harness (B) from clips (1).

6.

Remove bracket (2) from transmission assembly.

1.

A/T

2.

Bracket

3.

Bracket

4.

A/T fluid temperature sensor 2

5.

Clip

6.

Oil pan mounting bolt

7.

Oil pan

8.

Magnet

9.

Drain plug

10. Drain plug gasket

11.

Oil pan gasket

Refer to

JSDIA0123GB

: Vehicle front

: Bolt

SCIA8269E