Content .. 1305 1306 1307 1308 ..

Infiniti G37 Coupe. Manual - part 1307

A/T CONTROL SYSTEM

TM-81

< FUNCTION DIAGNOSIS >

[5AT: RE5R05A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

• *1: Spare for vehicle speed sensor·A/T (revolution sensor)

• *2: Spare for accelerator pedal position signal

• *3: If these input and output signals are different, the TCM triggers the fail-safe function.

• *4: Used as a condition for starting self-diagnostics; if self-diagnostics are not started, it is judged that there is some kind of error.

• *5: Input by CAN communications.

• *6: Output by CAN communications.

CAN COMMUNICATION

CAN (Controller Area Network) is a serial communication line for real-time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independently). In CAN communication, control units are connected with 2

communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. Refer to

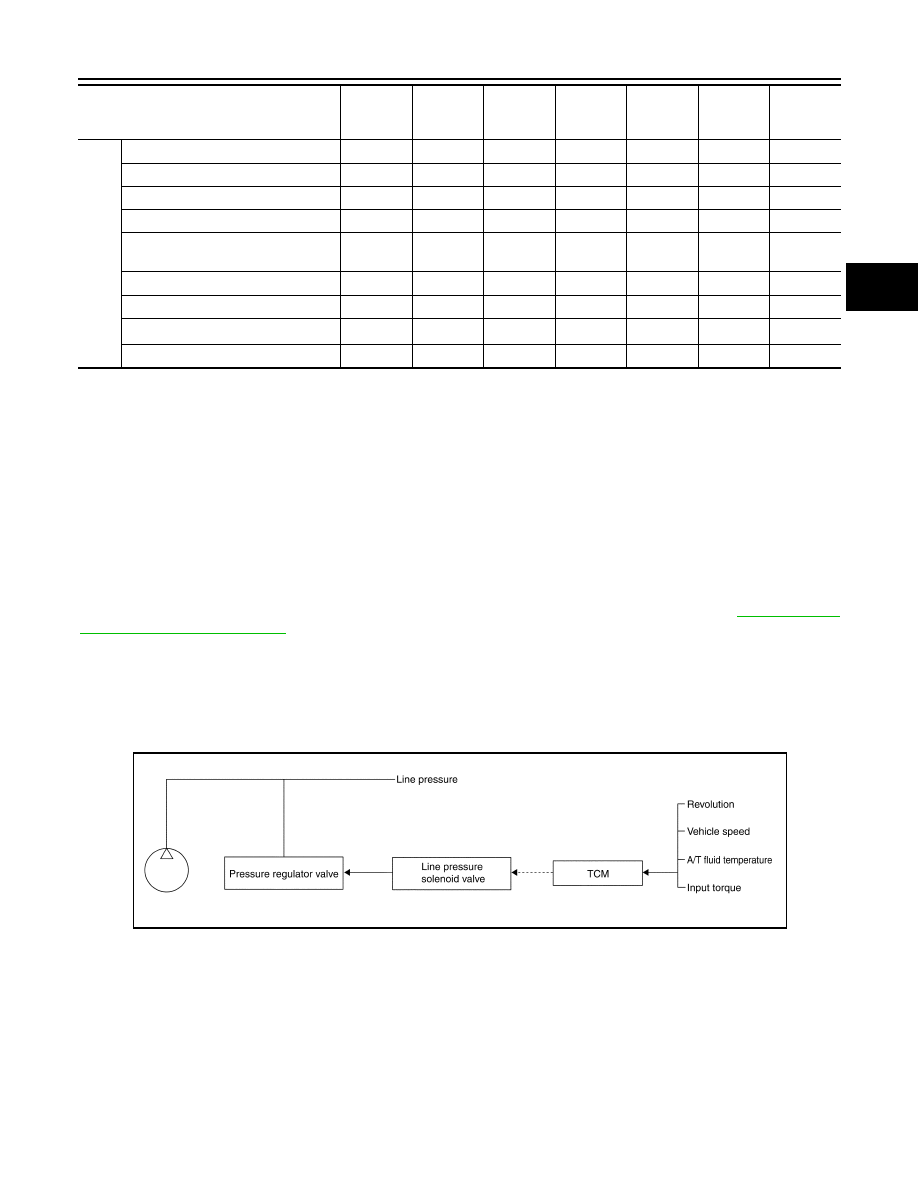

LINE PRESSURE CONTROL

• When an input torque signal equivalent to the engine drive force is transmitted from the ECM to the TCM,

the TCM controls the line pressure solenoid valve.

• This line pressure solenoid controls the pressure regulator valve as the signal pressure and adjusts the pres-

sure of the operating oil discharged from the oil pump to the line pressure most appropriate to the driving

state.

Line Pressure Control is Based On The TCM Line Pressure Characteristic Pattern

• The TCM has stored in memory a number of patterns for the optimum line pressure characteristic for the

driving state.

• In order to obtain the most appropriate line pressure characteristic to meet the current driving state, the TCM

controls the line pressure solenoid current value and thus controls the line pressure.

Normal Control

Out-

put

Direct clutch solenoid

X

X

X

X

Input clutch solenoid

X

X

X

X

High and low reverse clutch solenoid

X

X

X

X

Front brake solenoid

X

X

X

X

Low coast brake solenoid

(ATF pressure switch 2)

X

X

X

X

X

Line pressure solenoid

X

X

X

X

X

X

X

TCC solenoid

X

X

X

Self-diagnostics table

*6

X

Starter relay

X

X

Control item

Line

pressure

control

Vehicle

speed

control

Shift

control

Lock-up

control

Engine

brake

control

Fail-safe

function

*3

Self-diag-

nostics

function

PCIA0007E