Content .. 1100 1101 1102 1103 ..

Infiniti G37 Coupe. Manual - part 1102

SE-76

< COMPONENT DIAGNOSIS >

LIFTING MOTOR

LIFTING MOTOR

FRONT

FRONT : Description

INFOID:0000000001694120

With the power supplied to power seat switch, lifting motor operates the up and down movement of seat cush-

ion.

FRONT : Component Function Check

INFOID:0000000001694121

1.

CHECK LIFTING MOTOR FUNCTION

Check lifting operation with power seat switch.

Is the inspection results normal?

YES

>> Lifting motor is OK.

NO

>> Refer to

SE-76, "FRONT : Diagnosis Procedure"

FRONT : Diagnosis Procedure

INFOID:0000000001694122

1.

CHECK LIFTING MOTOR CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect lifting motor connector and power seat switch connector.

3.

Check continuity between lifting motor harness connector and power seat switch harness connector.

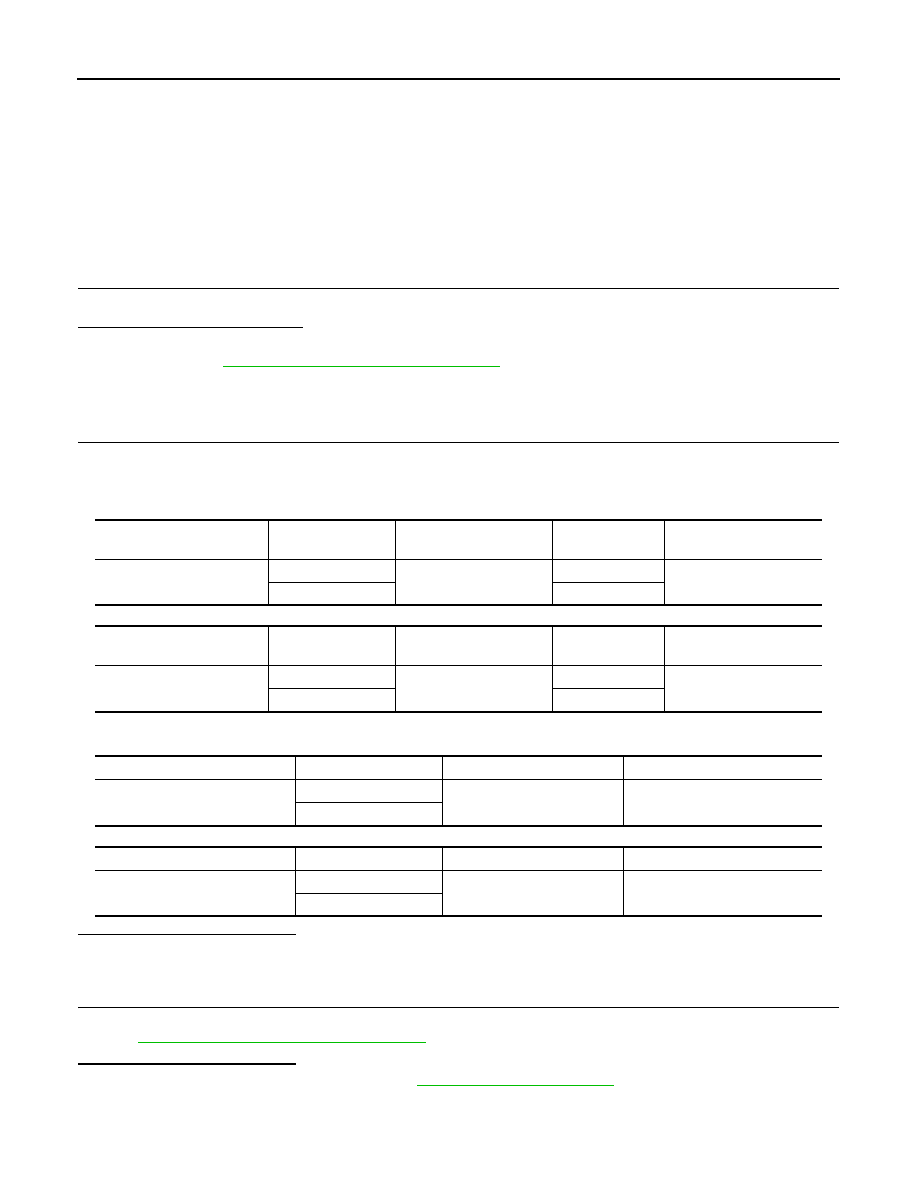

Driver side

Passenger side

4.

Check continuity between lifting motor harness connector and ground.

Driver side

Passenger side

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace circuit.

2.

CHECK LIFTING MOTOR

Check lifting motor.

Refer to

SE-77, "FRONT : Component Inspection"

.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-38, "Intermittent Incident"

.

NO

>> Replace lifting motor. (Built in seat cushion frame.)

Lifting motor connector

Terminal

Power seat switch con-

nector

Terminal

Continuity

B528

13

B511

13

Existed

28

28

Lifting motor connector

Terminal

Power seat switch con-

nector

Terminal

Continuity

B569

13

B554

13

Existed

28

28

Lifting motor connector

Terminal

Ground

Continuity

B528

13

Ground

Not existed

28

Lifting motor connector

Terminal

Ground

Continuity

B569

13

Ground

Not existed

28