Infiniti G35 (V35) Sedan. Manual - part 957

MWI

FUEL LEVEL SENSOR SIGNAL CIRCUIT

MWI-55

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

M

B

N

A

O

P

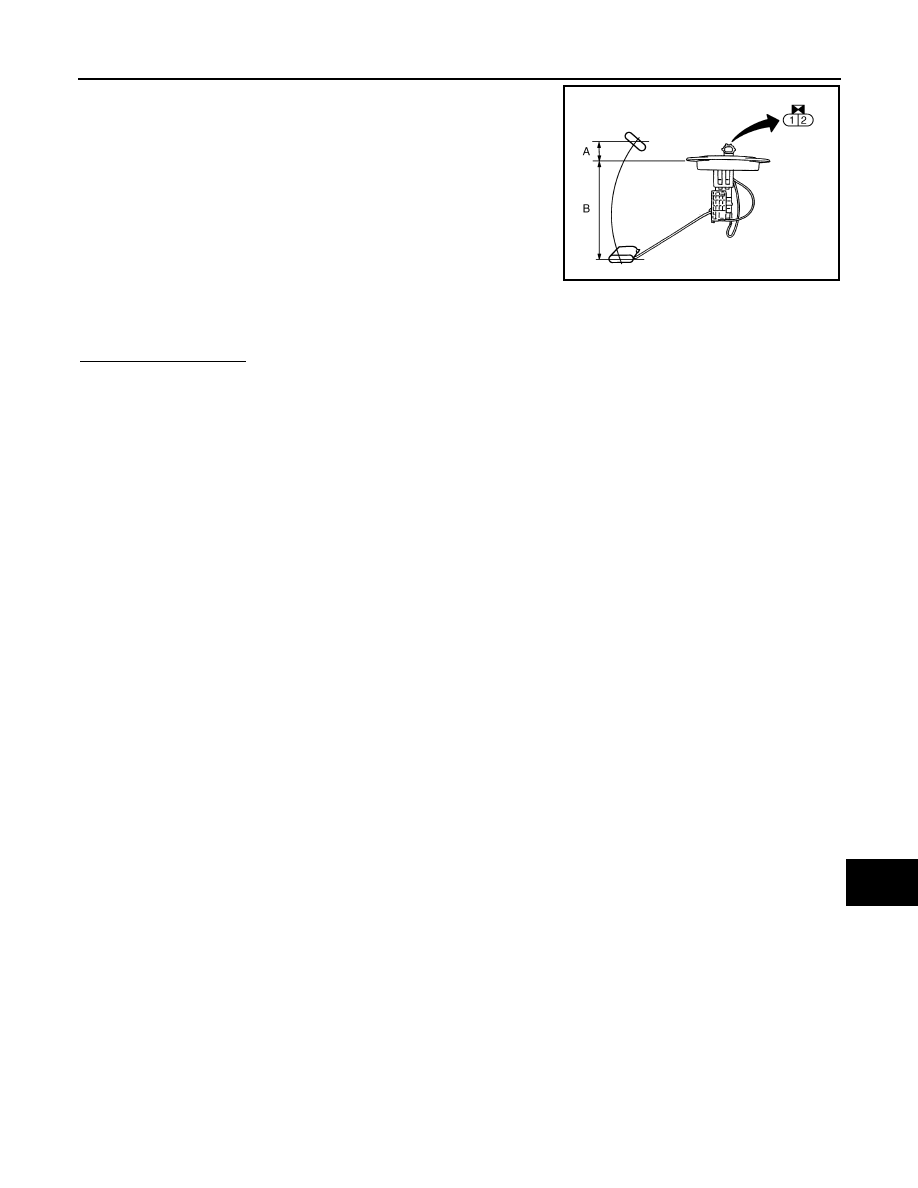

Inspect the resistance of fuel level sensor unit (sub).

Standard float position

Is inspection result OK?

YES

>> INSPECTION END

NO

>> Replace fuel level sensor unit (sub).

1 - 2

Full

: Approx. 3

Ω

Empty

: Approx. 43

Ω

JSNIA0111ZZ

Full (A) [mm (in)]

: Approx. 9 (0.35)

Empty (B) [mm (in)]

: Approx. 179 (7.05)