Infiniti G35 (V35) Sedan. Manual - part 744

HA-10

< FUNCTION DIAGNOSIS >

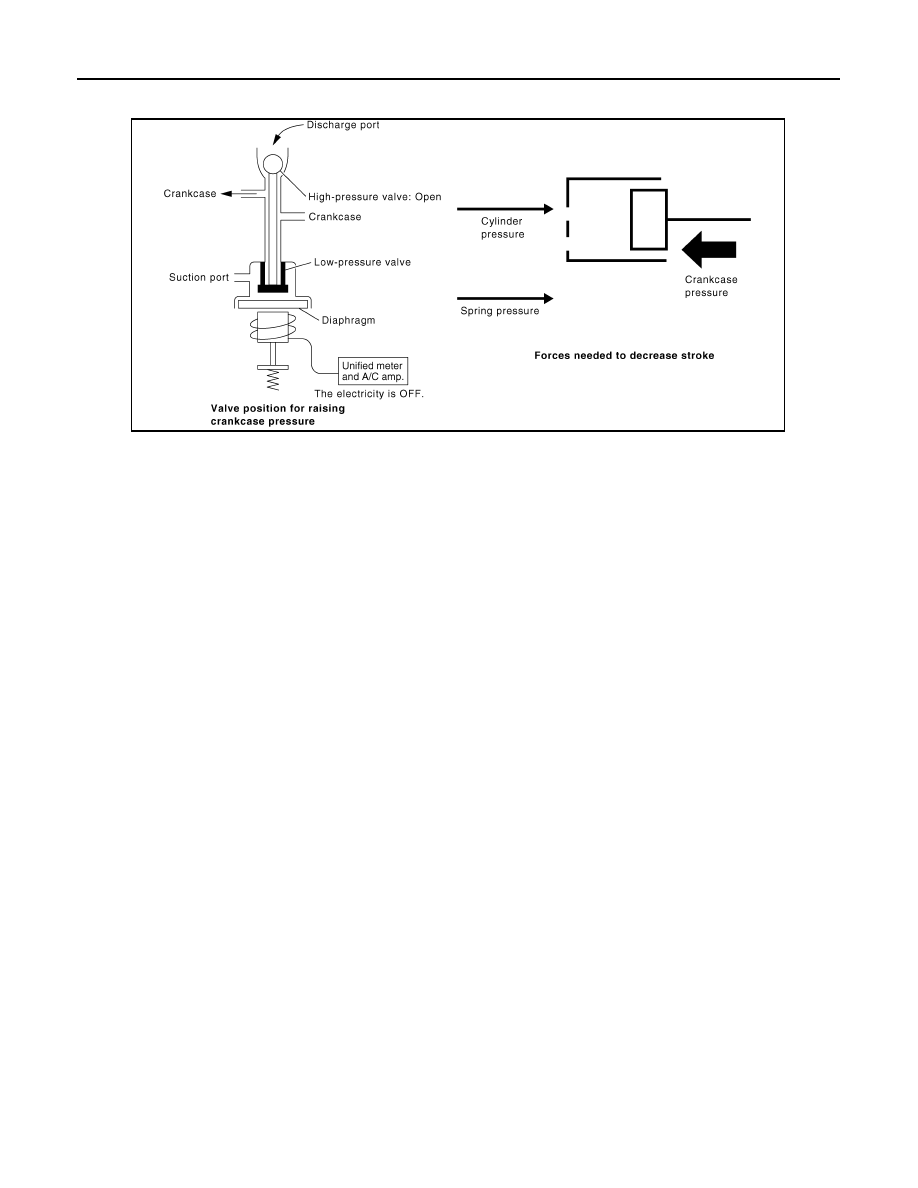

VARIABLE DISPLACEMENT COMPRESSOR SYSTEM

and also the piston stroke decrease. In other words, crankcase pressure increase triggers pressure differ-

ence between the piston and the crankcase. The pressure difference changes the angle of the swash plate.

SJIA0548E