Infiniti G35 (V35) Sedan. Manual - part 538

EC-298

< COMPONENT DIAGNOSIS >

[VQ35HR]

P0451 EVAP CONTROL SYSTEM PRESSURE SENSOR

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Replace malfunctioning component.

6.

CHECK APP SENSOR

EC-427, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> GO TO 7.

7.

REPLACE ACCELERATOR PEDAL ASSEMBLY

1.

Replace accelerator pedal assembly

2.

Go to

EC-427, "Special Repair Requirement"

.

>> INSPECTION END

8.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-298, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Replace EVAP control system pressure sensor.

9.

CHECK INTERMITTENT INCIDENT

GI-39, "Intermittent Incident"

>> INSPECTION END

Component Inspection

INFOID:0000000000956678

1.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

1.

Turn ignition switch OFF.

2.

Remove EVAP control system pressure sensor with its harness connector connected from EVAP canister.

Always replace O-ring with a new one.

3.

Install a vacuum pump to EVAP control system pressure sensor.

4.

Turn ignition switch ON and check output voltage between ECM harness connector and ground under the

following conditions.

CAUTION:

• Always calibrate the vacuum pump gauge when using it.

• Do not apply below -93.3 kPa (-0.952 kg/cm

2

, -13.53 psi) or pressure over 101.3 kPa (1.033 kg/

cm

2

, 14.69 psi).

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace EVAP control system pressure sensor

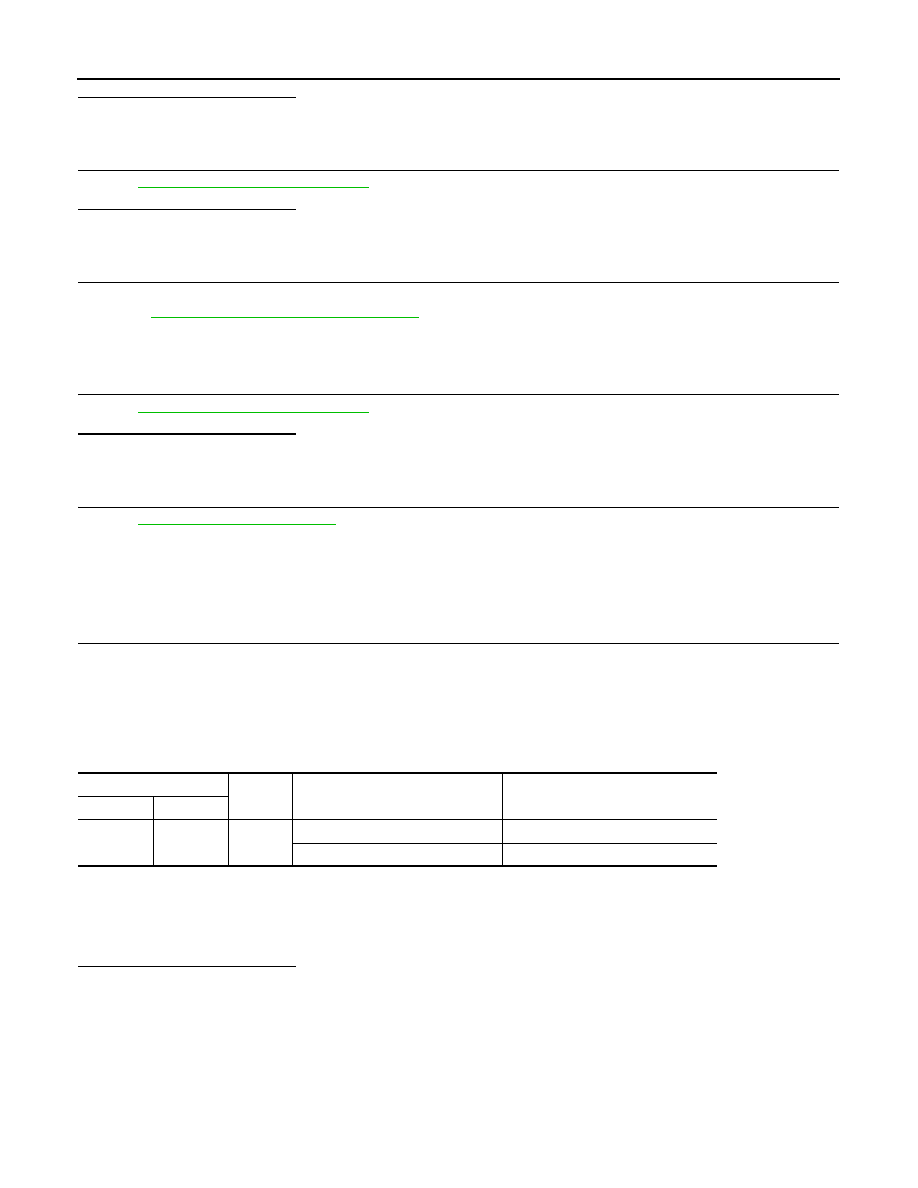

ECM

Ground

Condition

[Applied vacuum kPa (kg/cm

2

, psi)]

Voltage

Connector

Terminal

M107

102

Ground

Not applied

1.8 - 4.8V

-26.7 (-0.272, -3.87)

2.1 to 2.5V lower than above value