Infiniti G35 (V35) Sedan. Manual - part 528

EC-258

< COMPONENT DIAGNOSIS >

[VQ35HR]

P0340, P0345 CMP SENSOR (PHASE)

P0340, P0345 CMP SENSOR (PHASE)

Description

INFOID:0000000000956646

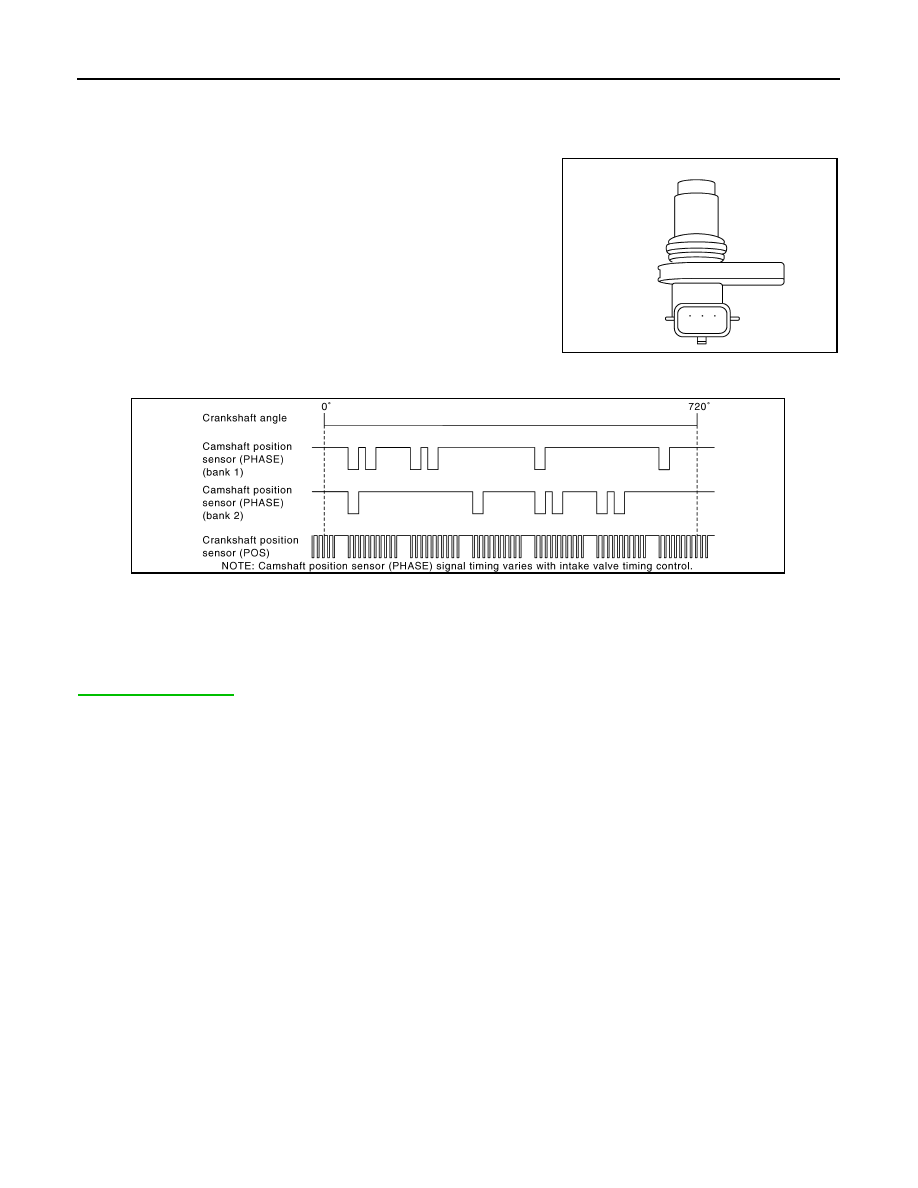

The camshaft position sensor (PHASE) senses the retraction of

camshaft (INT) to identify a particular cylinder. The camshaft position

sensor (PHASE) senses the piston position.

When the crankshaft position sensor (POS) system becomes inoper-

ative, the camshaft position sensor (PHASE) provides various con-

trols of engine parts instead, utilizing timing of cylinder identification

signals.

The sensor consists of a permanent magnet and Hall IC.

When engine is running, the high and low parts of the teeth cause

the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to

change.

Due to the changing magnetic field, the voltage from the sensor changes.

ECM receives the signals as shown in the figure.

DTC Logic

INFOID:0000000000956647

DTC DETECTION LOGIC

NOTE:

If DTC P0340 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643. Refer to

JMBIA0064ZZ

JMBIA0001GB