Infiniti G35 (V35) Sedan. Manual - part 504

EC-162

< COMPONENT DIAGNOSIS >

[VQ35HR]

P0101, P010B MAF SENSOR

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> GO TO 5.

5.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E106, M6

• Harness connectors M116, F103

• Harness for open or short between mass air flow sensor and ECM

• Harness for open or short between mass air flow sensor and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

6.

CHECK MAF SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between MAF sensor harness connector and ECM harness connector.

4.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

7.

CHECK MAF SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Check the continuity between MAF sensor harness connector and ECM harness connector.

2.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

8.

CHECK INTAKE AIR TEMPERATURE SENSOR

Check intake air temperature sensor (bank 1).

Refer to

EC-172, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Replace mass air flow sensor (bank 1) (with intake air temperature sensor).

9.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-298, "Component Inspection"

DTC

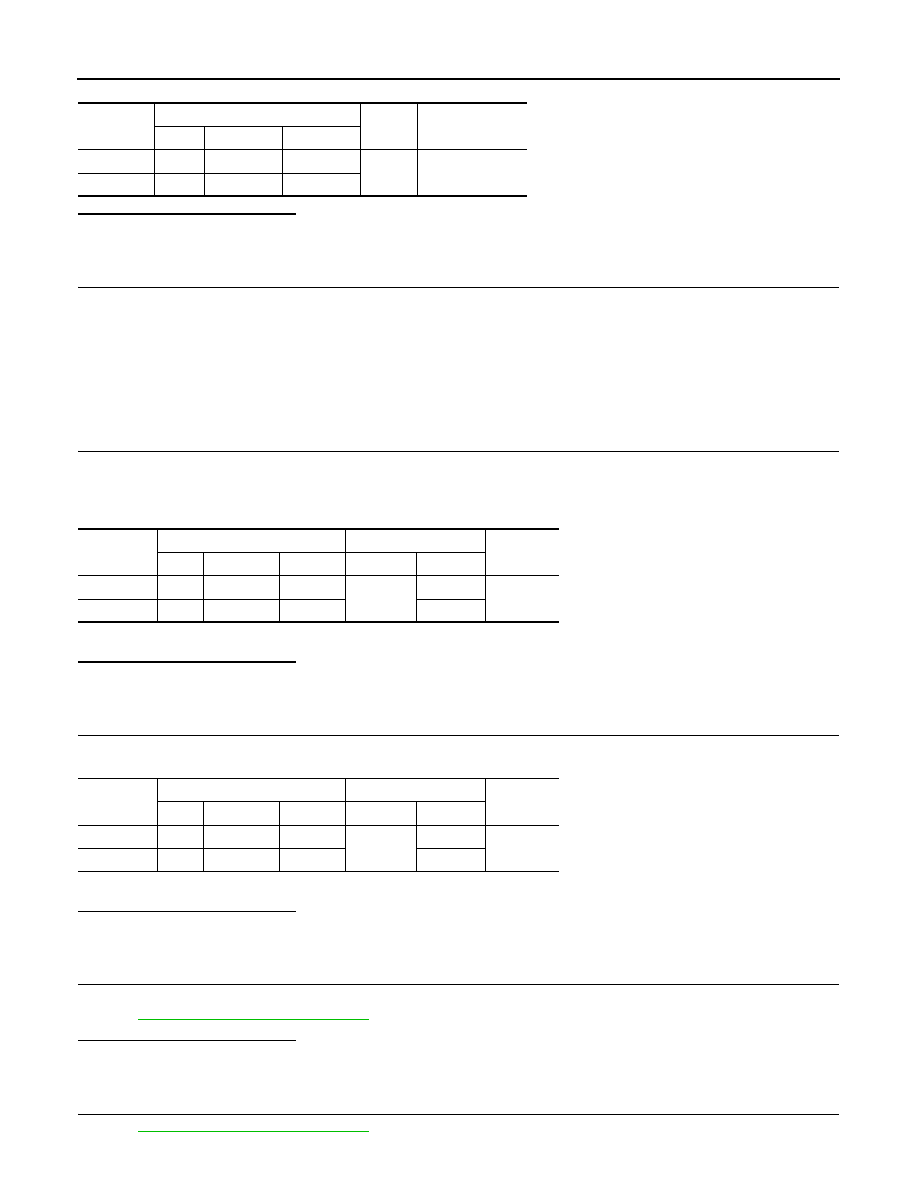

MAF sensor

Ground

Voltage

Bank

Connector

Terminal

P0101

1

F31

5

Ground

Battery voltage

P010B

2

F42

5

DTC

MAF sensor

ECM

Continuity

Bank

Connector

Terminal

Connector

Terminal

P0101

1

F31

4

F102

68

Existed

P010B

2

F42

4

94

DTC

MAF sensor

ECM

Continuity

Bank

Connector

Terminal

Connector

Terminal

P0101

1

F31

3

F102

77

Existed

P010B

2

F42

3

79