Infiniti G35 (V35) Sedan. Manual - part 460

DLN-274

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R200V]

DRIVE PINION

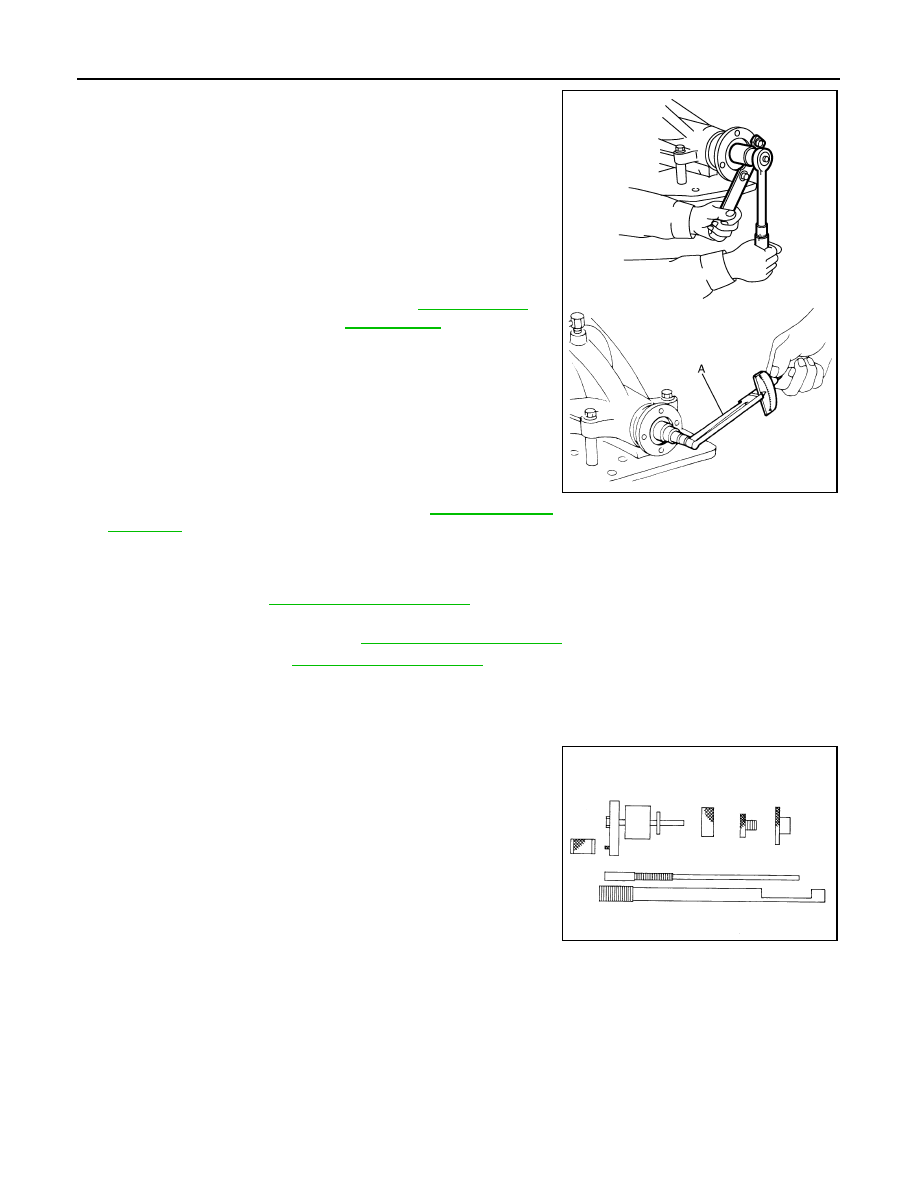

10. Apply anti-corrosion oil to the thread and seat of drive pinion

lock nut, and temporarily tighten drive pinion lock nut to drive

pinion.

CAUTION:

Never reuse drive pinion lock nut.

11. Adjust to the drive pinion lock nut tightening torque and pinion

bearing preload torque.

CAUTION:

• Adjust to the lower limit of the drive pinion lock nut tight-

ening torque first.

• If the preload torque exceeds the specified value, replace

collapsible spacer and tighten it again to adjust. Never

loosen drive pinion lock nut to adjust the preload torque.

• After adjustment, rotate drive pinion back and forth 2 to 3

times to check for unusual noise, rotation malfunction,

and other malfunctions.

12. Install differential case assembly. Refer to

CAUTION:

Never install rear cover yet.

13. Check and adjust drive gear runout, tooth contact, drive gear to drive pinion backlash, and companion

flange runout. Refer to

Recheck above items. Readjust the above description, if necessary.

14. Check total preload torque. Refer to

.

15. Install rear cover. Refer to

M/T : Adjustment

INFOID:0000000000957455

PINION GEAR HEIGHT

1.

Make sure all parts are clean and that the bearings are well

lubricated.

2.

Assemble the pinion gear bearings into the differential shim

selector tool [SST:

—

(J-34309)].

A: Preload gauge [SST: ST3127S000 (J-25765-A)]

Standard

Pinion bearing preload

: Refer to

JSDIA0047ZZ

SPD769