Infiniti G35 (V35) Sedan. Manual - part 455

DLN-254

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R200V]

DIFFERENTIAL ASSEMBLY

SIDE BEARING PRELOAD

• Before inspection and adjustment, drain gear oil.

1.

Remove rear cover. Refer to

.

2.

Make sure all parts are clean. Also, make sure the bearings are

well lubricated with gear oil.

3.

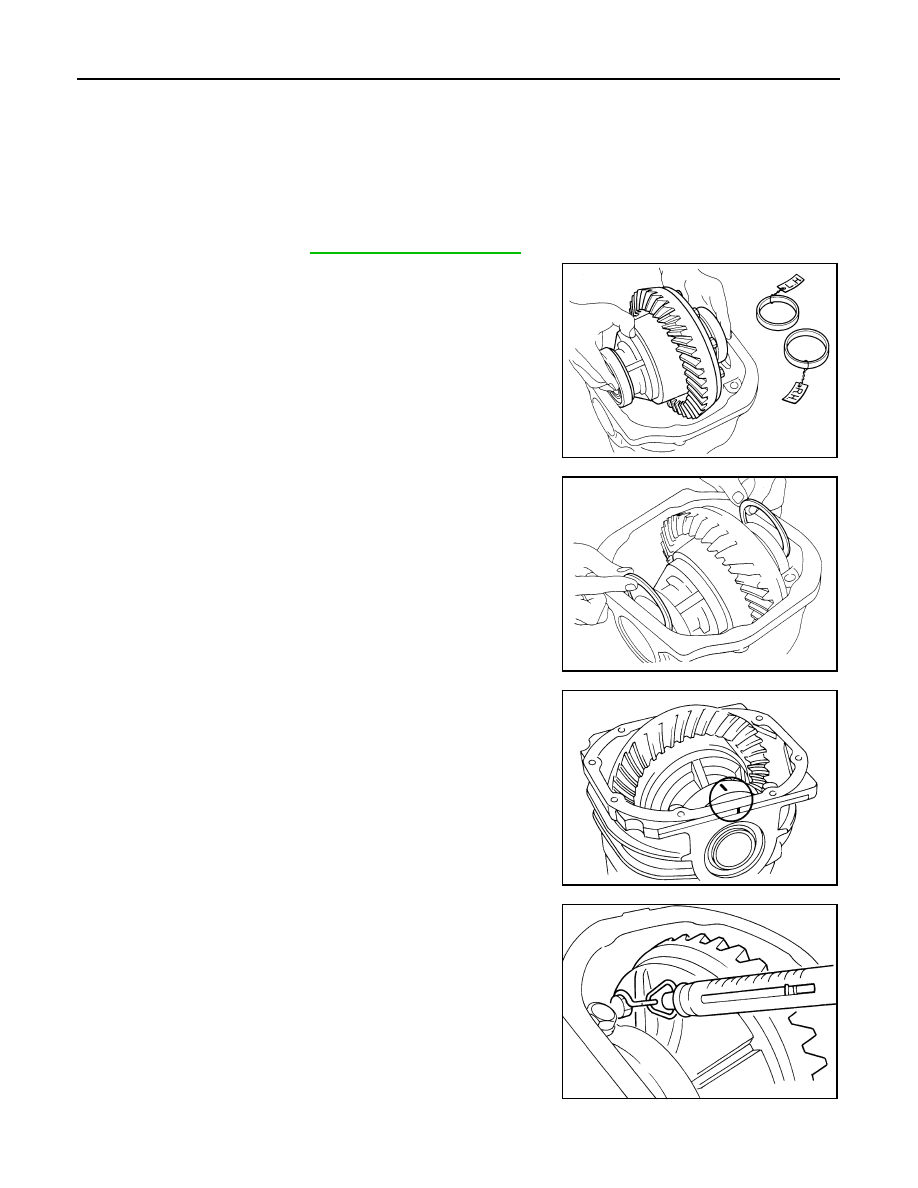

Place the differential case, with side bearings and bearing races

installed, into gear carrier.

4.

Insert left and right original side bearing adjusting washers in

place between side bearings and gear carrier.

5.

Install bearing caps in their correct locations and tighten bearing

cap mounting bolts.

6.

Turn the carrier several times to seat the bearings.

7.

Measure the turning torque of the carrier at the drive gear

mounting bolts with a spring gauge [SST:

—

(J-8129)].

When the preload is small

On pinion bearings:

Tighten the drive pinion lock nut.

On side bearings:

Use thicker side bearing adjusting washers by the same amount to

each side.

SPD919

SPD924

PDIA0069E

Specification

: 34.2 – 39.2 N (3.5 – 4.0 kg,

7.7 – 8.8 lb) of pulling force

at the drive gear bolt

SPD194A