Infiniti G35 (V35) Sedan. Manual - part 441

DLN-198

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R200]

DIFFERENTIAL ASSEMBLY

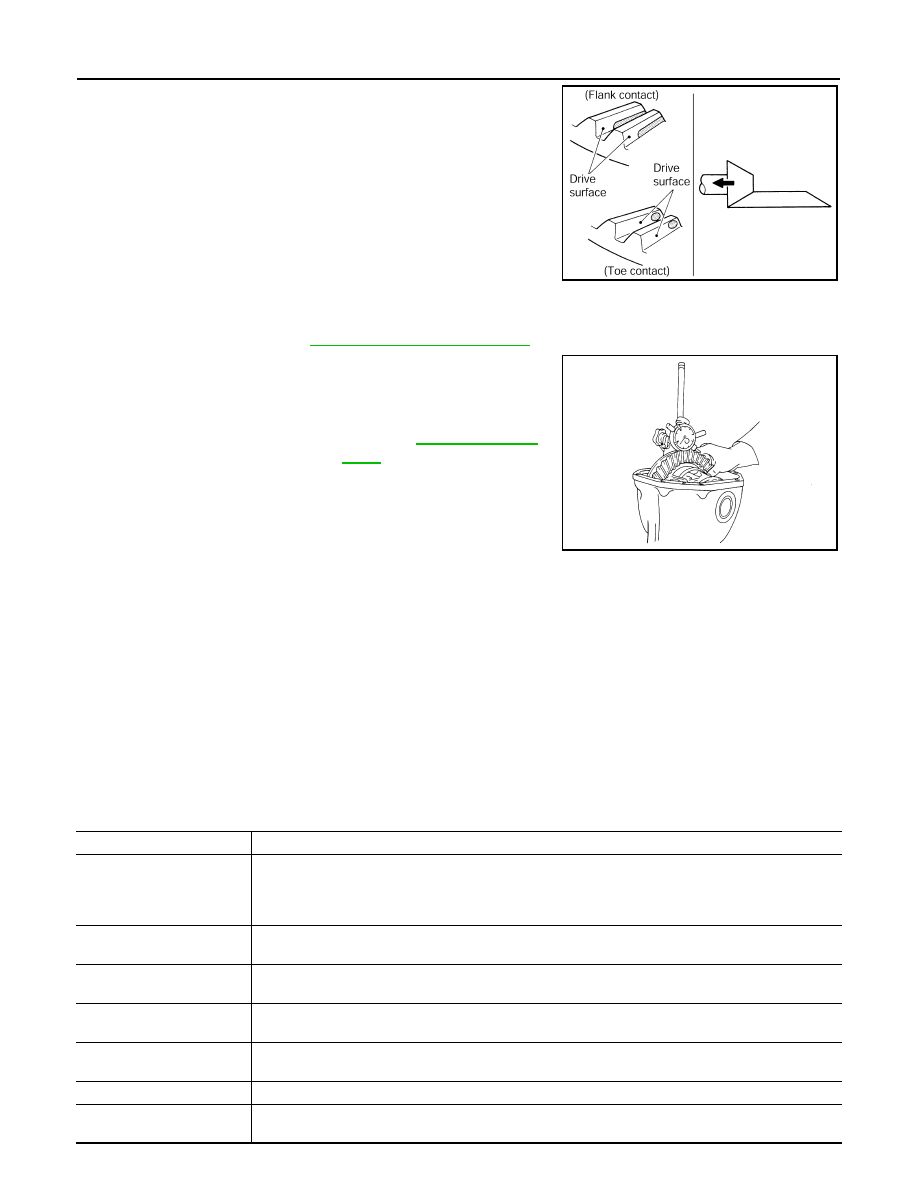

• If the tooth contact is near the flank (flank contact), or near the

toe (toe contact), thin pinion height adjusting washers to move

drive pinion farther from drive gear.

BACKLASH

• Before inspection and adjustment, drain gear oil.

1.

Remove rear cover. Refer to

.

2.

Fit a dial indicator to the drive gear face to measure the back-

lash.

• If the backlash is outside of the specified value, change the

thickness of side bearing adjusting washer.

CAUTION:

Never change the total amount of washers as it will change the bearing preload.

AWD : Inspection After Disassembly

INFOID:0000000000957404

Clean up the disassembled parts. Then, inspect if the parts are worn or damaged. If so, follow the measures

below.

PDIA0441E

Standard

Backlash

: Refer to

.

When the backlash is large:

Make drive gear back side adjusting washer thicker,

and drive gear tooth side adjusting washer thinner by

the same amount.

When the backlash is small:

Make drive gear back side adjusting washer thinner,

and drive gear tooth side adjusting washer thicker by

the same amount.

SPD513

Content

Conditions and Measures

Hypoid gear

• If the gear teeth do not mesh or line-up correctly, determine the cause and adjust or replace as nec-

essary.

• If the gears are worn, cracked, damaged, pitted or chipped (by friction) noticeably, replace with new

drive gear and drive pinion as a set.

Bearing

• If any chipped (by friction), pitted, worn, rusted or scratched mark, or unusual noise from the bearing

is observed, replace as a bearing assembly (as a new set).

Side gear and Pinion mate

gear

• If any cracks or damage on the surface of the tooth is found, replace.

• If any worn or chipped mark on the contact sides of the thrust washer is found, replace.

Side gear thrust washer and

pinion mate thrust washer

• If it is chipped (by friction), damaged, or unusually worn, replace.

Oil seal

• Whenever disassembled, replace.

• If wear, deterioration of adherence (sealing force lips), or damage is detected on the lips, replace them.

Differential case

• If any wear or crack on the contact sides of the differential case is found, replace.

Companion flange

• If any chipped mark (about 0.1 mm, 0.004 in) or other damage on the contact sides of the lips of the

companion flange is found, replace.