Infiniti G35 (V35) Sedan. Manual - part 423

DLN-126

< DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: F160A]

DIFFERENTIAL ASSEMBLY

1.

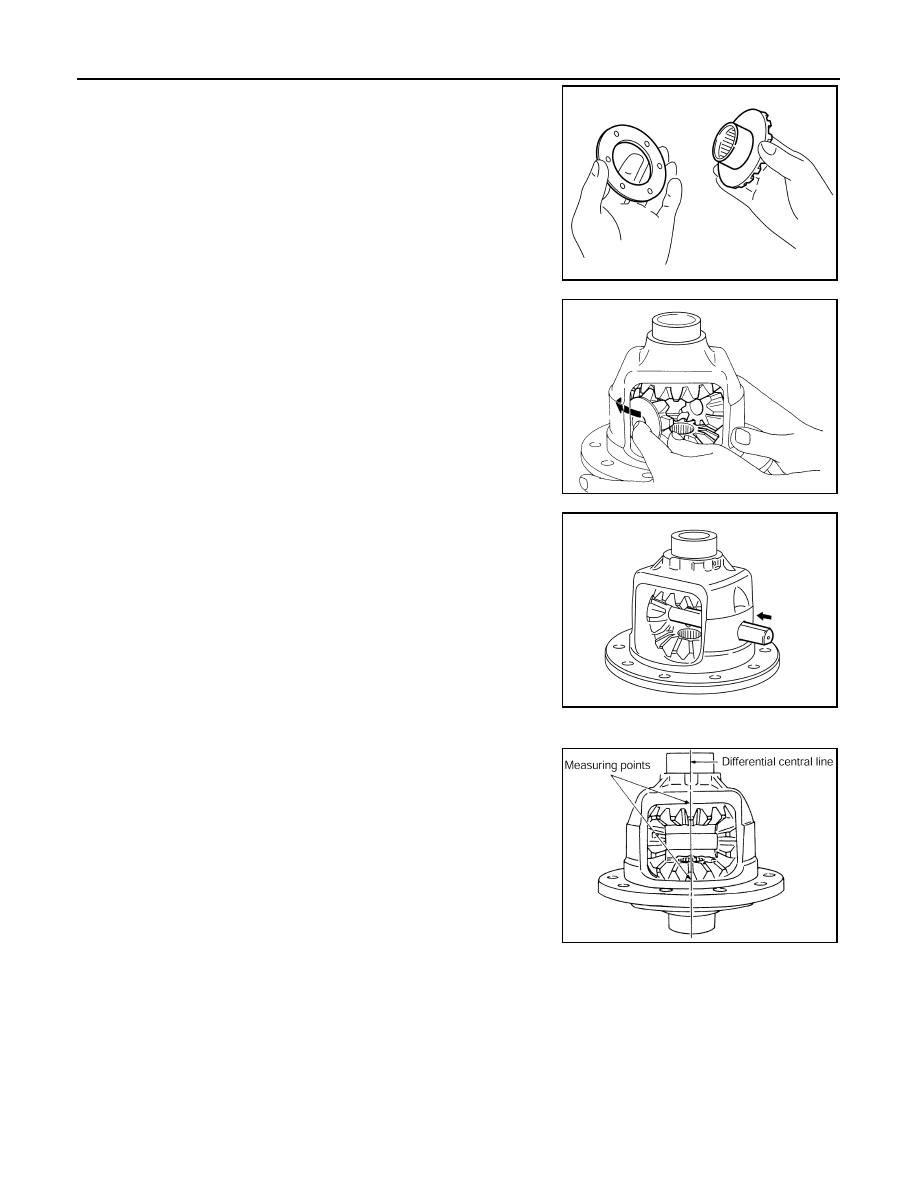

Install side gear thrust washers with the same thickness as the

ones installed prior to disassembly or reinstall the old ones on

the side gears.

2.

Install side gears and thrust washers into differential case.

CAUTION:

• Never reuse circular clip.

• Make sure that the circular clip is installed to side gear

(side retainer side).

3.

Align 2 pinion mate gears in diagonally opposite positions, then

rotate and install them into differential case after installing thrust

washer to pinion mate gear.

4.

Align the lock pin holes on differential case with shaft, and install

pinion mate shaft.

5.

Measure side gear end play. If necessary, select the appropriate side gear thrust washers.

a.

Place differential case straight up so that side gear to be mea-

sured comes upward.

SDIA0193J

SDIA2025E

SDIA0195J

PDIA0460E