Content .. 1352 1353 1354 1355 ..

Infiniti G35 (V35) Sedan. Manual - part 1354

TM-108

< FUNCTION DIAGNOSIS >

[5AT: RE5R05A]

SHIFT LOCK SYSTEM

SHIFT LOCK SYSTEM

System Description

INFOID:0000000000957005

The selector lever cannot shifted from the “P” position unless the brake pedal is depressed while the ignition

switch ON.

The shift lock is unlocked by the shift lock unit that is activated when the ignition switch ON and the stop lamp

switch is turned ON (brake pedal is depressed).

Therefore, the shift lock unit receives no ON signal and the shift lock remains locked if the above conditions

are not fulfilled. (However, a shift operation is allowed if the shift lock release button is pressed.)

SHIFT LOCK OPERATION AT “P” POSITION

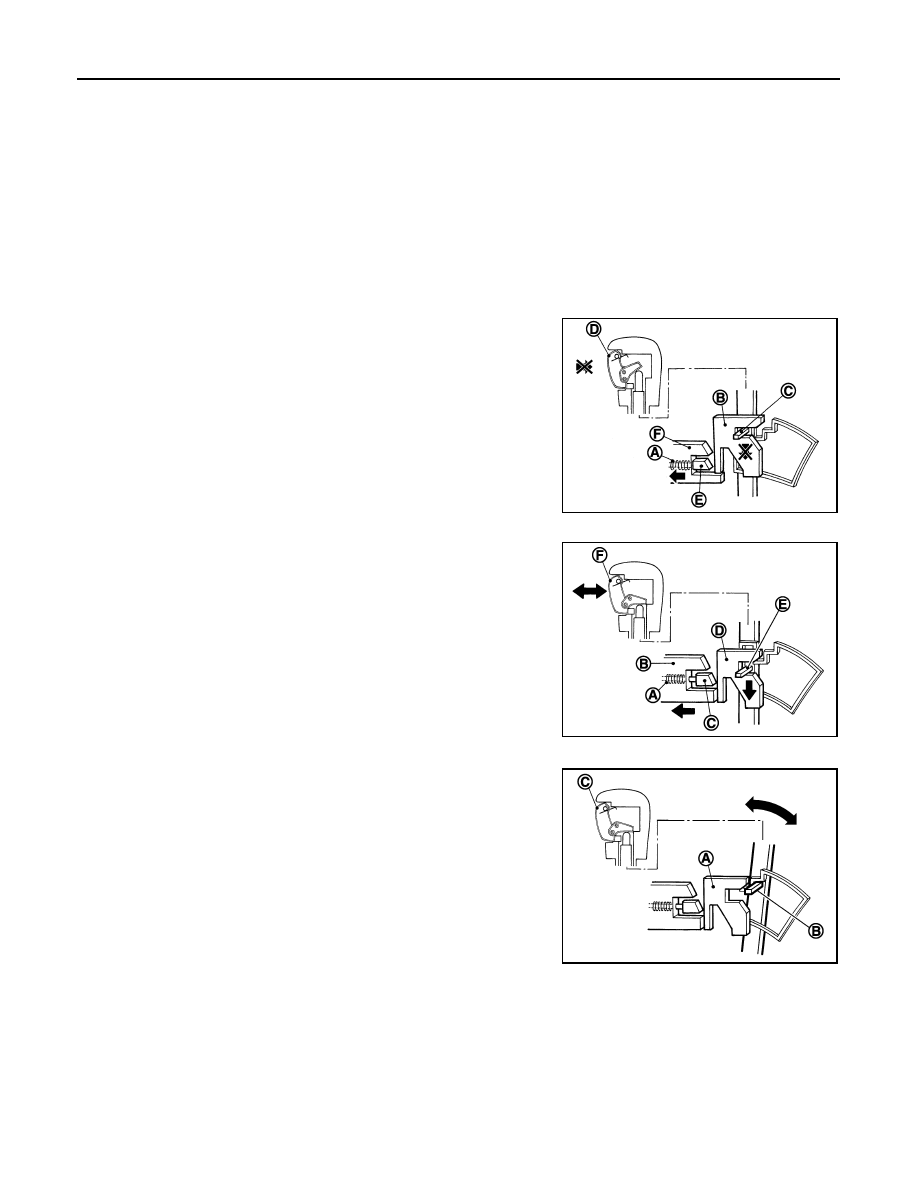

When Brake Pedal Is Not Depressed (No Shift Operation Allowed)

The shift lock solenoid (A) inside the shift lock unit is not energized if

the brake pedal is not depressed while the ignition switch ON.

The lock plate (B) lowers according to the downward movement of

the position pin (C) when the selector button (D) is pressed, and

presses only slider B (E) into the shift lock unit. Slider A (F) located

below the lock plate prevents the downward movement of the lock

plate with the spring force. The selector lever cannot be shifted from

the “P” position for this reason.

However, slider A is forcibly pressed into the shift lock unit, allowing

the selector lever to shift if the shift lock release button is pressed.

When Brake Pedal Is Depressed (Shift Operation Allowed)

The shift lock solenoid (A) inside the shift lock unit is energized and

the relative positions of sliders A (B) and B (C) are maintained when

the brake pedal is depressed while the ignition switch ON.

The lock plate (D) lowers according to the downward movement of

the position pin (E), thrusting away sliders A and B, when the selec-

tor button (F) is pressed.

The position pin lowers to the position that allows shift operation for

this reason. As a result, the selector lever can be shifted out of the P

position.

OPERATION AT OTEHER THAN “P” POSITION

The shift lock function will not operate at any position other than “P”

because the lock plate (A) is only set for the “P” position. Accord-

ingly, the selector lever can be shifted to any position regardless of

the brake operation.

The position pin (B) enters the “P” position thrusting away the lock

plate when the selector lever is shifted to the “P” position. Then, the

shift mechanism is locked when the selector button (C) is released.

“P” POSITION RETAINING MECHANISM (IGNITION SWITCH LOCK)

When ignition switch is not in the ON position, power is not applied to the shift lock solenoid in the shift lock

unit. This causes shift lock state, and then “P” position is retained.

When an actuating system in the shift lock unit has a malfunction, selector lever is unable to operate from the

“P” position even when pressing the brake pedal with the ignition switch ON. However, when pressing the shift

lock release button, slider A is forcibly pressed into the shift lock unit. This allows shift lock to be released and

selector lever enables the select operation from the “P” position.

CAUTION:

Do not use the shift lock release button except when the select lever is inoperative even when press-

ing the brake pedal with the ignition switch ON.

JSDIA0119ZZ

JSDIA0120ZZ

JSDIA0121ZZ