Content .. 1344 1345 1346 1347 ..

Infiniti G35 (V35) Sedan. Manual - part 1346

TM-76

< SERVICE DATA AND SPECIFICATIONS (SDS)

[6MT: FS6R31A]

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

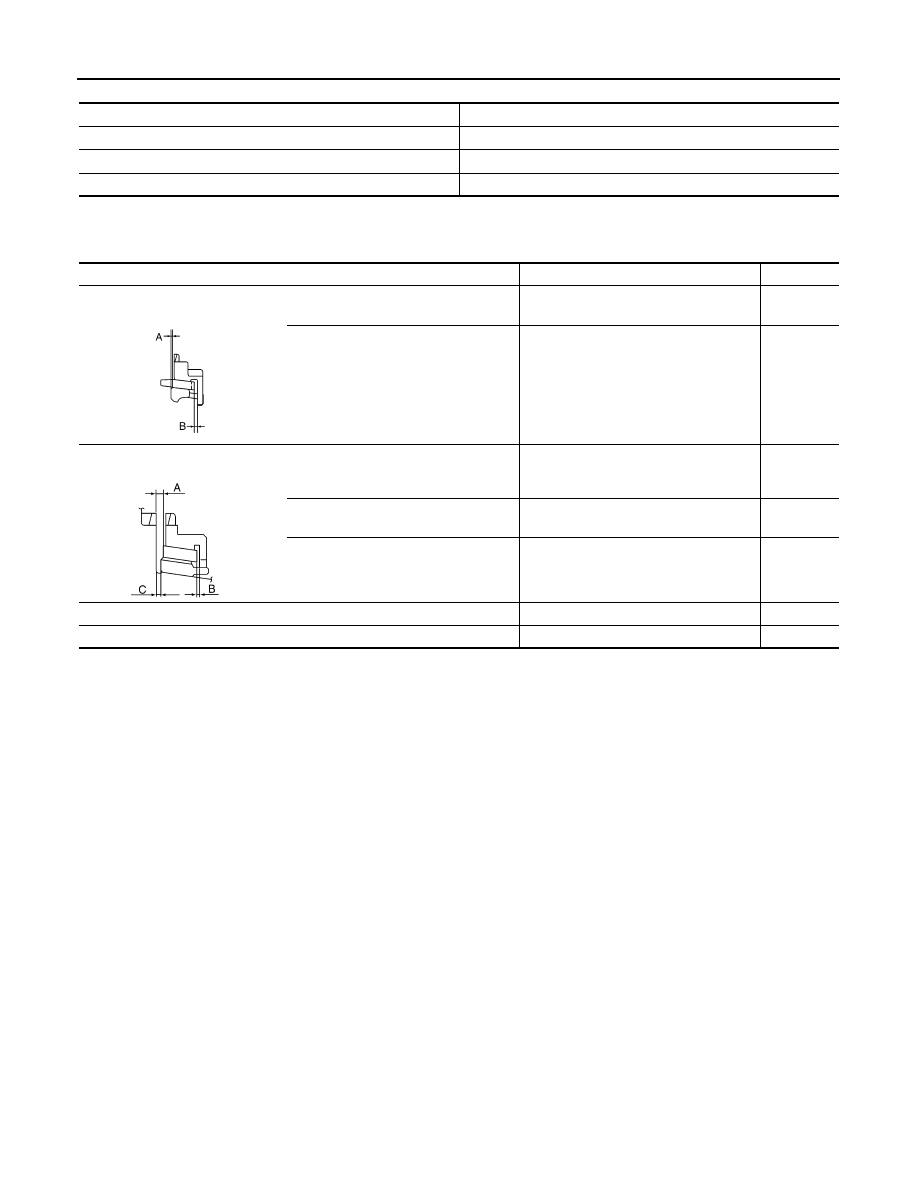

Baulk Ring Clearance

INFOID:0000000000956993

Unit: mm (in)

Item

Standard value

Counter shaft

0 - 0.10 (0 - 0.004)

Main drive gear

0 - 0.10 (0 - 0.004)

Mainshaft

0 - 0.10 (0 - 0.004)

Measurement point

Standard value

Limit value

4th

(Double-cone synchronizer)

Clearance between synchronizer cone

and inner baulk ring end face “A”

0.50 - 0.70 (0.020 - 0.028)

0.3 (0.012)

Clearance between outer baulk ring

pawl and synchronizer cone “B”

0.85 - 1.35 (0.033 -0.053)

0.7 (0.028)

1st, 2nd, and 3rd

(Triple-cone synchronizer)

Clearance between synchronizer cone

and clutch gear end face “A”

1st: 0.65 - 1.25 (0.026 - 0.049)

2nd: 0.60 - 1.30 (0.024 - 0.051)

3rd: 0.60 - 1.30 (0.024 - 0.051)

0.3 (0.012)

0.3 (0.012)

0.3 (0.012)

Clearance between outer baulk ring

pawl and synchronizer cone “B”

0.85 - 1.35 (0.033 - 0.053)

0.7 (0.028)

Clearance between inner baulk ring

and clutch gear end face “C”

1st: 0.80 - 1.2 (0.031 - 0.047)

2nd: 0.75 - 1.25 (0.030 - 0.049)

3rd: 0.75 - 1.25 (0.030 - 0.049)

0.3 (0.012)

0.3 (0.012)

0.3 (0.012)

5th and 6th

0.70 - 1.35 (0.028 - 0.053)

0.5 (0.020)

Reverse

0.75 - 1.20 (0.030 - 0.047)

0.5 (0.020)

PCIB0249E

PCIB0835J