Content .. 1271 1272 1273 1274 ..

Infiniti G35 (V35) Sedan. Manual - part 1273

ST-42

< ON-VEHICLE REPAIR >

STEERING GEAR AND LINKAGE

e.

Bent cut end of the wire toward rack axial as shown in the figure

after twisting the wire 4 to 4.5 turns so that cut end does not con-

tact with boot.

CAUTION:

Keep gap from cylinder tube 5 mm (0.20 in) or more.

19. Install cylinder tubes to gear housing assembly.

20. Install low pressure piping.

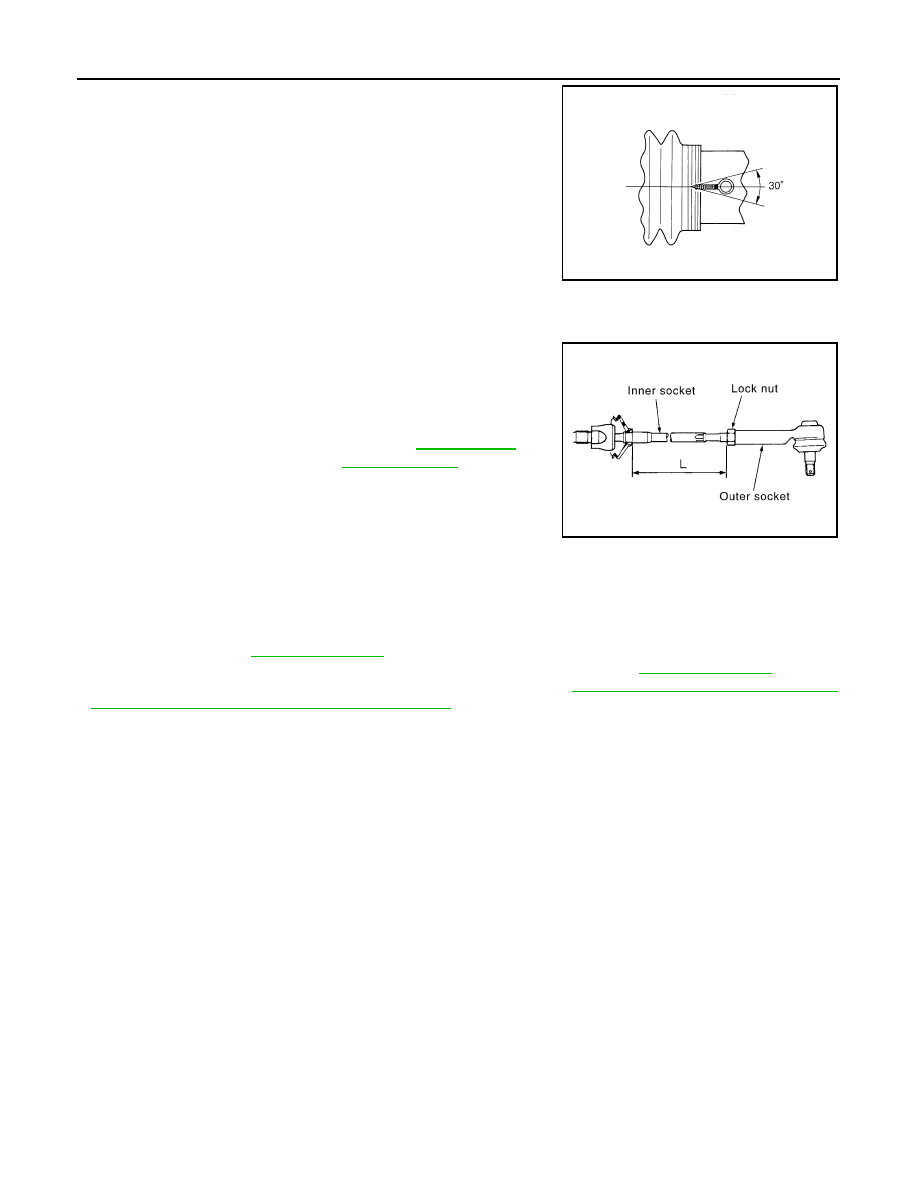

21. Adjust inner socket to standard length “L”, and then tighten lock

nut to the specified torque. Check length “L” again after tighten-

ing lock nut.

CAUTION:

Adjust toe-in after this procedure. Length achieved after

toe-in adjustment is not necessary the above value.

AWD : Inspection

INFOID:0000000000958681

INSPECTION AFTER INSTALLATION

• Check if steering wheel turns smoothly when it is turned several times fully to the end of the left and right.

• Check the steering wheel play, neutral position steering wheel, steering wheel turning force, and front wheel

turning angle. Refer to

.

• Check the fluid level, fluid leakage, and air bleeding hydraulic system. Refer to

.

• Perform 4WAS front actuator neutral position adjustment. Refer to

NEUTRAL POSITION ADJUSTMENT : Description"

INSPECTION AFTER DISASSEMBLY

Boot

• Check boot for cracks, and replace it if a malfunction is detected.

Rack Assembly

• Check rack for damage or wear, and replace it if a malfunction is detected.

Gear-Sub Assembly

• Check gear-sub assembly for damage or wear, and replace it if a malfunction is detected.

• Rotate gear-sub assembly and check for torque variation or rattle, and replace it if a malfunction is detected.

Gear Housing Assembly

• Check gear housing assembly for damage and scratches (inner wall). Replace if there are.

Outer Socket and Inner Socket

• Check the following items and replace the component if it does not meet the standard.

BALL JOINT SWINGING TORQUE

STC0124D

Standard

Inner socket length “L”

: Refer to

.

SGIA0167E