Content .. 1074 1075 1076 1077 ..

Infiniti G35 (V35) Sedan. Manual - part 1076

PWC-136

< COMPONENT DIAGNOSIS >

[FRONT WINDOW ANTI-PINCH]

POWER SUPPLY AND GROUND CIRCUIT

COMPONENT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

POWER WINDOW MAIN SWITCH

POWER WINDOW MAIN SWITCH : Description

INFOID:0000000000961658

• BCM supplies power.

• It operates each power window motor via corresponding power window switch and makes window move up/

down when power window main switch is operated.

POWER WINDOW MAIN SWITCH : Component Function Check

INFOID:0000000000961659

Power Window Main Switch

1.

CHECK POWER WINDOW MAIN SWITCH FUNCTION

Does power window motor operate with power window main switch operation?

Is the inspection result normal?

YES

>> Power window main switch power supply and ground circuit are OK.

NO

>> Refer to

PWC-136, "POWER WINDOW MAIN SWITCH : Diagnosis Procedure"

POWER WINDOW MAIN SWITCH : Diagnosis Procedure

INFOID:0000000000961660

Power Window Main Switch Power Supply Circuit Check

1.

CHECK POWER SUPPLY CIRCUIT

1.

Turn ignition switch ON.

2.

Check voltage between power window main switch connector and ground.

Is the measurement value within the specification?

YES

>> GO TO 3.

NO

>> GO TO 2.

2.

CHECK HARNESS CONTINUITY

1.

Turn ignition switch OFF.

2.

Disconnect BCM connector and power window main switch connector.

3.

Check continuity between BCM connector and power window main switch connector.

4.

Check continuity between BCM connector and ground.

Is the inspection result normal?

YES

>> GO TO 4.

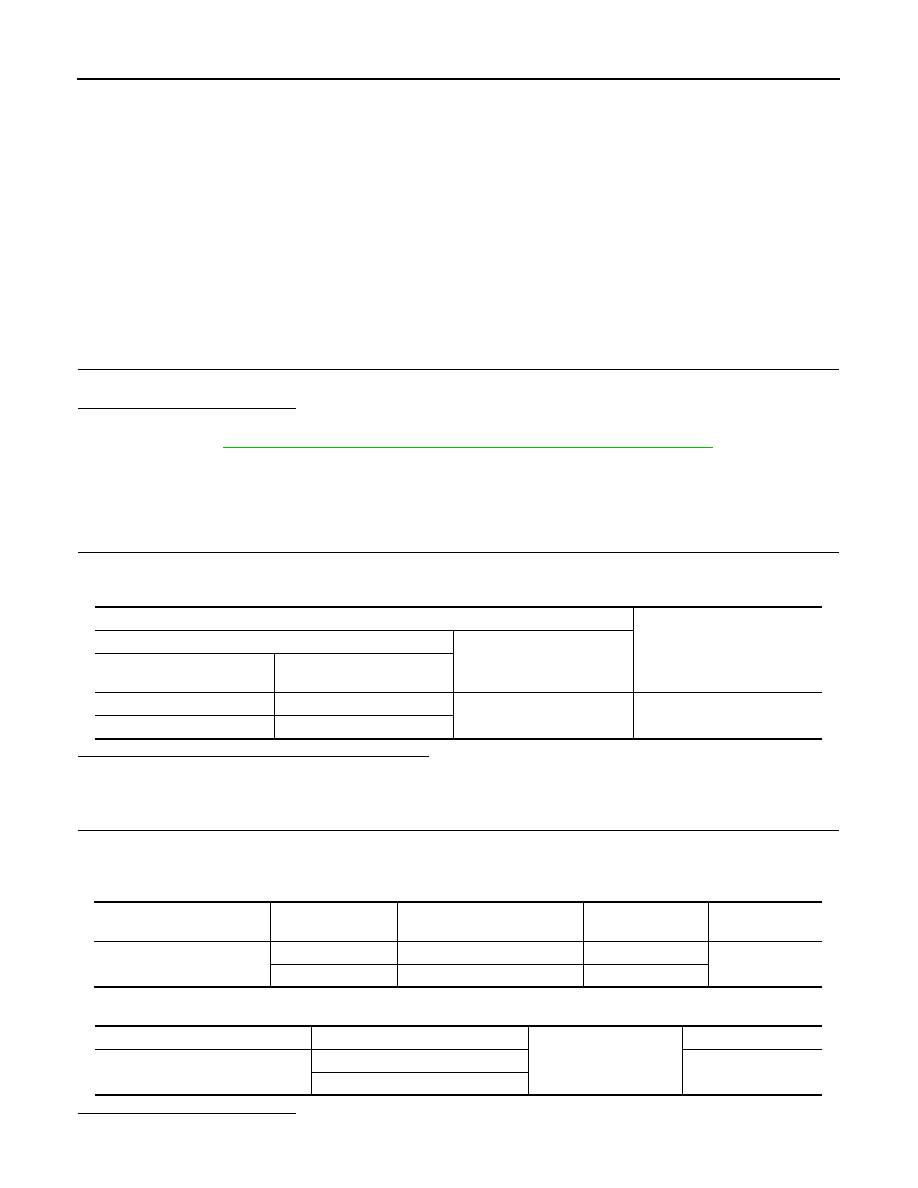

Terminal

Voltage (V)

(Approx.)

(+)

(–)

Power window main switch

connector

Terminal

D8

10

Ground

Battery voltage

D9

19

BCM connector

Terminal

Power window main switch

connector

Terminal

Continuity

M118

3

D8

10

Existed

2

D9

19

BCM connector

Terminal

Ground

Continuity

M118

3

Not existed

2