Infiniti G35 (V35) Sedan. Manual - part 18

ADP-66

< COMPONENT DIAGNOSIS >

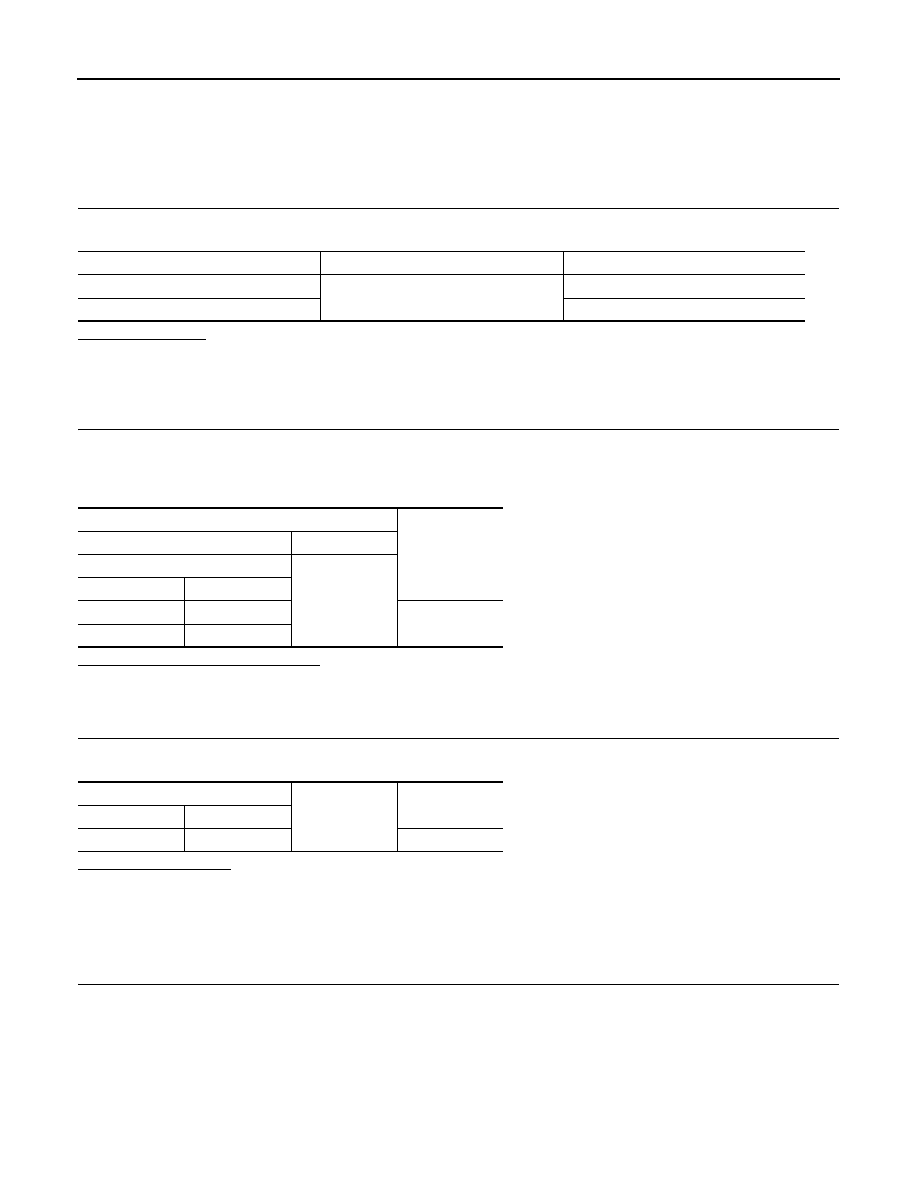

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis Procedure

INFOID:0000000000960646

1.

CHECK FUSE AND FUSIBLE LINK

Check that the following fuse and fusible link are not blown.

Is the fuse fusing?

YES

>> Replace the blown fuse or fusible link after repairing the affected circuit if a fuse or fusible link is

blown.

NO

>> GO TO 2.

2.

CHECK POWER SUPPLY CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect BCM connectors.

3.

Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES

>> GO TO 3.

NO

>> Repair harness or connector.

3.

CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES

>> INSPECTION END

NO

>> Repair harness or connector.

BCM : Special Repair Requirement

INFOID:0000000000960647

1.

REQUIRED WORK WHEN REPLACING BCM

Initialize IVIS by CONSULT-III. For the details of initialization refer to CONSULT-III operation manual NATS-

IVIS/NVIS.

>> Work end.

DRIVER SEAT CONTROL UNIT

DRIVER SEAT CONTROL UNIT : Diagnosis Procedure

INFOID:0000000000960648

Terminal No.

Signal name

Fuse and fusible link No.

1

Battery power supply

K

11

10

Terminals

Voltage

(Approx.)

(+)

(

−

)

BCM

Ground

Connector

Terminal

M118

1

Battery voltage

M119

11

BCM

Ground

Continuity

Connector

Terminal

M119

13

Existed