Infiniti FX35 / FX45. Manual - part 889

FRONT OIL SEAL

RFD-11

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

M

A

B

RFD

N

O

P

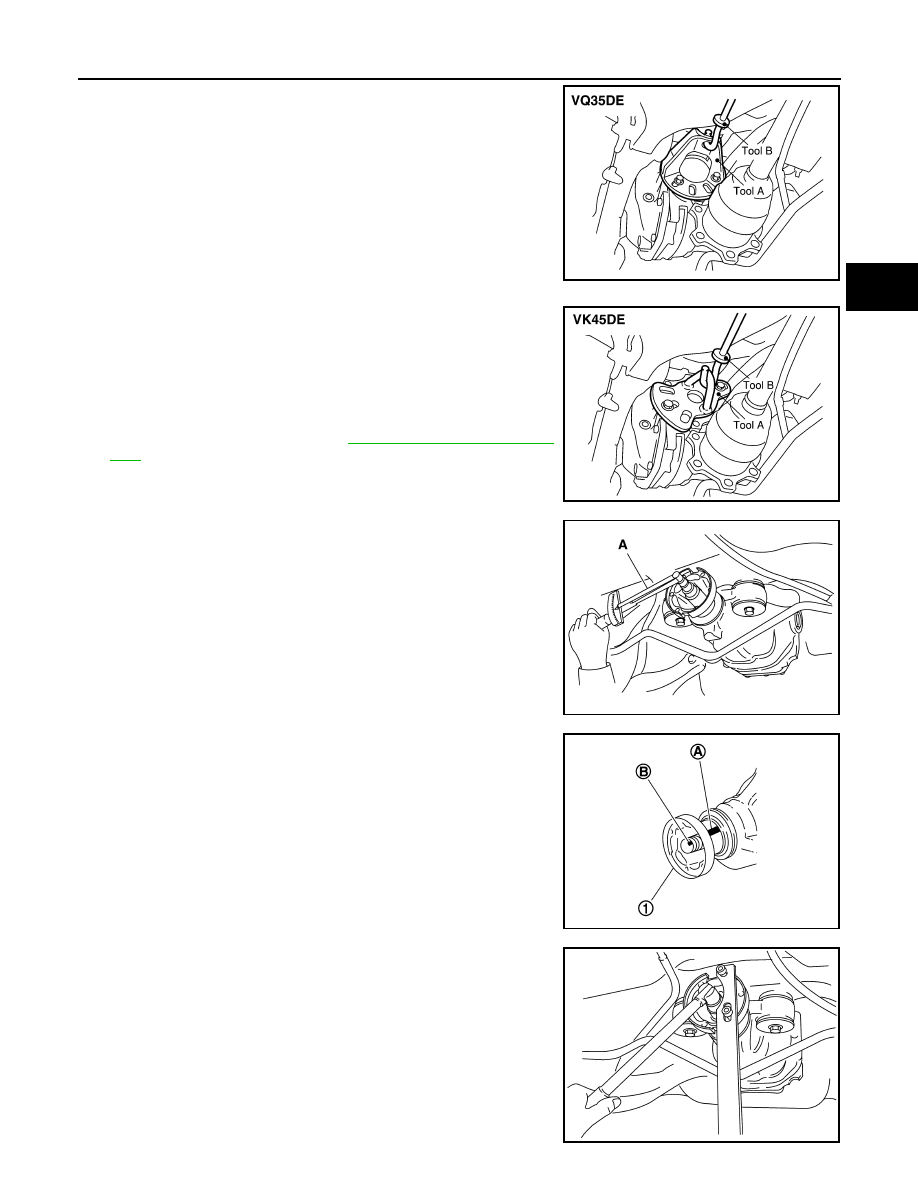

• For VQ35DE models

NOTE:

Circular clip installation position: Final drive side

• For VK45DE models

NOTE:

Circular clip installation position: Final drive side

7.

Remove propeller shaft. Refer to

8.

Measure the total preload with the preload gauge.

NOTE:

Record the preload measurement.

9.

Put matching mark (B) on the end of the drive pinion. The

matching mark (B) should be in line with the matching mark (A)

on companion flange (1).

CAUTION:

For matching mark, use paint. Never damage companion

flange and drive pinion.

NOTE:

The matching mark (A) on the final drive companion flange (1)

indicates the maximum vertical runout position.

10. Remove drive pinion lock nut using the flange wrench.

Tool number

A: KV40104100 (

—

)

B: ST36230000 (J-25840-A)

SDIA1582E

Tool number

A: KV40101000 (

—

)

B: ST36230000 (J-25840-A)

SDIA1583E

Tool number

A: ST3127S000 (J-25765-A)

PDIA0977E

PDIA0750J

PDIA0978E