Infiniti FX35 / FX45. Manual - part 877

REAR WHEEL HUB AND KNUCKLE

RAX-7

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

M

A

B

RAX

N

O

P

9.

Remove parking brake cable and parking brake shoe from back plate. Refer to

.

10. Remove fixing nuts of anchor block with power tool, then remove anchor block and back plate from axle.

11. Loosen fixing bolts and nuts of front lower link, radius rod, and rear lower link in side of suspension mem-

ber.

12. Set jack under rear lower link. Then remove fixing bolt in front lower link side of shock absorber with

power tool.

13. Remove bolt and nut in axle side of rear lower link with power tool. Then remove coil spring. Refer to

14. Remove fixing bolts and nuts in axle side of front lower link, radius rod with power tool.

15. Remove suspension arm and cotter pin at axle, then loosen mounting nut.

16. Use a ball joint remover (suitable tool) to remove suspension arm from axle. Be careful not to damage ball

joint boot.

CAUTION:

Tighten temporarily mounting nut to prevent damage to threads and to prevent ball joint remover

(suitable tool) from coming off.

17. Remove axle from vehicle.

INSPECTION AFTER REMOVAL

Check for deformity, cracks and damage on each parts, replace if necessary.

Ball Joint Inspection

Check for boot breakage, axial looseness, and torque of suspension arm ball joint. Refer to

.

INSTALLATION

• Refer to "Removal and Installation" for tightening torque. Install in the reverse order of removal.

NOTE:

Refer to component parts location and do not reuse non-reusable parts.

• Perform final tightening of installation position of suspension links (rubber bushing) under unladen conditions

with tires on level ground, Check wheel alignment. Refer to

RSU-5, "Wheel AlignmentInspection"

• After adjusting wheel alignment, adjust neutral position of steering angle sensor. Refer to

ment of Steering Angle Sensor Neutral Position"

Disassembly and Assembly

INFOID:0000000001327528

DISASSEMBLY

Wheel Bearing

CAUTION:

Do not disassemble if wheel bearing has no trouble.

1.

Remove wheel bearing fixing bolts and anchor block fixing nuts, and remove wheel hub and bearing

assembly, back plate and anchor block from axle.

2.

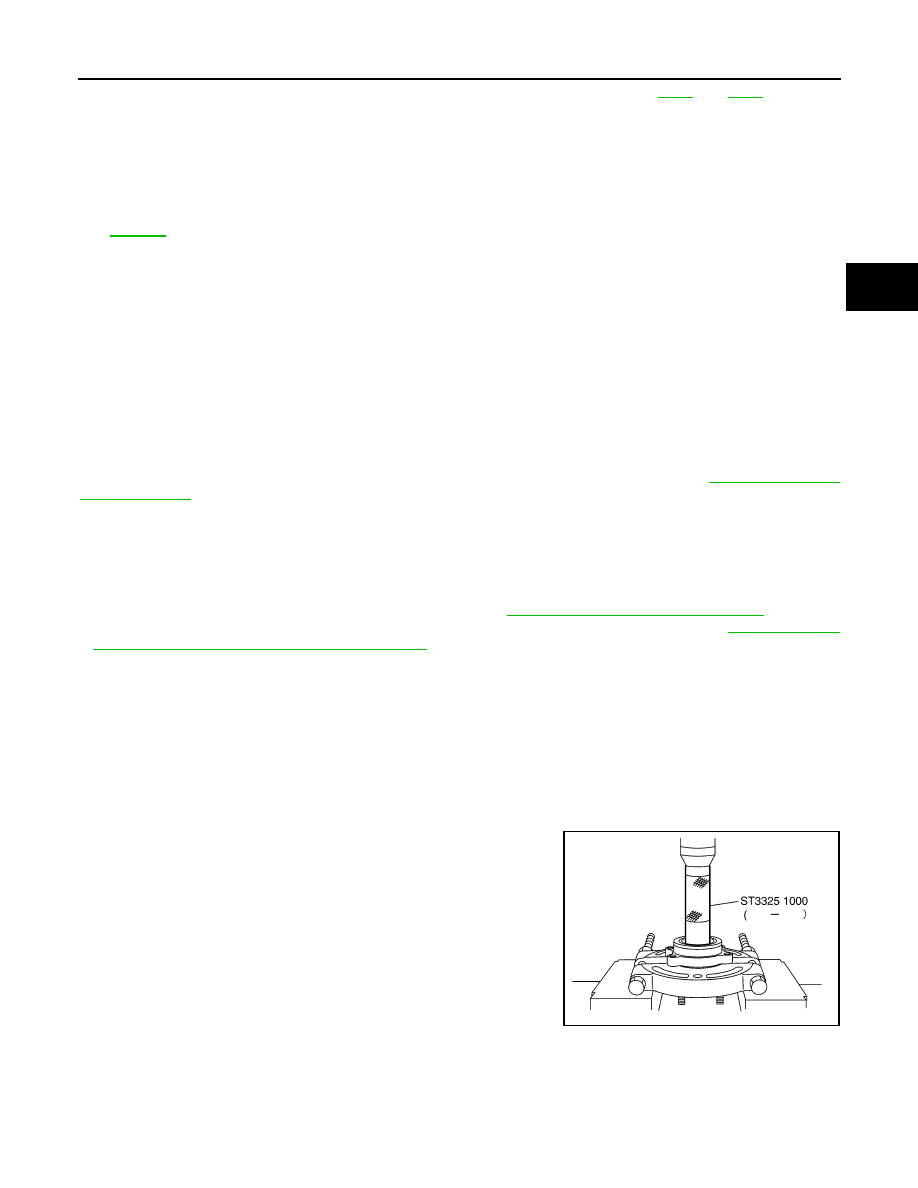

Using a drift (SST) and a puller (suitable tool), press wheel hub

out to remove from wheel bearing.

SDIA1482E