Infiniti FX35 / FX45. Manual - part 864

REAR PROPELLER SHAFT

PR-11

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

M

A

B

PR

N

O

P

1.

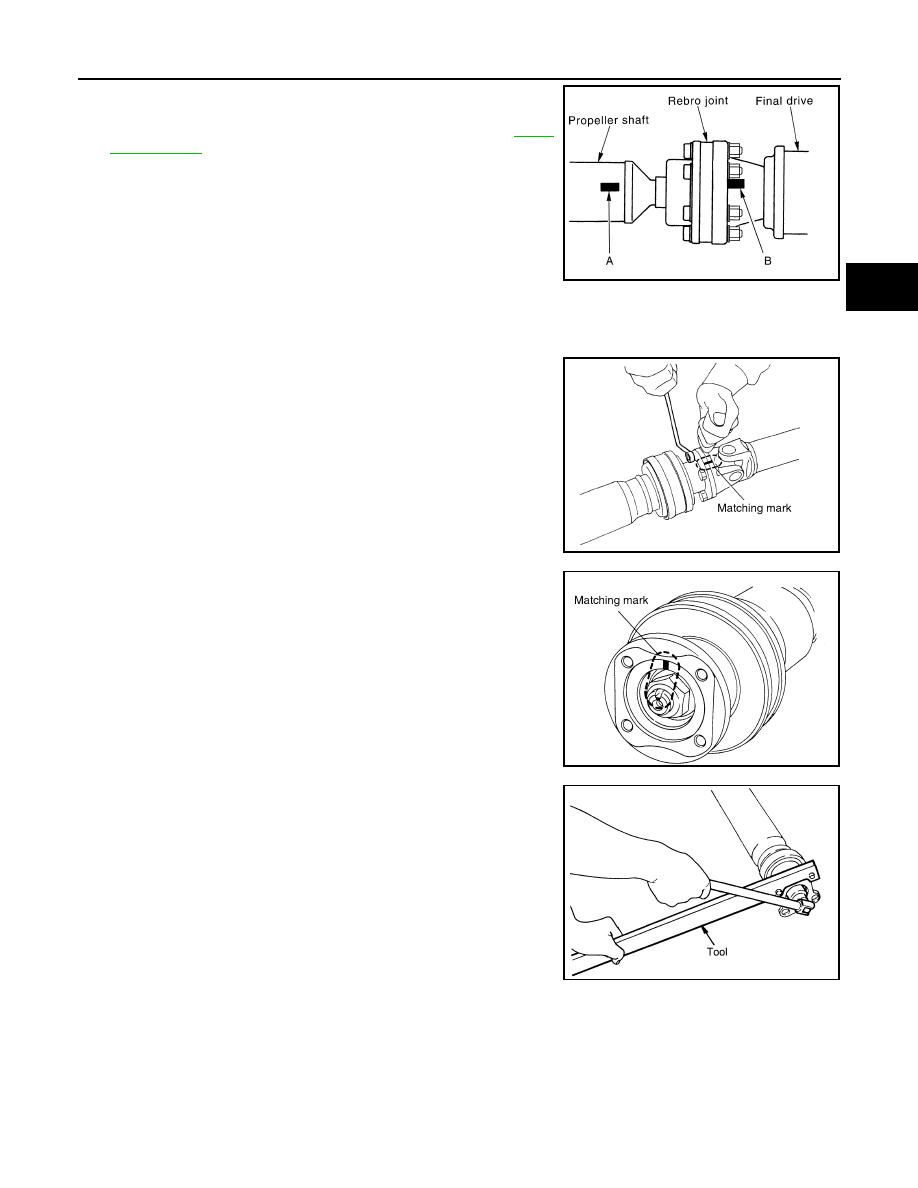

Install the propeller shaft while aligning its matching mark A with

the matching mark B on the joint as close as possible.

2.

Tighten the joint bolts to the specified torque. Refer to

.

CAUTION:

Never reuse the bolts, nuts and washers.

Disassembly and Assembly of Center Bearing

INFOID:0000000001327472

DISASSEMBLY

1.

Put matching marks on propeller shaft and center flange, then

disassemble the 1st and 2nd propeller shaft.

CAUTION:

For matching mark, use paint. Never damage the propeller

shaft flange and center flange.

2.

Put matching marks onto the center flange and propeller shaft

end as shown.

CAUTION:

For matching mark, use paint. Never damage propeller shaft

end and center flange.

3.

Hold the center flange using the flange wrench, and remove the

lock nut.

4.

Remove the center flange using a commercial available bearing

puller then remove washer.

SDIA2049E

SDIA1538E

SDIA1539E

Tool number

: KV40104000 (

—

)

SDIA1540E