Infiniti FX35 / FX45. Manual - part 836

MA-24

< SERVICE INFORMATION >

ENGINE MAINTENANCE (VK45DE ENGINE)

3.

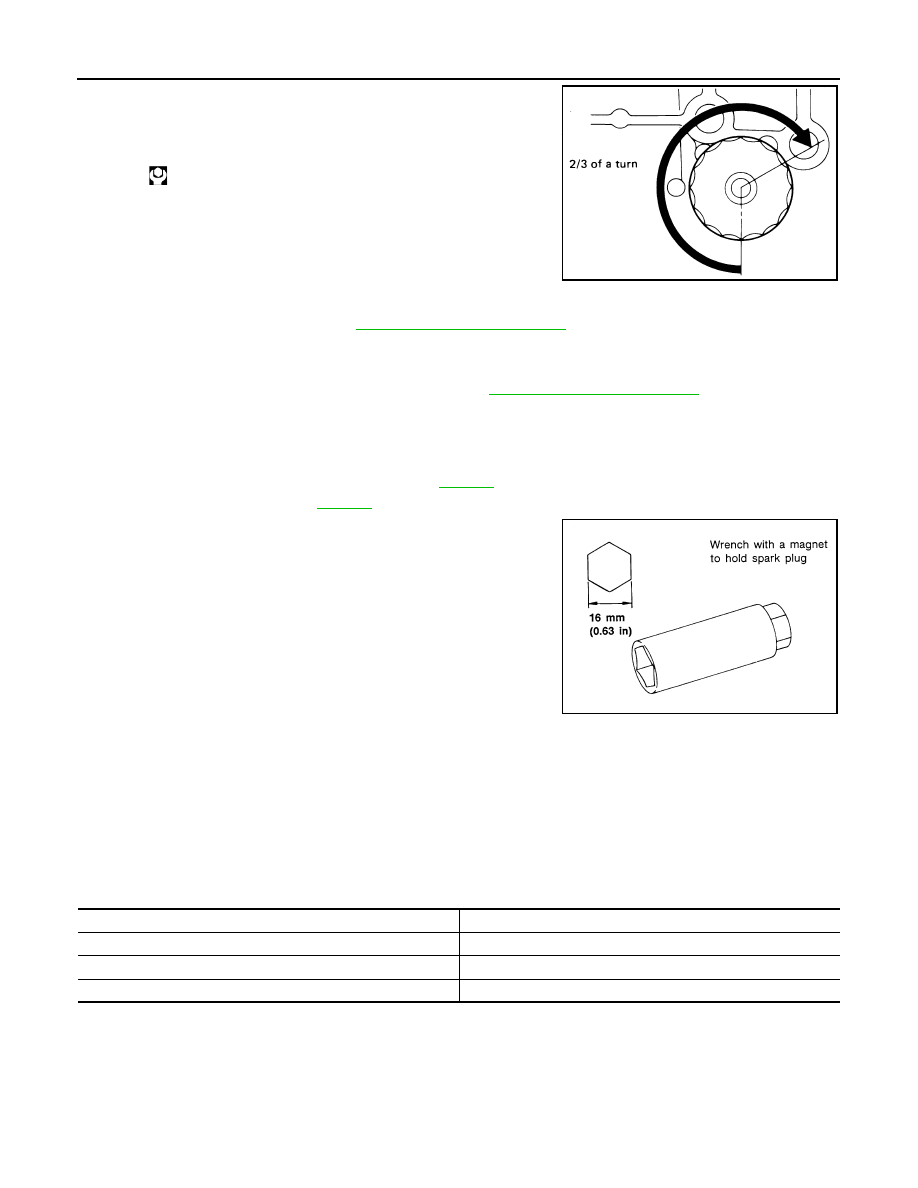

Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to specification.

INSPECTION AFTER INSTALLATION

1.

Check the engine oil level. Refer to

2.

Start engine, and check there is no leaks of engine oil.

3.

Stop engine and wait for 15 minutes.

4.

Check the engine oil level and add engine oil. Refer to

Changing Spark Plugs (Platinum-Tipped Type)

INFOID:0000000001328916

REMOVAL

1.

Remove engine cover with power tool. Refer to

2.

Remove ignition coil. Refer to

.

3.

Remove spark plug with spark plug wrench (commercial service

tool).

CAUTION:

Do not drop or shock it.

INSPECTION AFTER REMOVAL

Use standard type spark plug for normal condition.

Hot type spark plug is suitable when fouling occurs with standard type spark plug under conditions such as:

• Frequent engine starts

• Low ambient temperatures

Cold type spark plug is suitable when spark plug knock occurs with standard type spark plug under conditions such as:

• Extended highway driving

• Frequent high engine revolution

CAUTION:

• Do not drop or shock spark plug.

Oil filter:

:17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

SEM294A

Make

NGK

Standard type

PLFR5A-11

Hot type

PLFR4A-11

Cold type

PLFR6A-11

Gap (Nominal)

: 1.1 mm (0.043 in)