Infiniti FX35 / FX45. Manual - part 829

LU-28

< SERVICE INFORMATION >

[VK45DE]

OIL COOLER

6.

Remove water pipe, as necessary.

INSPECTION AFTER REMOVAL

Oil Cooler

Check oil cooler for cracks. Check oil cooler for clogging by blowing through engine coolant inlet. If necessary,

replace oil cooler.

Relief Valve

Check relief valve for movement, cracks and breaks by pushing the ball. If replacement is necessary, remove

relief valve by prying it out with suitable tool. Install a new valve in place by tapping it.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Make sure that no foreign objects are adhering to the installation planes of oil cooler or oil pan.

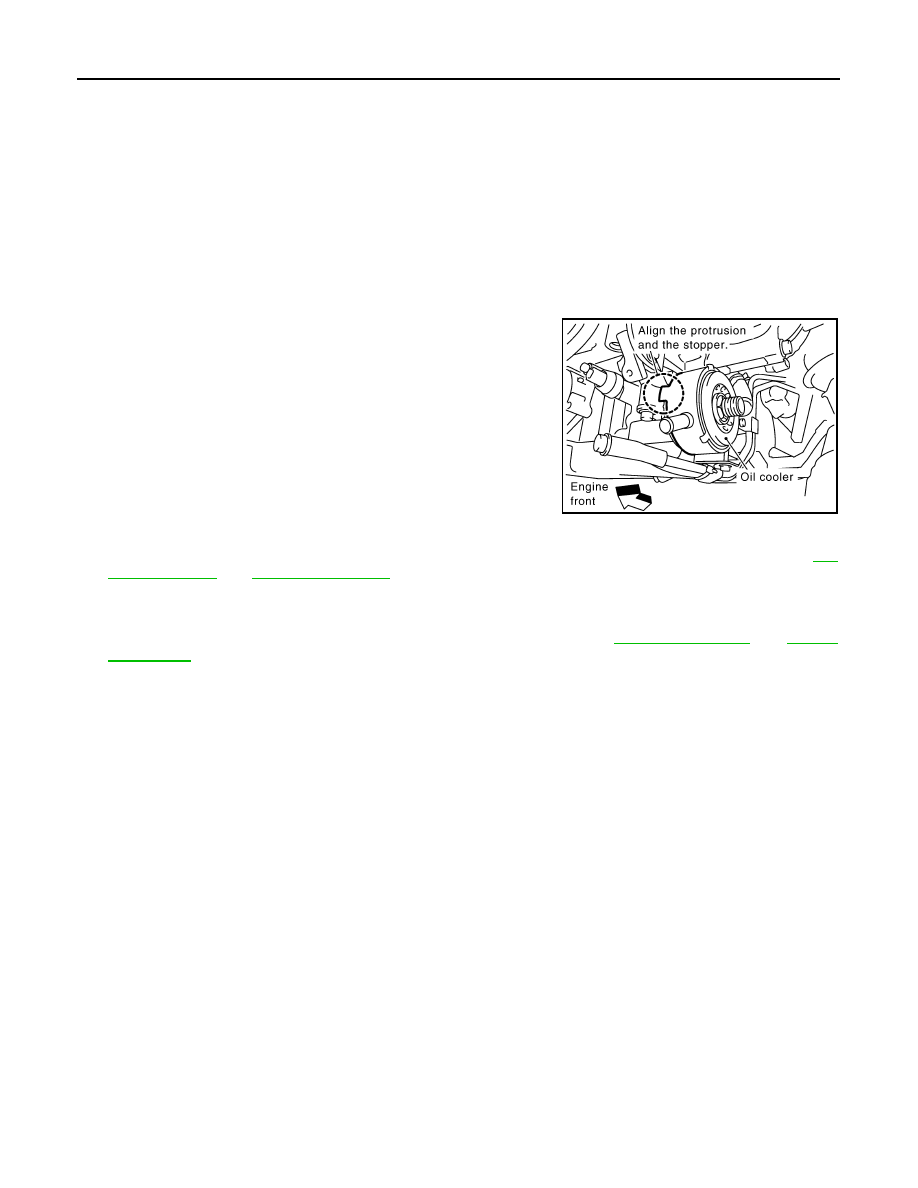

• Tighten connector bolt after aligning stopper on the oil pan side

with protrusion of oil cooler.

INSPECTION AFTER INSTALLATION

1.

Make sure level of engine oil and engine coolant, and adjust engine oil and engine coolant. Refer to

2.

Start engine, and make sure there is no leak of engine oil or engine coolant.

3.

Stop engine and wait for 15 minutes.

4.

Check the engine oil level and the engine coolant level again. Refer to

PBIC1527E