Infiniti FX35 / FX45. Manual - part 714

TRANSVERSE LINK

FSU-13

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

M

A

B

FSU

N

O

P

TRANSVERSE LINK

Removal and Installation

INFOID:0000000001327542

REMOVAL

1.

Remove tire from vehicle with power tool.

2.

Remove undercover with power tool.

3.

Remove front cross bar.

4.

Remove cotter pin at transverse link, then loosen mounting nut.

5.

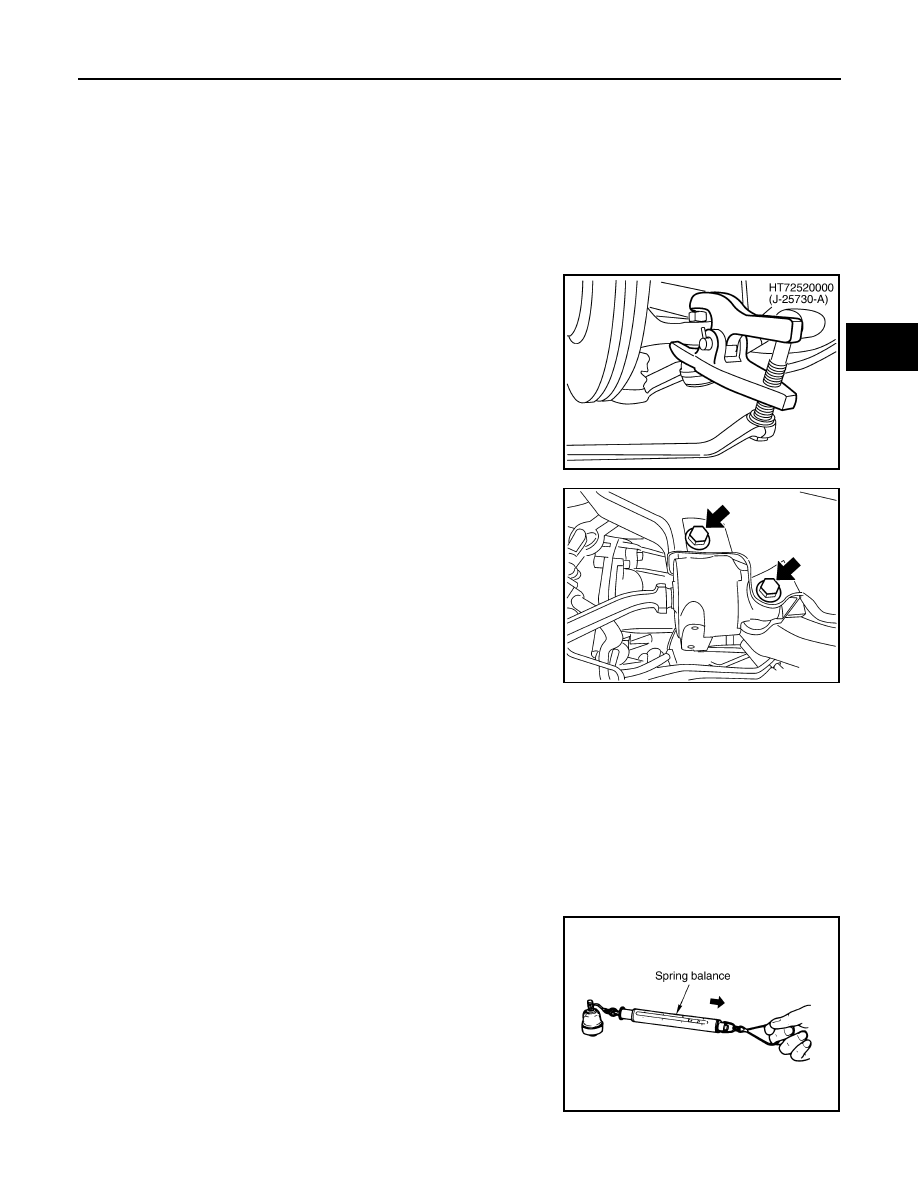

Use a ball joint remover (SST) to remove transverse link from

steering knuckle. Be careful not to damage ball joint boot.

CAUTION:

Tighten temporarily mounting nut to prevent damage to

threads and to prevent ball joint remover (SST) from com-

ing off.

6.

Remove mounting bolts which are at the back of transverse link

(mounting part with body) with power tool, separate transverse

link.

7.

Remove mounting bolts which are at the front of transverse link

(mounting part with front suspension member) with power tool,

separate transverse link.

8.

Remove transverse link from vehicle.

INSPECTION AFTER REMOVAL

Visual Inspection

• Check transverse link and bushing for deformation, cracks, or damage. If any non-standard condition is

found, replace it.

• Check boot of ball joint for cracks, or other damage, and also for grease leakage. If any non-standard condi-

tion is found, replace it.

Ball Joint Inspection

Manually move ball stud to confirm it moves smoothly with no binding.

Swing Torque Inspection

NOTE:

Before measurement, move ball joint at least ten times by hand to check for smooth movement.

• Hook spring balance at ball stud. Confirm spring balance measure-

ment value is within the specifications when ball stud begins mov-

ing.

• If it is outside the specified range, replace transverse link assem-

bly.

Rotating Torque Inspection

PEIA0109E

SEIA0331E

Swing torque:

Less than 0.5

−

4.9 N·m (0.06

−

0.49 kg-m, 5

−

43 in-lb)

Measure value of spring scale:

Less than 0.5

−

4.9 N·m (0.06

−

0.49 kg-m, 5

−

43 in-lb)

SEIA0523E