Infiniti FX35 / FX45. Manual - part 705

FFD-30

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

3.

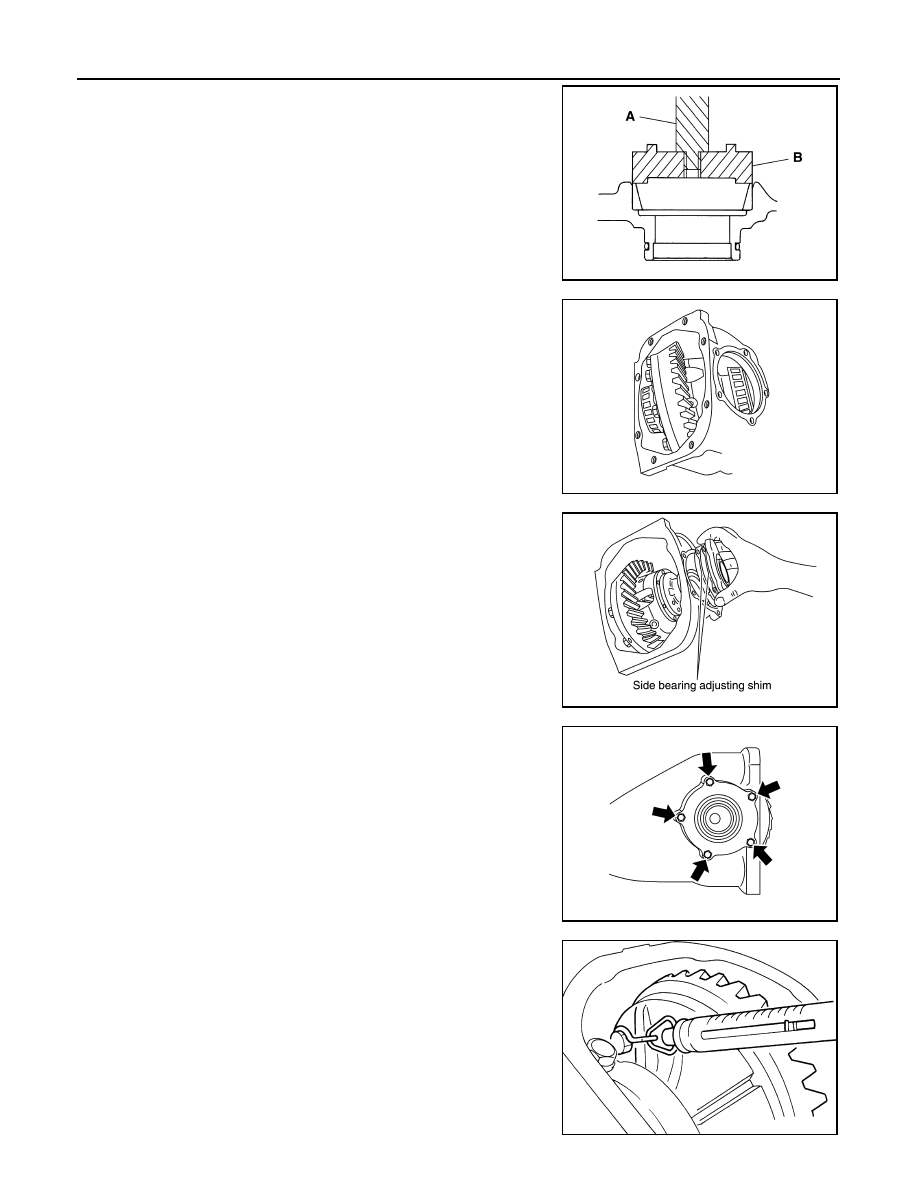

Press-fit side bearing outer race into gear carrier with tool.

CAUTION:

• At first, using a hammer, tap bearing outer race until it

becomes flat to gear carrier.

• Never reuse side bearing outer race.

4.

Place the differential case assembly into gear carrier.

5.

Install side bearing adjusting shim before disassembling or shim

which thickness is the same as the one before disassembling.

6.

Install side retainer assembly to gear carrier.

CAUTION:

Never install O-ring.

7.

Install side retainer mounting bolts to the specified torque. Refer

to "COMPONENTS (VQ35DE MODELS)", "COMPONENTS

(VK45DE MODELS)".

8.

Measure the turning torque of the gear carrier at the drive gear

mounting bolts with a spring gauge.

Tool number

A: ST30611000 (J-25742-1)

B: KV31103000 (J-38982)

PDIA0812J

PDIA0671E

PDIA0678E

PDIA0669E

Tool number

:

—

(J-8129)

Specification:

34.2 - 39.2 N (3.5 - 4.0 kg, 7.7 - 8.8 lb) of pulling force at

the drive gear bolt

SPD194A