Infiniti FX35 / FX45. Manual - part 682

CYLINDER BLOCK

EM-245

< SERVICE INFORMATION >

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

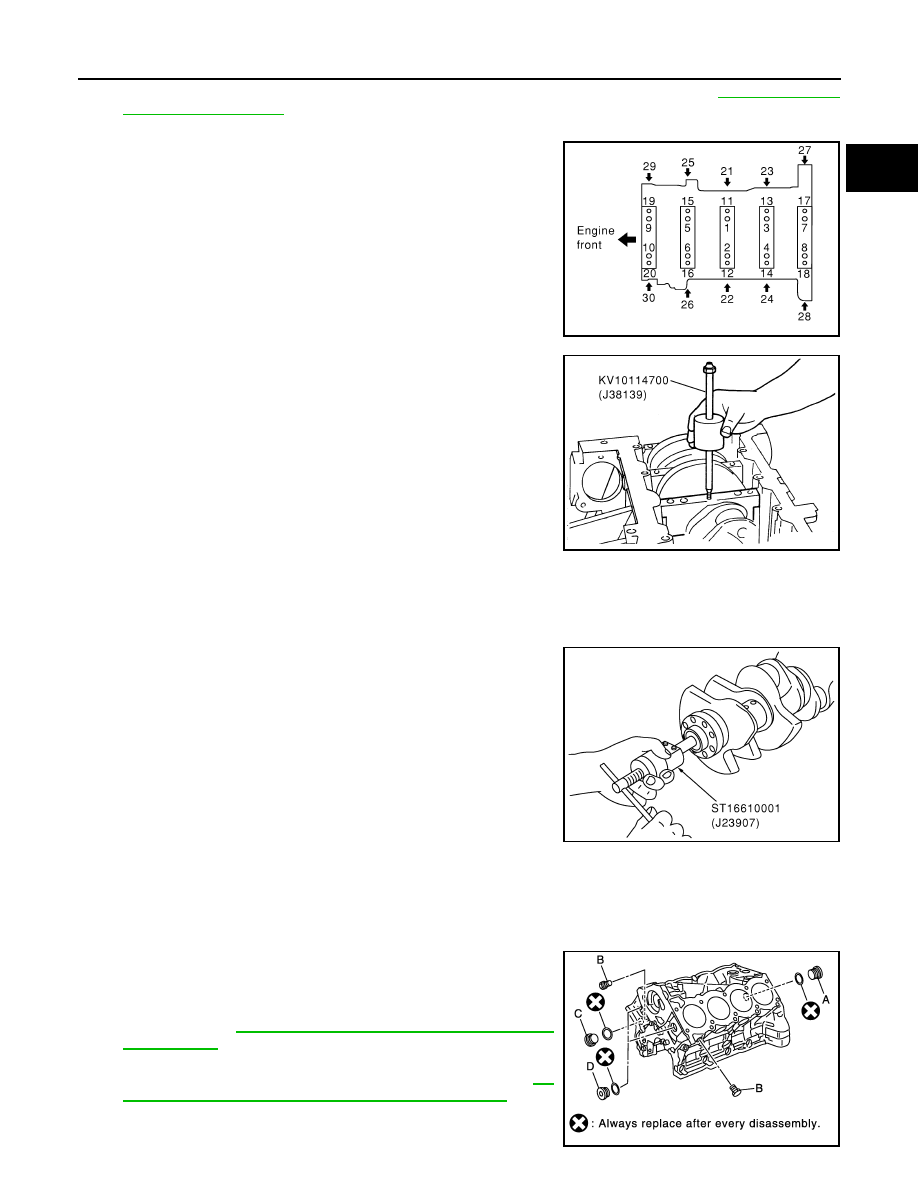

• Before loosening main bearing cap bolts, measure the crankshaft end play. Refer to

.

• Loosen main bearing cap bolts in several different steps.

a.

Remove cover attached to the rear left side of cylinder block

(next to the starter motor housing).

NOTE:

Bolts (No. 27 shown in the figure) are installed on the inside of

cover.

b.

Loosen side bolts (M10) starting from 30 to 21 to remove.

c.

Loosen main bearing cap sub bolts (M9) starting from 20 to 11 to

remove.

d.

Loosen main bearing cap bolts (M12) starting from 10 to 1 to

remove.

e.

Using main bearing cap remover (SST), remove main bearing

cap.

15. Remove crankshaft.

16. Remove main bearings and thrust bearings from cylinder block and main bearing caps.

CAUTION:

Identify installation positions, and store them without mixing them up.

17. If pilot converter must be removed, remove it from the rear end

of the crankshaft using pilot bushing puller (SST).

• It is possible to remove pilot converter without hoisting engine

with engine stand.

ASSEMBLY

1.

Fully air-blow engine coolant and engine oil passages in cylinder block, cylinder bore and crankcase to

remove any foreign material.

CAUTION:

Use a goggles to protect your eye.

2.

Install each plug to the cylinder block. (Only screwed-type plugs

are shown in the figure.)

• Apply sealant to the thread of each plug “A” and “D”.

Use Genuine High Strength Locking Sealant or equiva-

lent. Refer to

GI-44, "Recommended Chemical Product

.

• Apply sealant to the thread of each plug “B” and “C”.

Use Anaerobic Liquid Gasket or equivalent. Refer to

44, "Recommended Chemical Product and Sealant"

• Replace copper washers with new ones.

PBIC0090E

PBIC0091E

PBIC0092E

PBIC1265E