Infiniti FX35 / FX45. Manual - part 666

EXHAUST MANIFOLD AND THREE WAY CATALYST

EM-181

< SERVICE INFORMATION >

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

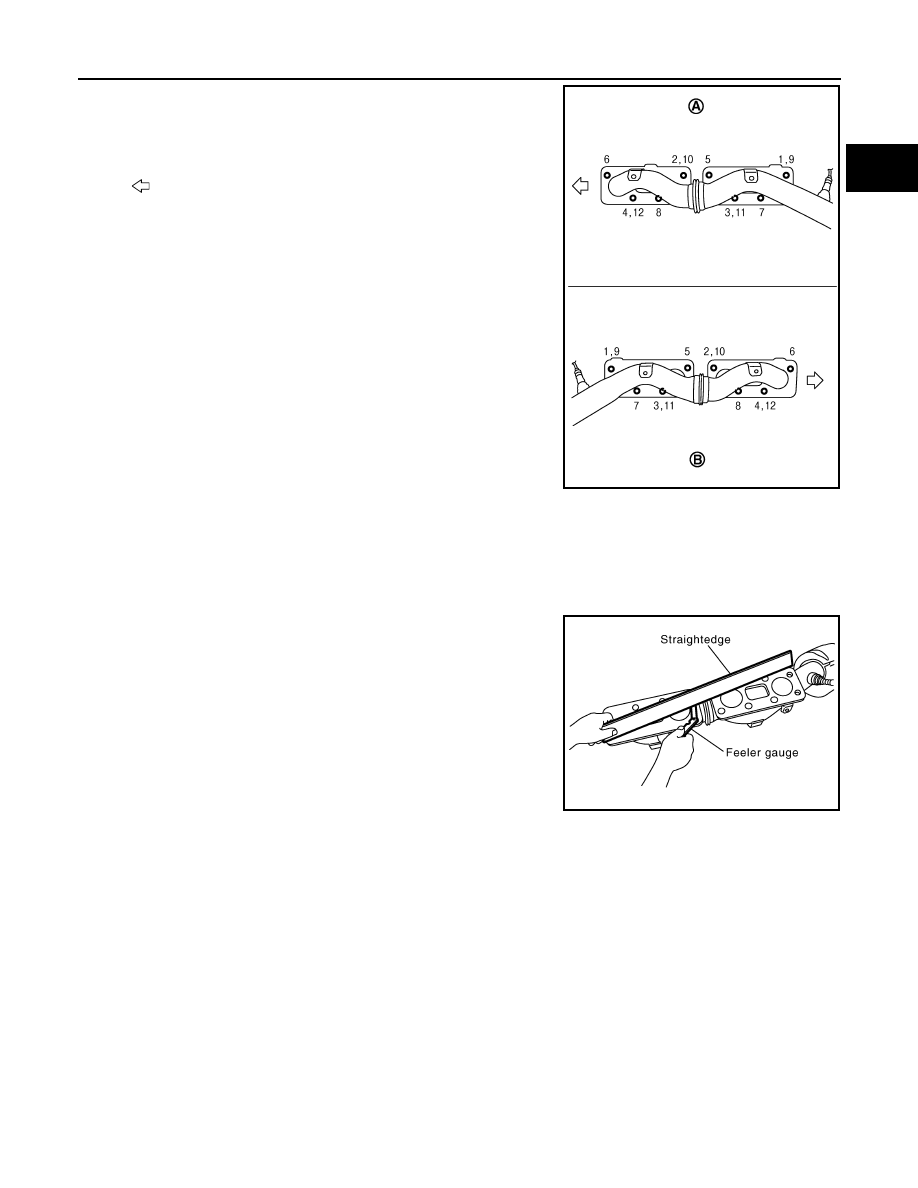

16. Loosen mounting nuts in reverse order as shown in the figure to

remove exhaust manifold.

NOTE:

Disregard the numerical order No. 9 to 12 in removal.

17. Remove exhaust manifold gaskets.

CAUTION:

Cover engine openings to avoid entry of foreign materials.

INSPECTION AFTER REMOVAL

Surface Distortion

• Check the surface distortion of the each exhaust manifold flange

mating surface with straightedge and feeler gauge.

• If it exceeds the limit, replace exhaust manifold.

INSTALLATION

Note the following, and install in the reverse order of removal.

Exhaust Manifold Gasket

Install exhaust manifold gasket with its directional protrusion set upward.

Refer to the figure of components on former page. Refer to "Removal and Installation".

Exhaust Manifold

A

: Left bank

B

: Right bank

: Engine front

PBIC3300E

Limit

: 0.3 mm (0.012 in)

PBIC1550E