Infiniti FX35 / FX45. Manual - part 653

CYLINDER BLOCK

EM-129

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

• Tighten each plug as specified below.

3.

Install oil jet.

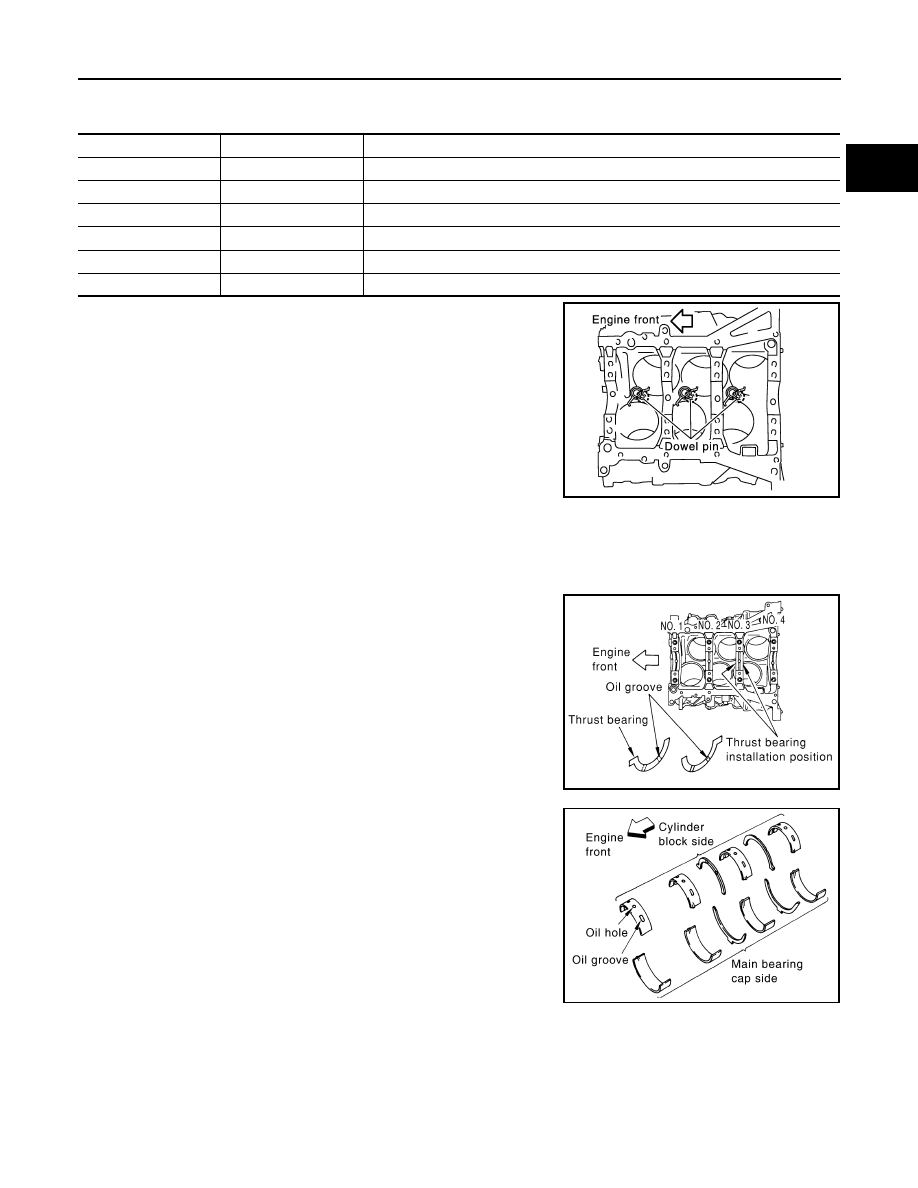

• Insert oil jet dowel pin into cylinder block dowel pin hole, and

tighten mounting bolts.

4.

Install main bearings and thrust bearings as follows:

CAUTION:

Be careful not to drop main bearing, and to scratch the surface.

a.

Remove dust, dirt, and engine oil on bearing mating surfaces of cylinder block and main bearing caps.

b.

Install thrust bearings to the both sides of the No. 3 journal hous-

ing on cylinder block and main bearing cap.

• Install thrust bearings with the oil groove facing crankshaft arm

(outside).

• Install thrust bearing with a protrusion on one end on cylinder

block, and thrust bearing with a protrusion at center on main

bearing cap. Align each protrusion with mating notch.

c.

Install main bearings paying attention to the direction.

• Main bearing with oil hole and groove goes on cylinder block.

The one without them goes on main bearing cap.

• Before installing main bearings, apply engine oil to the bearing

surface (inside). Do not apply engine oil to the back surface,

but thoroughly clean it.

• When installing, align main bearing stopper protrusion to cut-

out of cylinder block and main bearing caps.

• Ensure the oil holes on cylinder block and those on the corre-

sponding bearing are aligned.

5.

Install crankshaft to cylinder block.

• While turning crankshaft by hand, check that it turns smoothly.

6.

Install main bearing cap.

Part

Washer

Tightening torque

A

No

9.8 N·m (1.0 kg-m, 87 in-lb)

B

No

19.6 N·m (2.0 kg-m, 14 ft-lb)

C

No

19.6 N·m (2.0 kg-m, 14 ft-lb)

D

Yes

12.3 N·m (1.3 kg-m, 9 ft-lb)

E

Yes

62.0 N·m (6.3 kg-m, 46 ft-lb)

F

Yes

62.0 N·m (6.3 kg-m, 46 ft-lb)

PBIC0898E

PBIC0807E

PBIC2489E