Infiniti FX35 / FX45. Manual - part 652

CYLINDER BLOCK

EM-125

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

6.

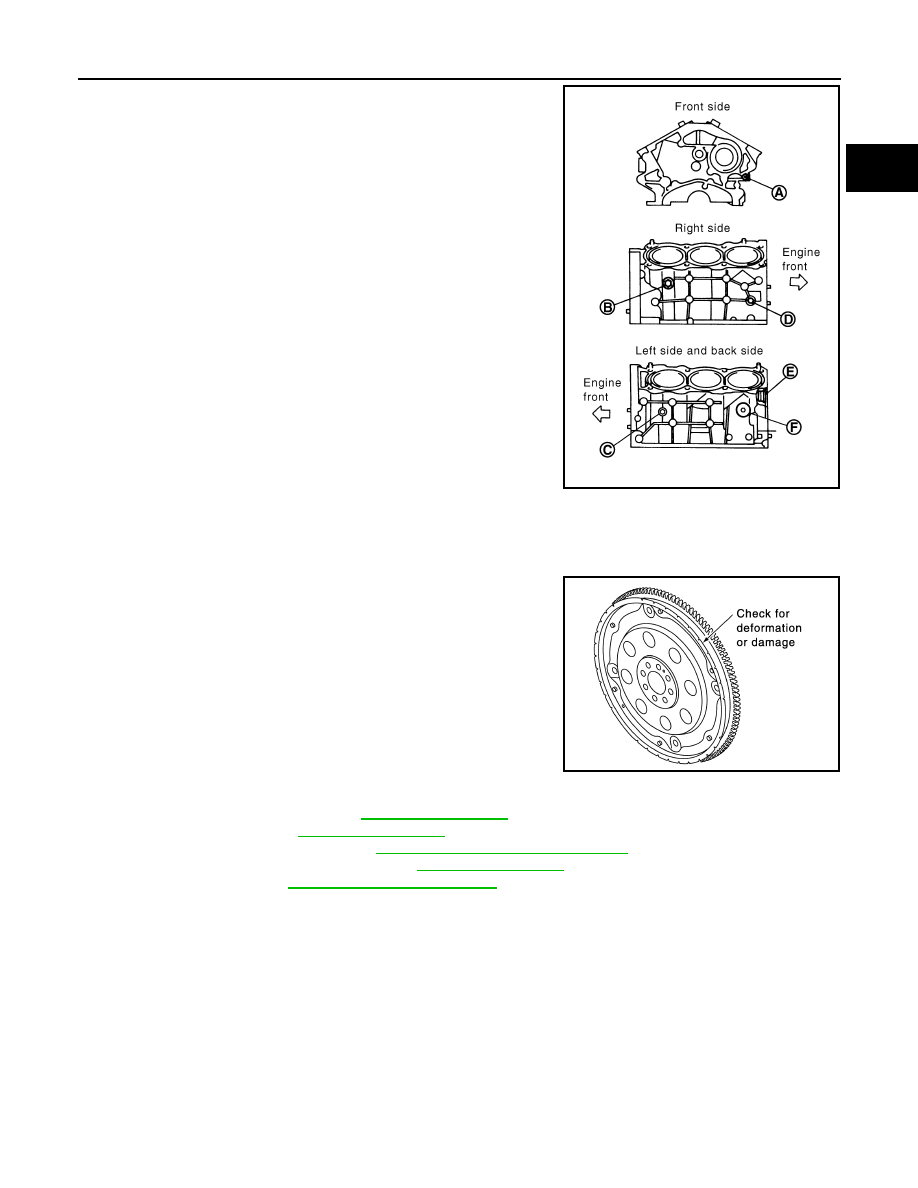

Drain engine coolant by removing water drain plugs from cylin-

der block both sides at “B” and “C” and cylinder block front side

at “A” as shown in the figure.

7.

Remove drive plate with power tool. Fix crankshaft with a ring gear stopper [SST: KV1011770 (J44716)],

and remove mounting bolts.

• Loosen mounting bolts in diagonal order.

CAUTION:

• Do not disassemble drive plate.

• Never place drive plate with signal plate facing down.

• When handling signal plate, take care not to damage or

scratch it.

• Handle signal plate in a manner that prevents it from

becoming magnetized.

8.

Remove the following parts:

• Intake manifold collector: Refer to

• Intake manifold: Refer to

.

• Oil pans (lower and upper): Refer to

EM-30, "Component (2WD Models)"

.

• Front and rear timing chain case: Refer to

.

9.

Remove knock sensor.

CAUTION:

Carefully handle sensor avoiding shocks.

PBIC2610E

SEM760G