Infiniti FX35 / FX45. Manual - part 569

DTC P1217 ENGINE OVER TEMPERATURE

EC-1037

< SERVICE INFORMATION >

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

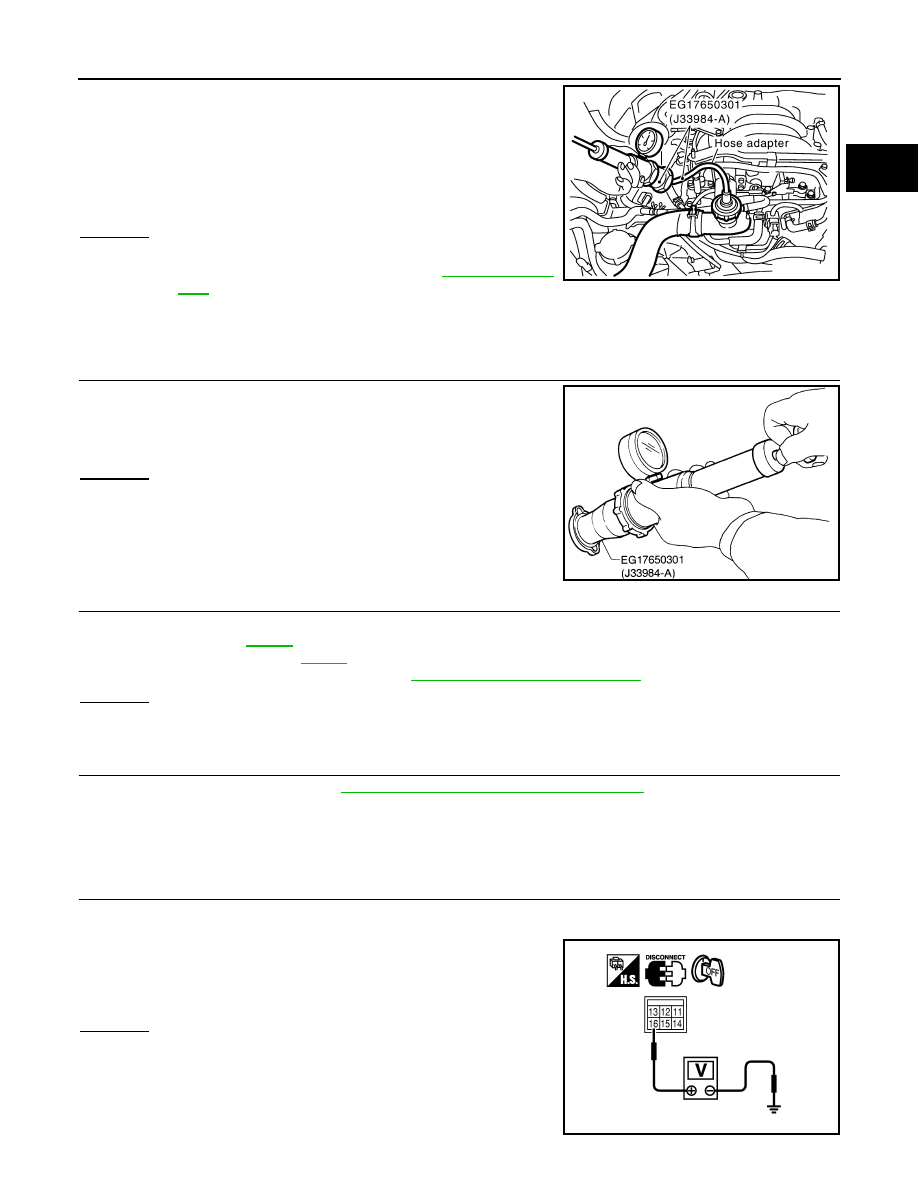

Apply pressure to the cooling system with a tester, and check if the

pressure drops.

CAUTION:

Higher than the specified pressure may cause radiator damage.

Pressure should not drop.

OK or NG

OK

>> GO TO 7.

NG

>>

Check the following for leak. Refer to

• Hose

• Radiator

• Water pump

7.

CHECK RADIATOR CAP

Apply pressure to cap with a tester.

OK or NG

OK

>> GO TO 8.

NG

>> Replace radiator cap.

8.

CHECK COMPONENT PARTS

Check the following.

• Thermostat. (Refer to

• Water control valve. (Refer to

.)

• Engine coolant temperature sensor. (Refer to

EC-783, "Component Inspection"

OK or NG

OK

>> GO TO 9.

NG

>> Replace malfunctioning component.

9.

CHECK MAIN 13 CAUSES

If the cause cannot be isolated, go to

EC-1039, "Main 13 Causes of Overheating"

>> INSPECTION END

PROCEDURE A

1.

CHECK POWER SUPPLY CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect IPDM E/R harness connector E6.

3.

Check voltage between IPDM E/R terminal 16 and ground with

CONSULT-III or tester.

OK or NG

OK

>> GO TO 3.

NG

>> GO TO 2.

Testing pressure: 157 kPa (1.6 kg/cm

2

, 23 psi)

PBIC1528E

Radiator cap

relief pressure:

59 - 98 kPa (0.6 - 1.0 kg/cm

2

, 9 - 14 psi)

SLC755A

Voltage: Battery voltage

PBIB0966E