Infiniti FX35 / FX45. Manual - part 539

DTC P0420, P0430 THREE WAY CATALYST FUNCTION

EC-917

< SERVICE INFORMATION >

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

DTC P0420, P0430 THREE WAY CATALYST FUNCTION

On Board Diagnosis Logic

INFOID:0000000001326754

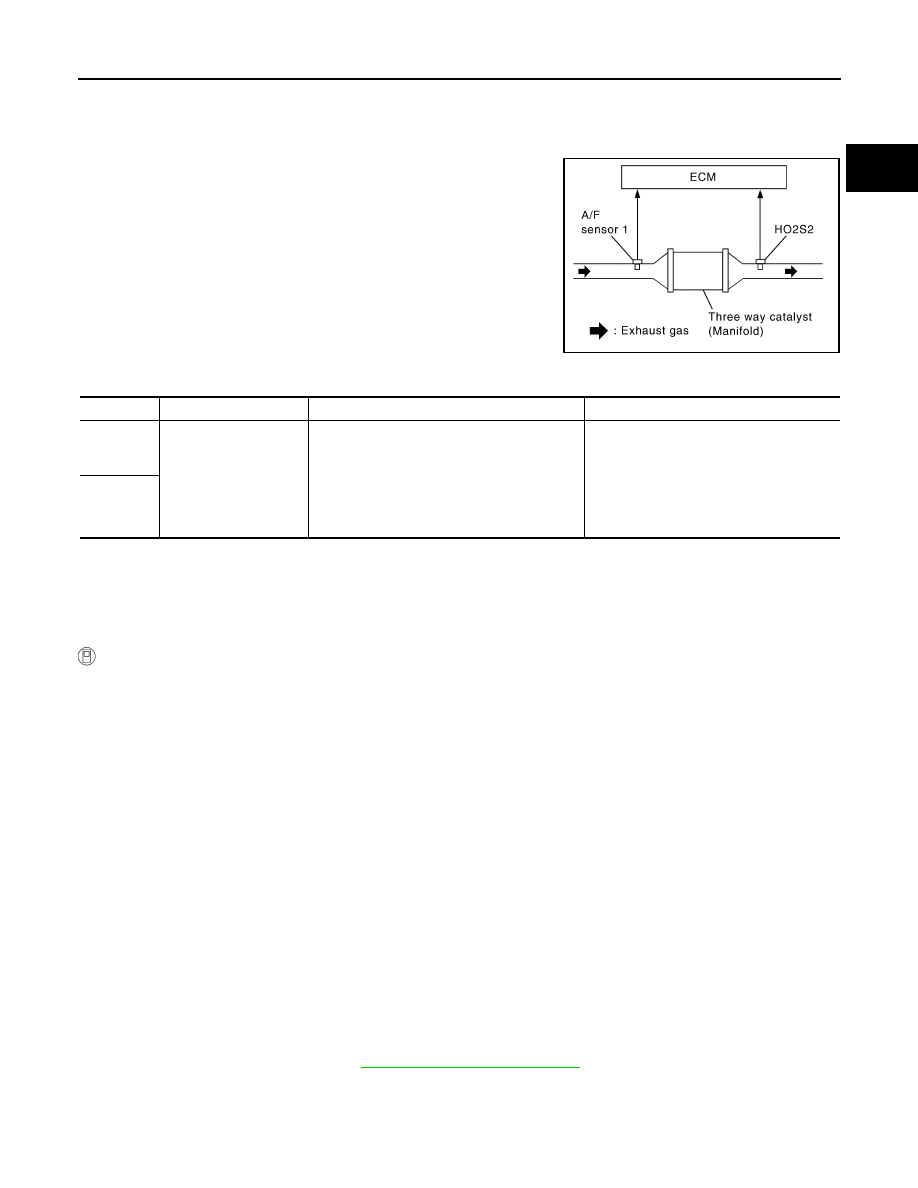

The ECM monitors the switching frequency ratio of air fuel ratio (A/F)

sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen storage capacity

will indicate a low switching frequency of heated oxygen sensor 2.

As oxygen storage capacity decreases, the heated oxygen sensor 2

switching frequency will increase.

When the frequency ratio of A/F sensor 1 and heated oxygen sensor

2 approaches a specified limit value, the three way catalyst (mani-

fold) malfunction is diagnosed.

DTC Confirmation Procedure

INFOID:0000000001326755

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-III

TESTING CONDITION:

Do not hold engine speed for more than the specified minutes below.

1.

Turn ignition switch ON and select “COOLAN TEMP/S” in “DATA MONITOR” mode with CONSULT-III.

2.

Start engine and warm it up to the normal operating temperature.

3.

Turn ignition switch OFF and wait at least 10 seconds.

4.

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

5.

Let engine idle for 1 minute.

6.

Make sure that “COOLAN TEMP/S” indicates more than 70

°

C (158

°

F).

If not, warm up engine and go to next step when “COOLAN TEMP/S” indication reaches to 70

°

C (158

°

F).

7.

Open engine hood.

8.

Select “DTC & SRT CONFIRMATION” then “SRT WORK SUPPORT” mode with CONSULT-III.

9.

Rev engine up to 2,000 to 3,000 rpm and hold it for 3 consecutive minutes then release the accelerator

pedal completely.

If “INCMP” of “CATALYST” changed to “CMPLT”, go to step 12.

10. Wait 5 seconds at idle.

11. Rev engine up to 2,000 to 3,000 rpm and maintain it until “INCMP” of “CATALYST” changes to “CMPLT” (It

will take approximately 5 minutes).

If not “CMPLT”, stop engine and cool it down to less than 70

°

C (158

°

F) and then retest from step 1.

12. Check 1st trip DTC.

13. If the 1st trip DTC is detected, go to

.

PBIB2055E

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0420

0420

(Bank 1)

Catalyst system efficien-

cy below threshold

• Three way catalyst (manifold) does not oper-

ate properly.

• Three way catalyst (manifold) does not have

enough oxygen storage capacity.

• Three way catalyst (manifold)

• Exhaust tube

• Intake air leaks

• Fuel injector

• Fuel injector leaks

• Spark plug

• Improper ignition timing

P0430

0430

(Bank 2)