Infiniti FX35 / FX45. Manual - part 393

DTC P0420, P0430 THREE WAY CATALYST FUNCTION

EC-333

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Overall Function Check

INFOID:0000000001326159

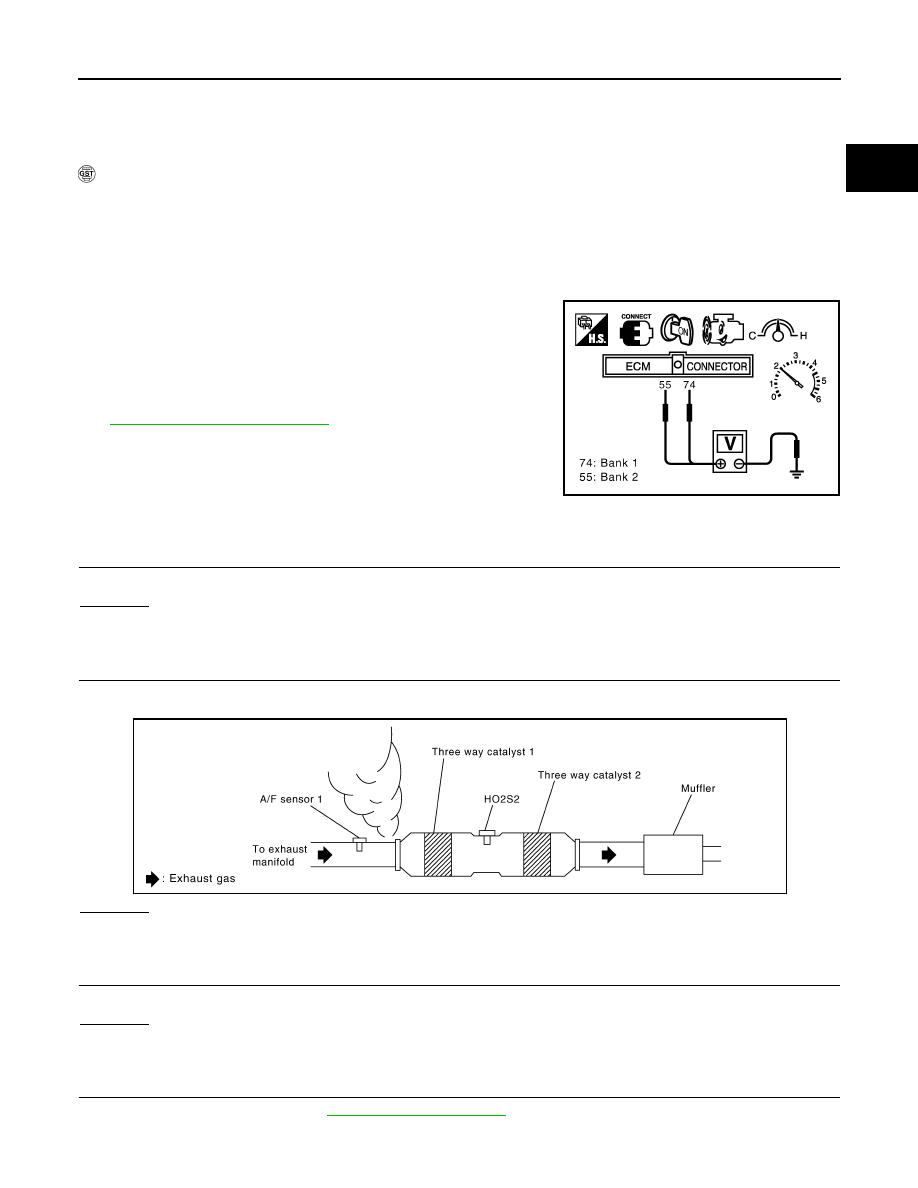

Use this procedure to check the overall function of the three way catalyst 1. During this check, a 1st trip DTC

might not be confirmed.

WITH GST

1.

Start engine and warm it up to the normal operating temperature.

2.

Turn ignition switch OFF and wait at least 10 seconds.

3.

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4.

Let engine idle for 1 minute.

5.

Open engine hood.

6.

Set voltmeter probes between ECM terminals 74 [HO2S2 (bank

1) signal], 55 [HO2S2 (bank 2) signal] and ground.

7.

Keep engine speed at 2,500 rpm constant under no load.

8.

Make sure that the voltage does not vary for more than 5 sec-

onds.

If the voltage fluctuation cycle takes less than 5 seconds, go to

• 1 cycle: 0.6 - 1.0

→

0 - 0.3

→

0.6 - 1.0

Diagnosis Procedure

INFOID:0000000001326160

1.

CHECK EXHAUST SYSTEM

Visually check exhaust tubes and muffler for dent.

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace.

2.

CHECK EXHAUST GAS LEAK

1.

Start engine and run it at idle.

2.

Listen for an exhaust gas leak before the three way catalyst 1.

OK or NG

OK

>> GO TO 3.

NG

>> Repair or replace.

3.

CHECK INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK

>> GO TO 4.

NG

>> Repair or replace.

4.

CHECK IGNITION TIMING

Check the following items. Refer to

PBIB1108E

PBIB1922E