Infiniti FX35 / FX45. Manual - part 360

DTC P0122, P0123 TP SENSOR

EC-201

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

1.

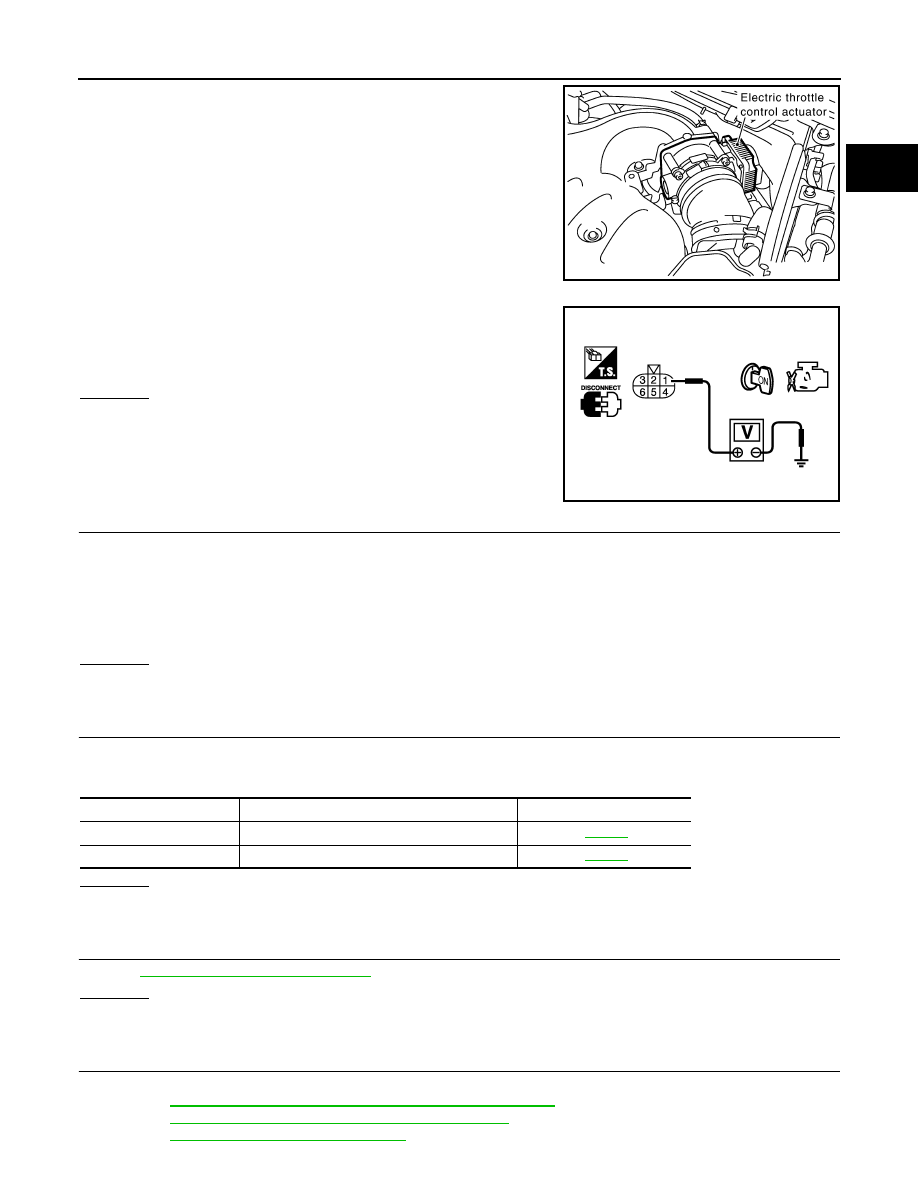

Disconnect electric throttle control actuator harness connector.

2.

Turn ignition switch ON.

3.

Check voltage between electric throttle control actuator terminal

1 and ground with CONSULT-III or tester.

OK or NG

OK

>> GO TO 7.

NG

>> GO TO 3.

3.

CHECK THROTTLE POSITION SENSOR 2 POWER SUPPLY CIRCUIT-II

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check harness continuity between electric throttle control actuator terminal 1 and ECM terminal 47.

Refer to Wiring Diagram.

OK or NG

OK

>> GO TO 4.

NG

>> Repair open circuit.

4.

CHECK THROTTLE POSITION SENSOR 2 POWER SUPPLY CIRCUIT-III

Check the following.

• Harness for short to power and short to ground, between the following terminals.

OK or NG

OK

>> GO TO 5.

NG

>> Repair short to ground or short to power in harness or connectors.

5.

CHECK APP SENSOR

EC-517, "Component Inspection"

OK or NG

OK

>> GO TO 11.

NG

>> GO TO 6.

6.

REPLACE ACCELERATOR PEDAL ASSEMBLY

1.

Replace accelerator pedal assembly.

2.

EC-85, "Accelerator Pedal Released Position Learning"

3.

EC-85, "Throttle Valve Closed Position Learning"

.

4.

EC-85, "Idle Air Volume Learning"

PBIB1557E

Voltage: Approximately 5V

PBIB0082E

Continuity should exist.

ECM terminal

Sensor terminal

Reference Wiring Diagram

47

Electric throttle control actuator terminal 1

91

APP sensor terminal 4