Infiniti FX35 / FX45. Manual - part 351

DTC P0037, P0038, P0057, P0058 HO2S2 HEATER

EC-165

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Diagnosis Procedure

INFOID:0000000001325978

1.

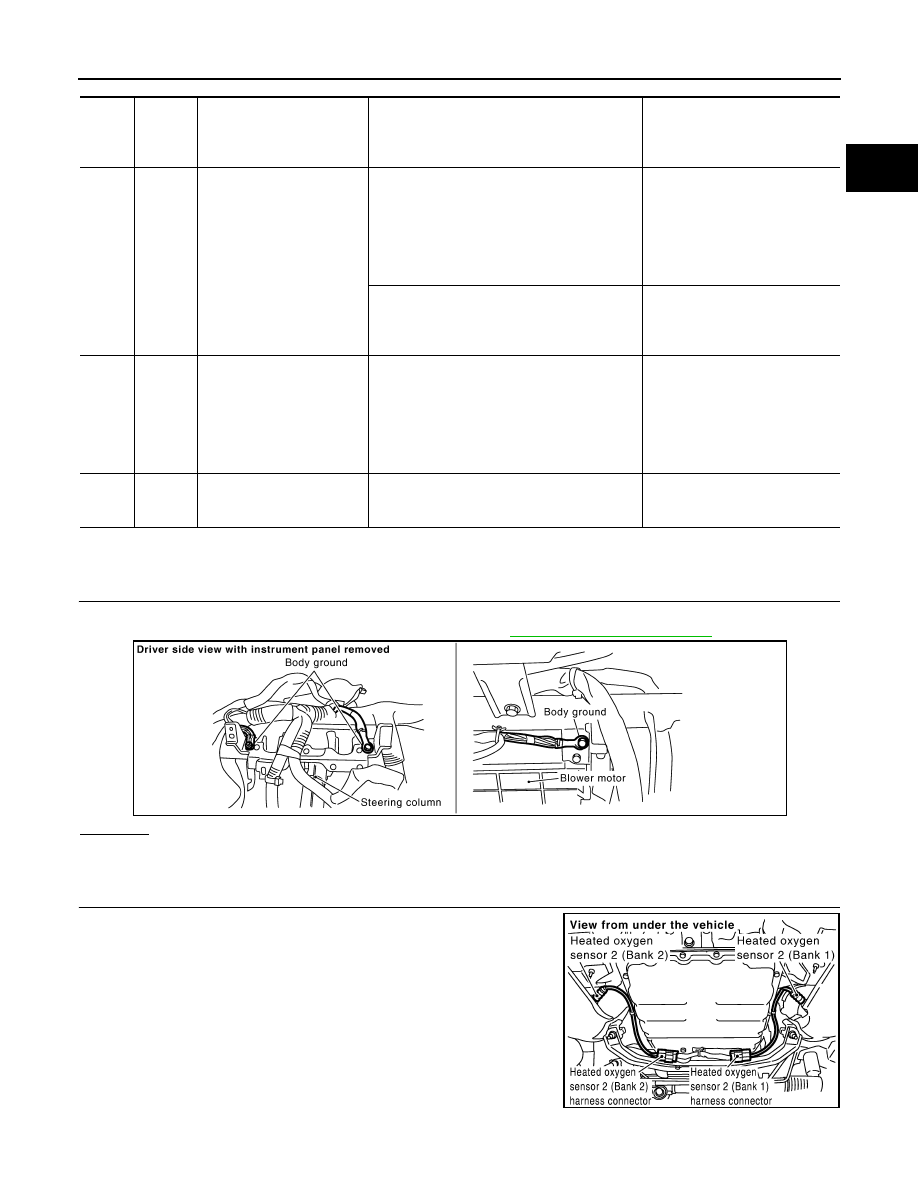

CHECK GROUND CONNECTIONS

1.

Turn ignition switch OFF.

2.

Loosen and retighten ground screw on the body. Refer to

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace ground connections.

2.

CHECK HO2S2 POWER SUPPLY CIRCUIT

1.

Disconnect heated oxygen sensor 2 harness connector.

2.

Turn ignition switch ON.

TER-

MI-

NAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

6

R

Heated oxygen sensor 2

heater (bank 2)

[Engine is running]

• Engine speed: Below 3,600 rpm after the fol-

lowing conditions are met.

- Engine: After warming up

- Keeping the engine speed between 3,500

and 4,000 rpm for 1 minute and at idle for 1

minute under no load

0 - 1.0V

[Ignition switch: ON]

• Engine stopped

[Engine is running]

• Engine speed: Above 3,600 rpm

BATTERY VOLTAGE

(11 - 14V)

55

W/R

Heated oxygen sensor 2

(bank 2)

[Engine is running]

• Revving engine from idle to 3,000 rpm quick-

ly after the following conditions are met

- Engine: After warming up

- Keeping the engine speed between 3,500

and 4,000 rpm for 1 minute and at idle for 1

minute under no load

0 - Approximately 1.0V

78

B/R

Sensor ground

(Heated oxygen sensor)

[Engine is running]

• Warm-up condition

• Idle speed

Approximately 0V

PBIB2625E

PBIB1576E