Infiniti FX35 / FX45. Manual - part 261

BRC-30

< SERVICE INFORMATION >

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Note: Serves as EBD warning lamp.

Active Test

INFOID:0000000001327674

CAUTION:

• Do not perform active test while driving vehicle.

• Make sure to completely bleed air from the brake system.

• Active test can not be performed when EBD, ABS, TCS or VDC operation is malfunction.

• ABS and brake warning lamps turn on during the active test.

NOTE:

RR LH IN SOL

(ON/OFF)

×

Rear LH IN ABS solenoid (ON/OFF) status is displayed.

RR LH OUT SOL

(ON/OFF)

×

Rear LH OUT ABS solenoid (ON/OFF) status is displayed.

OFF LAMP

(ON/OFF)

×

OFF Lamp (ON/OFF) status is displayed.

MOTOR RELAY

(ON/OFF)

×

ABS motor relay signal (ON/OFF) status is displayed.

ACTUATOR RLY

(ON/OFF)

×

ABS actuator relay signal (ON/OFF) status is displayed.

CV1

(ON/OFF)

Primary side switch-over solenoid valve 1 (cut valve 1) (ON/OFF) status

is displayed.

CV2

(ON/OFF)

Secondary side switch-over solenoid valve 2 (cut-valve 2) (ON/OFF)

status is displayed.

SV1

(ON/OFF)

Primary side switch-over solenoid valve 1 (suction valve 1) (ON/OFF)

status is displayed.

SV2

(ON/OFF)

Secondary side switch-over solenoid valve 2 (suction valve 2) (ON/

OFF) status is displayed.

VDC FAIL SIG

(ON/OFF)

VDC fail signal (ON/OFF) status is displayed.

TCS FAIL SIG

(ON/OFF)

TCS fail signal (ON/OFF) status is displayed.

ABS FAIL SIG

(ON/OFF)

ABS fail signal (ON/OFF) status is displayed.

EBD FAIL SIG

(ON/OFF)

EBD fail signal (ON/OFF) status is displayed.

EBD SIGNAL

(ON/OFF)

EBD operation (ON/OFF) status is displayed.

ABS SIGNAL

(ON/OFF)

ABS operation (ON/OFF) status is displayed.

TCS SIGNAL

(ON/OFF)

TCS operation (ON/OFF) status is displayed.

VDC SIGNAL

(ON/OFF)

VDC operation (ON/OFF) status is displayed.

EBD WARN LAMP

(ON/OFF)

Brake warning lamp (ON/OFF) status is displayed. (Note)

CRANKING SIG

(ON/OFF)

Cranking condition (ON/OFF) status is displayed.

4WD FAIL REQ

(ON/OFF)

AWD fail-safe signal (ON/OFF) status is displayed.

2WD/4WD

(2WD/4WD)

Distinguish 2WD and AWD

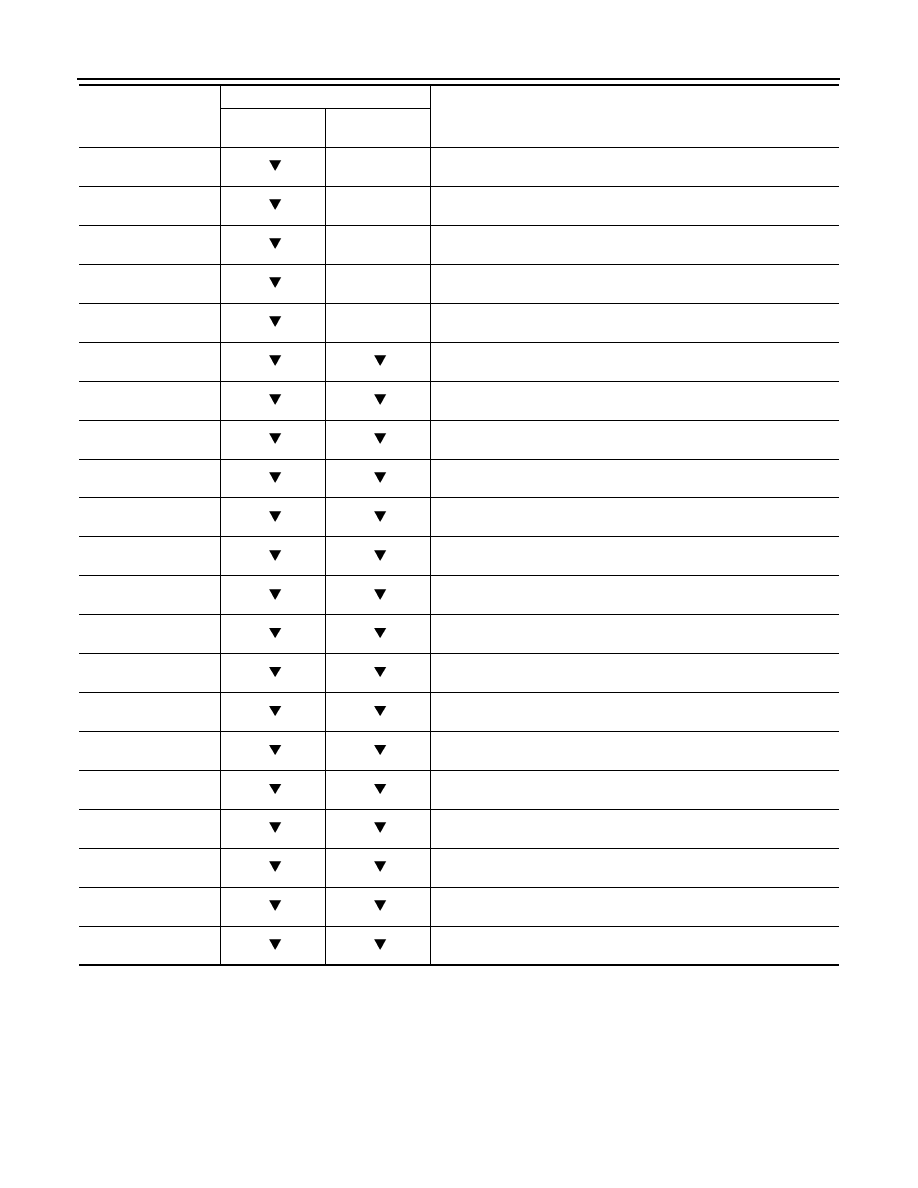

Item

(Unit)

Data monitor item selection

Remarks

ECU INPUT

SIGNALS

MAIN

SIGNALS