Infiniti FX35 / FX45. Manual - part 117

ATC-64

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

• Intake sensor

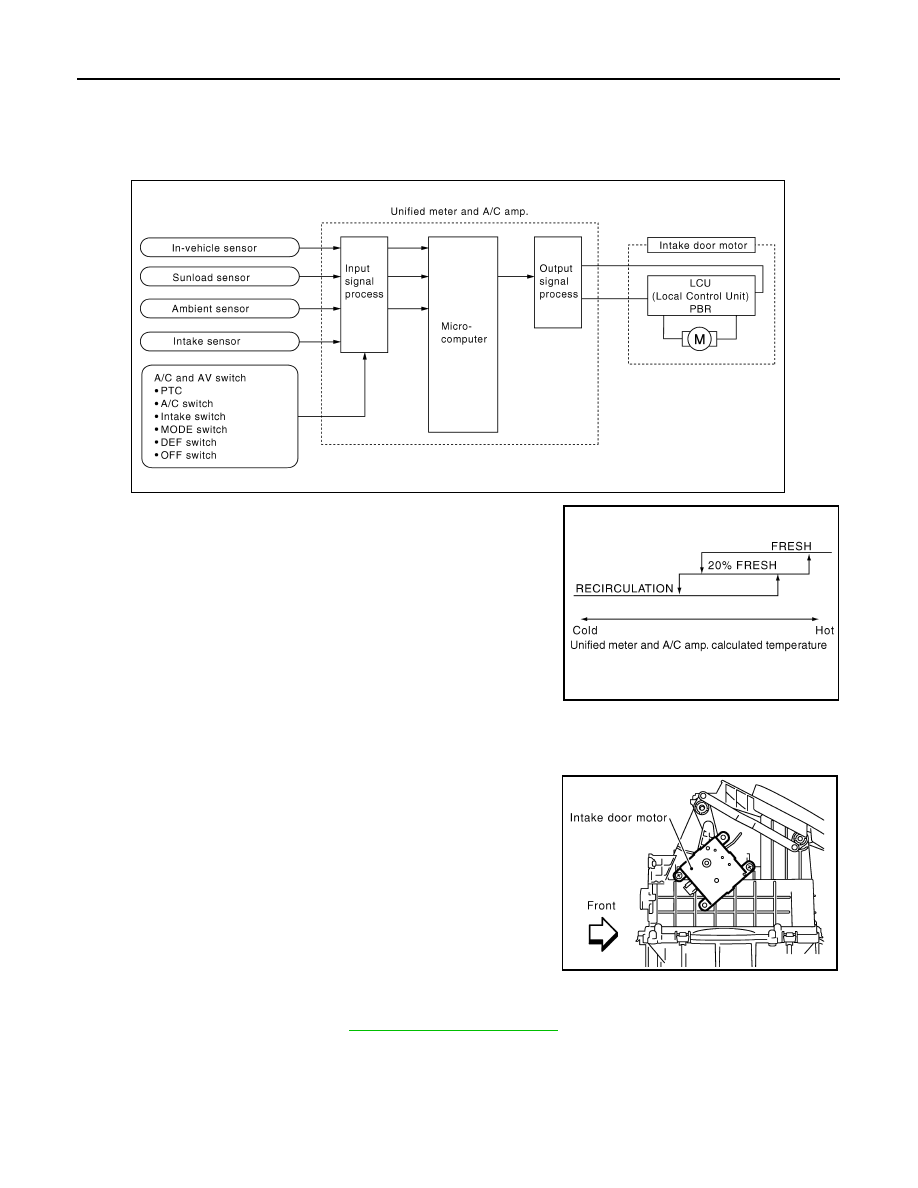

System Operation

The intake door control determines intake door position based on the ambient temperature, the intake air tem-

perature and the in-vehicle temperature. When the DEF, or OFF switches are pressed or A/C switch is OFF,

the unified meter and A/C amp. sets the intake door at the FRE position.

Intake Door Control Specification

COMPONENT DESCRIPTION

Intake Door Motor

The intake door motor is attached to the blower unit. It rotates so that

air is drawn from inlets set by the unified meter and A/C amp. Motor

rotation is conveyed to a lever which activates the intake door.

DIAGNOSIS PROCEDURE FOR INTAKE DOOR MOTOR

SYMPTOM: Intake door motor does not operate normally.

Perform diagnosis procedure. Refer to

Blower Motor Circuit

INFOID:0000000001328189

SYMPTOM: Blower motor operation is malfunctioning.

INSPECTION FLOW

SJIA1588E

RJIA1787E

RJIA0897E