Infiniti FX35 / FX45. Manual - part 98

AT-320

< SERVICE INFORMATION >

ASSEMBLY

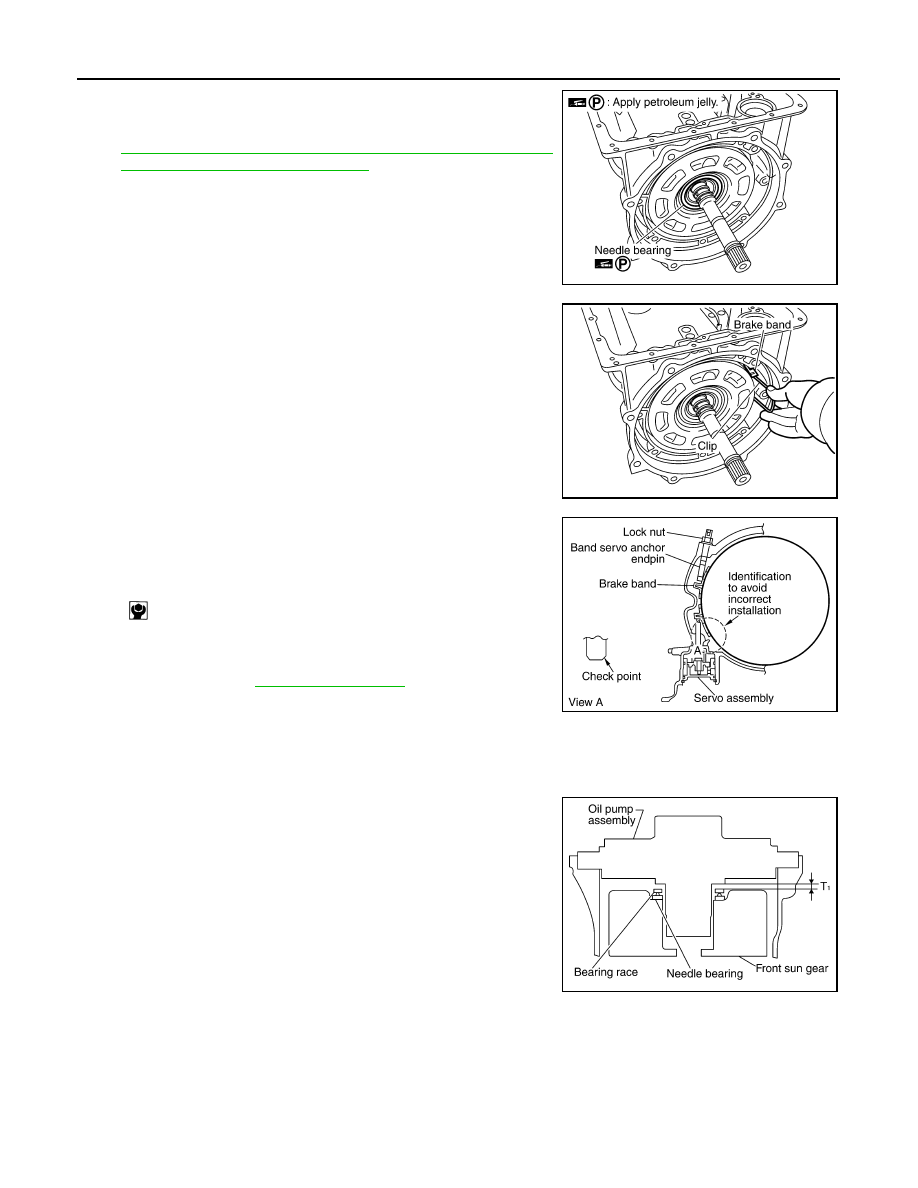

51. Install needle bearing to front sun gear.

CAUTION:

• Take care with the direction of needle bearing. Refer to

AT-264, "Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings"

.

• Apply petroleum jelly to needle bearing.

52. Adjust brake band tilting using clips so that brake band contacts

front sun gear drum evenly.

53. Adjust brake band.

a.

Loosen lock nut.

b.

Tighten band servo anchor end pin to the specified torque.

c.

Back of band servo anchor end pin three turns.

d.

Holding band servo anchor end pin, tighten lock nut to the spec-

ified torque. Refer to

.

Adjustment

INFOID:0000000001327411

TOTAL END PLAY

• Measure clearance between front sun gear and bearing race for oil

pump cover.

• Select proper thickness of bearing race so that end play is within

specifications.

SCIA2808E

SCIA5033E

: 5.0 N·m (0.51 kg-m, 44 in-lb)

SCIA5498E

SCIA2810E