Infiniti FX35, FX50 (S51). Manual - part 998

EM-292

< SERVICE DATA AND SPECIFICATIONS (SDS)

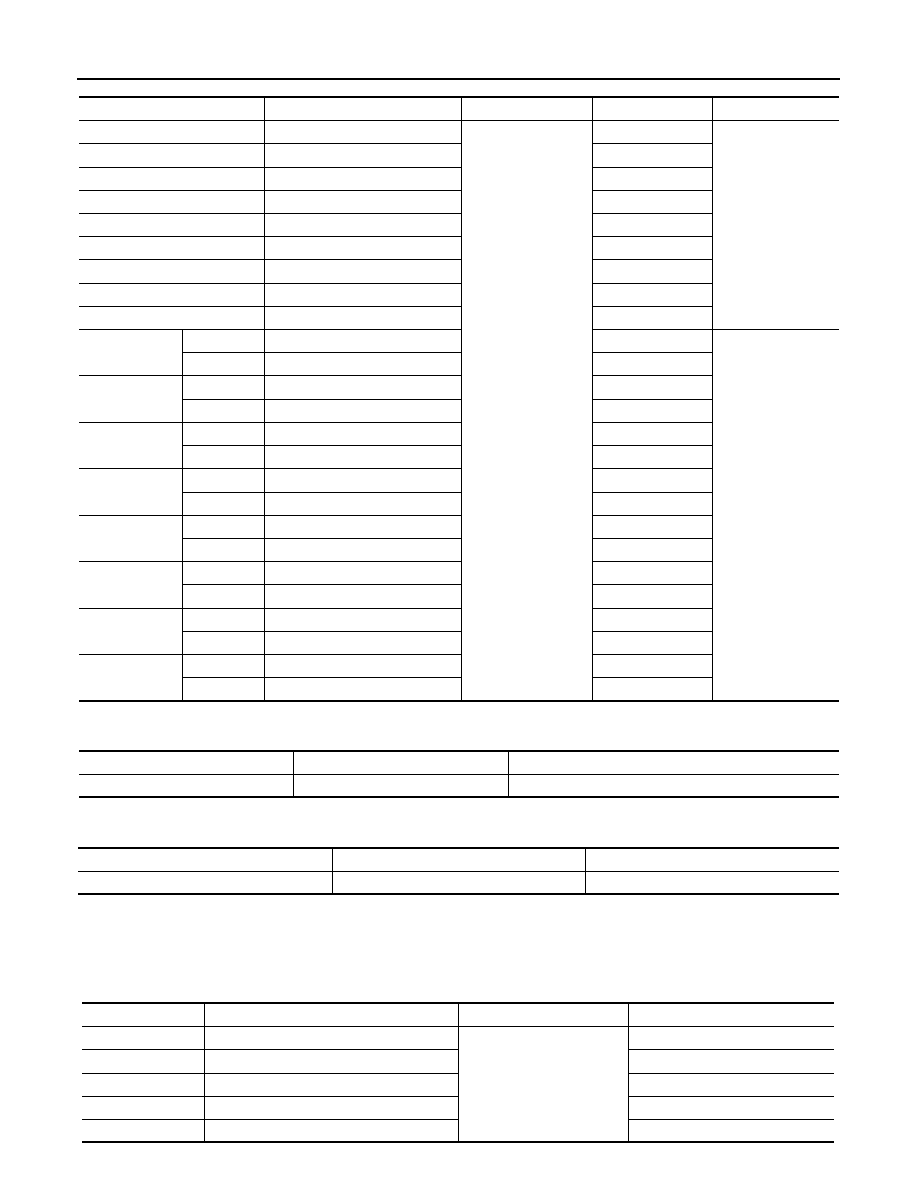

[VK50VE]

SERVICE DATA AND SPECIFICATIONS (SDS)

UNDERSIZE

Unit: mm (in)

MAIN BEARING OIL CLEARANCE

Unit: mm (in)

*: Actual clearance

Connecting Rod Bearing

INFOID:0000000005245274

CONNECTING ROD BEARING

Grade number

Thickness

mm (in)

Width

mm (in)

Identification color

Remarks

0

2.483 - 2.486 (0.0978 - 0.0979)

19.9 - 20.1

(0.783 - 0.791)

Black

Grade is the same

for upper and lower

bearings.

1

2.486 - 2.489 (0.0979 - 0.0980)

Brown

2

2.489 - 2.492 (0.0980 - 0.0981)

Green

3

2.492 - 2.495 (0.0981 - 0.0982)

Yellow

4

2.495 - 2.498 (0.0982 - 0.0983)

Blue

5

2.498 - 2.501 (0.0983 - 0.0985)

Pink

6

2.501 - 2.504 (0.0985 - 0.0986)

Purple

7

2.504 - 2.507 (0.0986 - 0.0987)

White

8

2.507 - 2.510 (0.0987 - 0.0988)

Red

01

UPR

2.483 - 2.486 (0.0978 - 0.0979)

Black

Grade and color are

different for upper

and lower bearings.

LWR

2.486 - 2.489 (0.0979 - 0.0980)

Brown

12

UPR

2.486 - 2.489 (0.0979 - 0.0980)

Brown

LWR

2.489 - 2.492 (0.0980 - 0.0981)

Green

23

UPR

2.489 - 2.492 (0.0980 - 0.0981)

Green

LWR

2.492 - 2.495 (0.0981 - 0.0982)

Yellow

34

UPR

2.492 - 2.495 (0.0981 - 0.0982)

Yellow

LWR

2.495 - 2.498 (0.0982 - 0.0983)

Blue

45

UPR

2.495 - 2.498 (0.0982 - 0.0983)

Blue

LWR

2.498 - 2.501 (0.0983 - 0.0985)

Pink

56

UPR

2.498 - 2.501 (0.0983 - 0.0985)

Pink

LWR

2.501 - 2.504 (0.0985 - 0.0986)

Purple

67

UPR

2.501 - 2.504 (0.0985 - 0.0986)

Purple

LWR

2.504 - 2.507 (0.0986 - 0.0987)

White

78

UPR

2.504 - 2.507 (0.0986 - 0.0987)

White

LWR

2.507 - 2.510 (0.0987 - 0.0988)

Red

Items

Thickness

Main journal diameter

0.25 (0.0098)

2.618 - 2.626 (0.1031 - 0.1034)

Grind so that bearing clearance is the specified value.

Items

Standard

Limit

Main bearing oil clearance

0.035 - 0.045 (0.0014 - 0.0018)*

0.065 (0.0026)

Grade number

Thickness

mm (in)

Width mm (in)

Identification color (mark)

0

1.497 - 1.500 (0.0589 - 0.0591)

18.1 - 18.3

(0.713 - 0.720)

Red

1

1.500 - 1.503 (0.0591 - 0.0592)

Black

2

1.503 - 1.506 (0.0592 - 0.0593)

Brown

3

1.506 - 1.509 (0.0593 - 0.0594)

Green

4

1.509 - 1.512 (0.0594 - 0.0595)

Yellow