Infiniti FX35, FX50 (S51). Manual - part 990

EM-260

< UNIT DISASSEMBLY AND ASSEMBLY >

[VK50VE]

CYLINDER BLOCK

• Press-fit pilot converter with its chamfering side facing crank-

shaft as shown in the figure.

5.

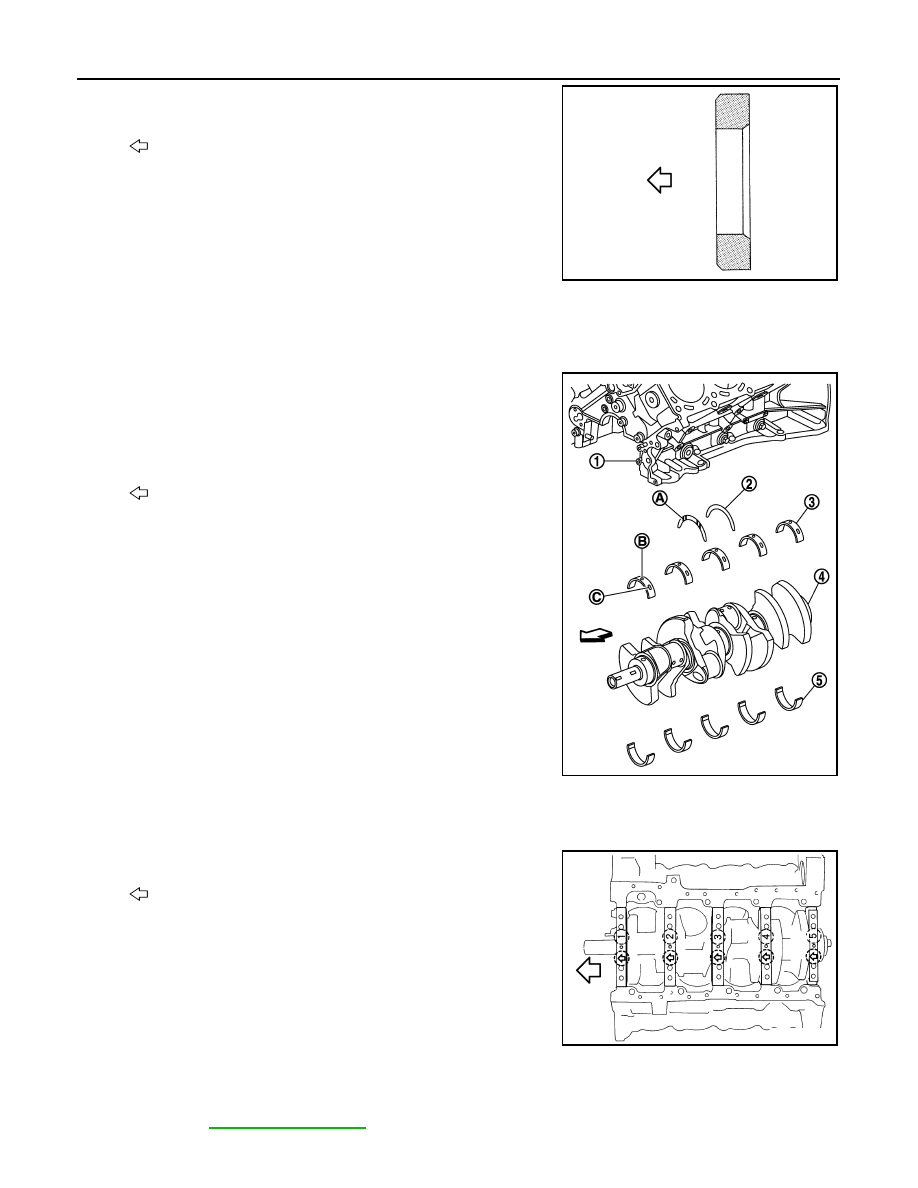

Install main bearings and thrust bearings as per the following:

CAUTION:

Be careful not to drop main bearing, and to scratch the surface.

a.

Remove dust, dirt, and engine oil on bearing mating surfaces of cylinder block and main bearing caps.

b.

Install thrust bearings (2) to both sides of the No. 3 journal hous-

ing on cylinder block (1).

• Install thrust bearings with the oil groove (A) facing crankshaft

arm (outside).

c.

Install main bearings paying attention to the direction.

• Main bearing with oil hole (B) and groove (C) goes on cylinder

block. The one without them goes on main bearing cap.

• Before installing main bearings, apply engine oil to the bearing

surface (inside). Do not apply engine oil to the back surface,

but thoroughly clean it.

• When installing, align main bearing stopper protrusion to cut-

out of cylinder block and main bearing.

• Ensure the oil holes on cylinder block and those on the corre-

sponding bearing are aligned.

6.

Install crankshaft to cylinder block.

• While turning crankshaft by hand, check that it turns smoothly.

7.

Install main bearing caps as per the following:

• Align the identification number to the journal position to install.

• Install it with the front mark (indicated by stamping) facing the

front of engine.

• Using plastic hammer or similar tool, tap them lightly to seat

them on the installation position.

NOTE:

Main bearing cap cannot be replaced as a single parts,

because it is machined together with cylinder block.

8.

Install each main bearing cap bolts as per the following:

CAUTION:

If main bearing cap bolts and sub bolts are re-used, check their outer diameters before installa-

tion. Refer to

.

: Crankshaft side

JPBIA0210ZZ

3

: Main bearing (upper) (cylinder block side)

4

: Crankshaft

5

: Main bearing (lower) (main bearing cap side)

: Engine front

JPBIA2148ZZ

: Engine front

JPBIA2380ZZ